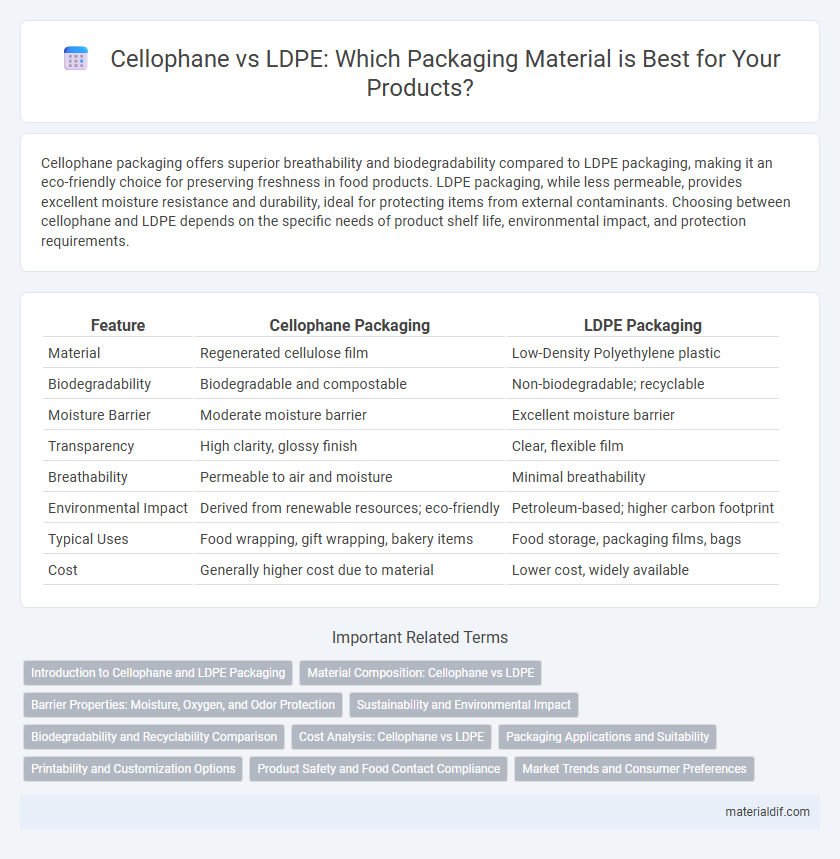

Cellophane packaging offers superior breathability and biodegradability compared to LDPE packaging, making it an eco-friendly choice for preserving freshness in food products. LDPE packaging, while less permeable, provides excellent moisture resistance and durability, ideal for protecting items from external contaminants. Choosing between cellophane and LDPE depends on the specific needs of product shelf life, environmental impact, and protection requirements.

Table of Comparison

| Feature | Cellophane Packaging | LDPE Packaging |

|---|---|---|

| Material | Regenerated cellulose film | Low-Density Polyethylene plastic |

| Biodegradability | Biodegradable and compostable | Non-biodegradable; recyclable |

| Moisture Barrier | Moderate moisture barrier | Excellent moisture barrier |

| Transparency | High clarity, glossy finish | Clear, flexible film |

| Breathability | Permeable to air and moisture | Minimal breathability |

| Environmental Impact | Derived from renewable resources; eco-friendly | Petroleum-based; higher carbon footprint |

| Typical Uses | Food wrapping, gift wrapping, bakery items | Food storage, packaging films, bags |

| Cost | Generally higher cost due to material | Lower cost, widely available |

Introduction to Cellophane and LDPE Packaging

Cellophane packaging is a transparent cellulose-based film known for its biodegradability and excellent oxygen and moisture barrier properties, making it ideal for fresh food wrapping. Low-Density Polyethylene (LDPE) packaging, a flexible plastic derived from petroleum, offers high durability, moisture resistance, and cost-effectiveness but lacks biodegradability. Both materials serve essential roles in packaging, with cellophane favored for eco-friendly needs and LDPE for versatility and strength.

Material Composition: Cellophane vs LDPE

Cellophane packaging is made from regenerated cellulose derived from wood pulp, offering biodegradability and excellent oxygen barrier properties ideal for fresh food preservation. In contrast, LDPE (low-density polyethylene) is a synthetic polymer composed of long chains of ethylene, known for flexibility, moisture resistance, and ease of heat sealing but limited biodegradability. The natural origin of cellophane makes it environmentally friendly, while LDPE's petroleum-based composition provides durability and cost-effectiveness in packaging applications.

Barrier Properties: Moisture, Oxygen, and Odor Protection

Cellophane packaging offers superior barrier properties against moisture, oxygen, and odor compared to LDPE packaging, making it an excellent choice for preserving product freshness and extending shelf life. Its natural cellulose composition provides low permeability to gases and aromas, ensuring enhanced protection for sensitive goods. In contrast, LDPE packaging exhibits higher permeability, resulting in less effective moisture and odor barriers.

Sustainability and Environmental Impact

Cellophane packaging is biodegradable and compostable, derived from renewable cellulose sources, making it a sustainable alternative to LDPE packaging, which is petroleum-based and non-biodegradable. Cellophane's ability to break down naturally reduces plastic pollution and landfill waste, whereas LDPE contributes significantly to environmental persistence and microplastic contamination. The environmental impact of cellophane is further minimized by its lower carbon footprint during production compared to LDPE plastics.

Biodegradability and Recyclability Comparison

Cellophane packaging, made from cellulose, is fully biodegradable and compostable, breaking down naturally within weeks without leaving harmful residues. LDPE packaging, derived from petrochemicals, has limited biodegradability and can persist in the environment for hundreds of years, posing plastic pollution risks. While LDPE is widely recyclable through specific plastic recycling streams, cellophane's compostability offers a more sustainable end-of-life option aligned with circular economy principles.

Cost Analysis: Cellophane vs LDPE

Cellophane packaging generally incurs higher production costs than LDPE due to its natural cellulose base and more complex manufacturing process. LDPE, derived from polyethylene, offers lower material expenses and greater scalability in industrial packaging applications. Cost analysis reveals LDPE as a more economical choice for high-volume packaging, while cellophane's premium price reflects its biodegradable and aesthetic benefits.

Packaging Applications and Suitability

Cellophane packaging offers superior breathability and biodegradability, making it ideal for fresh produce, bakery items, and confectionery that require moisture control and environmental sustainability. LDPE packaging is highly flexible, moisture-resistant, and durable, suitable for packaging liquids, frozen goods, and heavy-duty applications demanding excellent sealing and puncture resistance. While cellophane excels in eco-friendly and aroma-sensitive uses, LDPE is preferred for robust protection and longer shelf life in industrial and consumer goods packaging.

Printability and Customization Options

Cellophane packaging offers superior printability compared to LDPE packaging due to its smooth, natural cellulose surface that holds inks vividly and crisply. Customization options for cellophane include high-resolution graphics, transparent or tinted finishes, and eco-friendly coatings that enhance visual appeal without compromising biodegradability. In contrast, LDPE packaging typically allows fewer print options, often requiring specialized inks or treatments that may not achieve the same clarity or environmental benefits.

Product Safety and Food Contact Compliance

Cellophane packaging offers superior product safety due to its natural cellulose base, ensuring excellent breathability and moisture resistance that preserves food freshness more effectively than LDPE. Cellophane complies with stringent food contact regulations such as FDA and EU standards, making it ideal for direct food packaging without chemical migration concerns. In contrast, LDPE, while flexible and cost-effective, may leach additives and has lower permeability control, posing potential risks in sensitive food applications.

Market Trends and Consumer Preferences

Cellophane packaging, valued for its biodegradability and transparent appearance, is increasingly favored in markets prioritizing sustainability and eco-friendly products. LDPE packaging continues to dominate due to its cost-effectiveness and flexibility but faces growing consumer demand for more environmentally responsible alternatives. Market trends indicate a steady shift toward cellophane in food and retail sectors, driven by rising consumer awareness around plastic pollution and regulatory pressures on single-use plastics.

Cellophane Packaging vs LDPE Packaging Infographic

materialdif.com

materialdif.com