Cellophane bags offer superior biodegradability and are compostable, making them an eco-friendly choice compared to polyester bags, which are derived from non-renewable petroleum sources and take longer to decompose. Cellophane provides excellent clarity and breathability, enhancing product visibility and freshness, whereas polyester bags excel in durability and resistance to tearing. Choosing between cellophane and polyester bags depends on prioritizing environmental impact or strength and longevity for packaging needs.

Table of Comparison

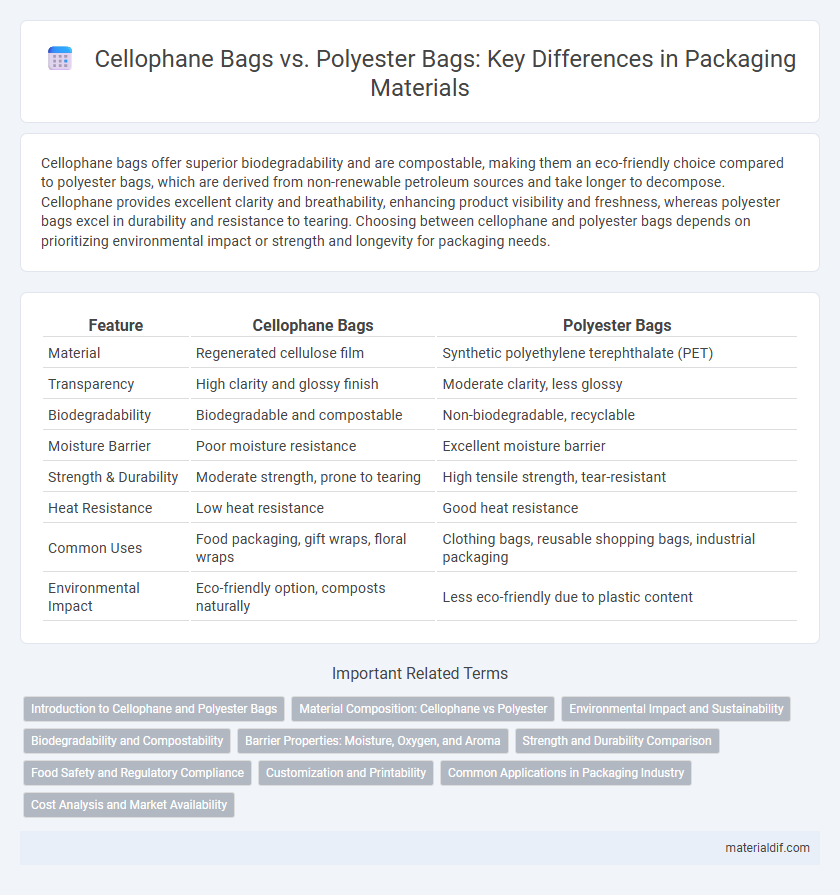

| Feature | Cellophane Bags | Polyester Bags |

|---|---|---|

| Material | Regenerated cellulose film | Synthetic polyethylene terephthalate (PET) |

| Transparency | High clarity and glossy finish | Moderate clarity, less glossy |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Moisture Barrier | Poor moisture resistance | Excellent moisture barrier |

| Strength & Durability | Moderate strength, prone to tearing | High tensile strength, tear-resistant |

| Heat Resistance | Low heat resistance | Good heat resistance |

| Common Uses | Food packaging, gift wraps, floral wraps | Clothing bags, reusable shopping bags, industrial packaging |

| Environmental Impact | Eco-friendly option, composts naturally | Less eco-friendly due to plastic content |

Introduction to Cellophane and Polyester Bags

Cellophane bags are made from regenerated cellulose derived from wood pulp, offering biodegradability, transparency, and moisture resistance ideal for food packaging. Polyester bags, crafted from polyethylene terephthalate (PET), provide superior durability, chemical resistance, and longevity, making them popular for reusable and industrial applications. Both materials serve distinct purposes based on their environmental impact and functional properties in packaging solutions.

Material Composition: Cellophane vs Polyester

Cellophane bags are made from regenerated cellulose, a natural polymer derived from wood pulp, offering biodegradability and compostability. Polyester bags are produced from synthetic polymers such as polyethylene terephthalate (PET), providing higher durability and resistance to moisture. The cellulose composition of cellophane allows for eco-friendly disposal, whereas polyester's plastic base contributes to long-term environmental persistence.

Environmental Impact and Sustainability

Cellophane bags, made from regenerated cellulose derived from wood pulp, are biodegradable and compostable, significantly reducing long-term environmental impact compared to polyester bags, which are petroleum-based and non-biodegradable. Polyester bags contribute to microplastic pollution and take centuries to decompose in landfills, whereas cellophane bags break down naturally within weeks under composting conditions. The sustainable sourcing of raw materials for cellophane production also supports forest management practices, enhancing its eco-friendly profile over synthetic polyester alternatives.

Biodegradability and Compostability

Cellophane bags are made from cellulose derived from wood pulp, making them fully biodegradable and compostable within a few weeks under commercial composting conditions. Polyester bags, composed of synthetic polymers like polyethylene terephthalate (PET), are non-biodegradable and persist in the environment for hundreds of years, contributing to plastic pollution. The compostability of cellophane offers a significant environmental advantage over polyester by reducing landfill waste and promoting sustainable disposal practices.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane bags exhibit superior moisture barrier properties compared to polyester bags, effectively preventing water vapor transmission which is crucial for preserving product freshness. In terms of oxygen permeability, polyester bags generally provide a better oxygen barrier, reducing oxidation and extending shelf life for oxygen-sensitive products. When it comes to aroma retention, cellophane offers moderate protection, while polyester bags typically provide enhanced aroma barrier capabilities, making them suitable for packaging strong-smelling or fragrant items.

Strength and Durability Comparison

Cellophane bags offer moderate strength with excellent clarity but are less durable and prone to tearing compared to polyester bags. Polyester bags provide superior tensile strength, enhanced puncture resistance, and longer-lasting durability, making them suitable for heavy-duty use. The water-resistant and tear-proof nature of polyester bags ensures better performance in demanding storage and packaging applications.

Food Safety and Regulatory Compliance

Cellophane bags, made from regenerated cellulose, offer superior breathability and biodegradability, making them ideal for packaging fresh foods while meeting stringent FDA and EU food safety regulations. Polyester bags, composed of synthetic polymers, provide enhanced durability but lack the natural barrier properties essential for preventing moisture and oxygen transfer, which can compromise food quality. Regulatory compliance favors cellophane in applications requiring non-toxicity and environmental safety, whereas polyester may necessitate additional certifications for food contact materials.

Customization and Printability

Cellophane bags offer superior printability due to their smooth, transparent surface, allowing for high-quality, vibrant custom designs that enhance brand visibility. Polyester bags, while durable and water-resistant, often require specialized inks or processes for printing, which can limit customization options and increase production costs. Businesses seeking detailed, colorful branding typically prefer cellophane bags to maximize visual appeal and customizable features.

Common Applications in Packaging Industry

Cellophane bags are widely used for food packaging due to their excellent moisture barrier and biodegradability, making them ideal for wrapping candies, bakery items, and fresh produce. Polyester bags, favored for their durability, resistance to stretching, and clear, glossy finish, are commonly used in luxury packaging and garment protection. Both materials serve distinct needs in the packaging industry, with cellophane emphasizing eco-friendly disposability and polyester offering high strength and visual appeal.

Cost Analysis and Market Availability

Cellophane bags typically cost 10-20% less than polyester bags due to lower raw material and manufacturing expenses, making them a budget-friendly option for packaging. Market availability of cellophane bags is widespread, with numerous suppliers globally offering various sizes and customization options, while polyester bags, often favored for durability and moisture resistance, have a more niche market and higher price point. Cost-sensitive industries prioritize cellophane bags for their affordability and eco-friendly appeal, whereas premium packaging sectors invest in polyester bags despite the higher cost for enhanced strength and shelf life.

Cellophane Bags vs Polyester Bags Infographic

materialdif.com

materialdif.com