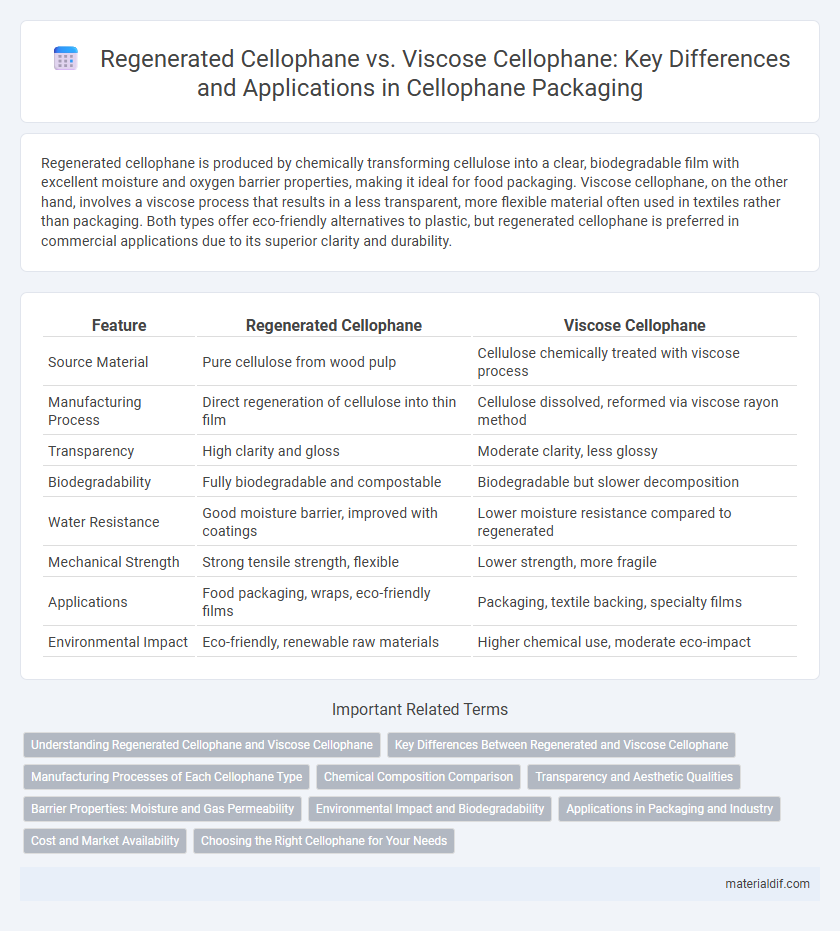

Regenerated cellophane is produced by chemically transforming cellulose into a clear, biodegradable film with excellent moisture and oxygen barrier properties, making it ideal for food packaging. Viscose cellophane, on the other hand, involves a viscose process that results in a less transparent, more flexible material often used in textiles rather than packaging. Both types offer eco-friendly alternatives to plastic, but regenerated cellophane is preferred in commercial applications due to its superior clarity and durability.

Table of Comparison

| Feature | Regenerated Cellophane | Viscose Cellophane |

|---|---|---|

| Source Material | Pure cellulose from wood pulp | Cellulose chemically treated with viscose process |

| Manufacturing Process | Direct regeneration of cellulose into thin film | Cellulose dissolved, reformed via viscose rayon method |

| Transparency | High clarity and gloss | Moderate clarity, less glossy |

| Biodegradability | Fully biodegradable and compostable | Biodegradable but slower decomposition |

| Water Resistance | Good moisture barrier, improved with coatings | Lower moisture resistance compared to regenerated |

| Mechanical Strength | Strong tensile strength, flexible | Lower strength, more fragile |

| Applications | Food packaging, wraps, eco-friendly films | Packaging, textile backing, specialty films |

| Environmental Impact | Eco-friendly, renewable raw materials | Higher chemical use, moderate eco-impact |

Understanding Regenerated Cellophane and Viscose Cellophane

Regenerated cellophane is produced by chemically treating natural cellulose to create a translucent, biodegradable film commonly used for packaging, known for its moisture permeability and eco-friendly properties. Viscose cellophane, a subtype derived from the viscose process, involves dissolving cellulose xanthate to form a fiber or film that offers enhanced flexibility and strength while maintaining biodegradability. Understanding the distinctions between these materials highlights their applications in sustainable packaging, where regenerated cellophane excels in clarity and breathability, and viscose cellophane provides superior mechanical durability.

Key Differences Between Regenerated and Viscose Cellophane

Regenerated cellophane is produced by chemically converting cellulose into a cellulose solution before reforming it into thin films, whereas viscose cellophane is derived through the viscose process, involving dissolving cellulose xanthate to create a cellulose film. Regenerated cellophane typically exhibits higher purity, clarity, and biodegradability compared to viscose cellophane, which may contain residual chemicals altering its properties. Key differences also include variations in tensile strength, moisture permeability, and environmental impact, with regenerated cellophane often favored for eco-friendly packaging applications.

Manufacturing Processes of Each Cellophane Type

Regenerated cellophane is produced by dissolving cellulose in alkali and carbon disulfide to create viscose, which is then extruded through a slit into an acid bath, regenerating the cellulose into thin films. Viscose cellophane shares this initial viscose solution stage but often involves additional washing and bleaching steps to enhance clarity and strength. The differing manufacturing processes result in variations in film properties such as transparency, tensile strength, and environmental impact.

Chemical Composition Comparison

Regenerated cellophane is primarily composed of cellulose treated with sulfuric acid and sodium hydroxide, resulting in a transparent, biodegradable film with minimal chemical additives. Viscose cellophane, derived from cellulose treated with carbon disulfide and sodium hydroxide to form viscose rayon, contains residual chemicals that enhance flexibility but reduce biodegradability. The key chemical difference lies in the viscose process introducing sulfur compounds, whereas regenerated cellophane maintains a purer cellulose structure with fewer chemical modifications.

Transparency and Aesthetic Qualities

Regenerated cellophane offers superior transparency compared to viscose cellophane, making it ideal for applications requiring clear, glossy packaging. The aesthetic qualities of regenerated cellophane include a smooth, high-gloss finish that enhances product visibility and appeal. Viscose cellophane tends to be less transparent and exhibits a slightly matte texture, affecting its clarity and overall visual impact.

Barrier Properties: Moisture and Gas Permeability

Regenerated cellophane exhibits superior moisture barrier properties compared to viscose cellophane, making it more effective in preventing water vapor transmission and preserving product freshness. Viscose cellophane generally shows higher gas permeability, allowing greater oxygen and carbon dioxide exchange, which can affect the shelf life of packaged goods. The enhanced barrier properties of regenerated cellophane are attributed to its more uniform polymer structure and tighter molecular alignment.

Environmental Impact and Biodegradability

Regenerated cellophane, derived from cellulose through environmentally controlled processes, offers superior biodegradability compared to viscose cellophane, which involves more chemical-intensive production impacting ecosystems. The lower carbon footprint and reduced toxic emissions associated with regenerated cellophane make it a more sustainable option within biodegradable packaging materials. Viscose cellophane's manufacturing typically releases harmful byproducts, whereas regenerated variants break down more readily without leaving persistent pollution.

Applications in Packaging and Industry

Regenerated cellophane is widely used in food packaging due to its excellent oxygen and moisture barrier properties, ensuring product freshness and extended shelf life. Viscose cellophane, with its greater strength and flexibility, finds applications in industrial packaging, such as wrapping textiles, gift products, and pharmaceuticals, where durability is essential. Both types are biodegradable and favored in sustainable packaging solutions, meeting increasing environmental regulations in various industries.

Cost and Market Availability

Regenerated cellophane generally has a higher production cost due to its more environmentally friendly processes, limiting its widespread market availability compared to viscose cellophane. Viscose cellophane remains more cost-effective and is extensively available globally, driven by established manufacturing infrastructure. Market demand for sustainable packaging solutions is gradually increasing regenerated cellophane's share despite the price premium.

Choosing the Right Cellophane for Your Needs

Regenerated cellophane, derived from purified cellulose, offers superior clarity and biodegradability compared to viscose cellophane, which contains added chemicals for flexibility but may have reduced environmentally friendly properties. When choosing the right cellophane for packaging or crafting, prioritize regenerated cellophane for eco-friendly applications requiring natural material composition and excellent transparency. Viscose cellophane suits projects demanding greater durability and elasticity but requires careful consideration of its chemical additives and environmental impact.

Regenerated Cellophane vs Viscose Cellophane Infographic

materialdif.com

materialdif.com