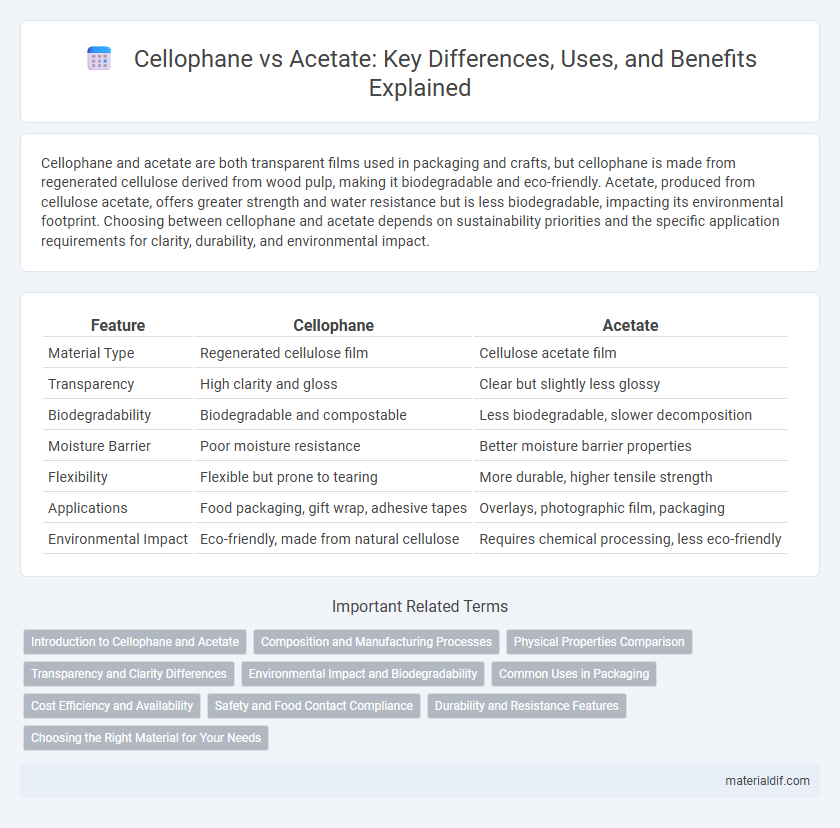

Cellophane and acetate are both transparent films used in packaging and crafts, but cellophane is made from regenerated cellulose derived from wood pulp, making it biodegradable and eco-friendly. Acetate, produced from cellulose acetate, offers greater strength and water resistance but is less biodegradable, impacting its environmental footprint. Choosing between cellophane and acetate depends on sustainability priorities and the specific application requirements for clarity, durability, and environmental impact.

Table of Comparison

| Feature | Cellophane | Acetate |

|---|---|---|

| Material Type | Regenerated cellulose film | Cellulose acetate film |

| Transparency | High clarity and gloss | Clear but slightly less glossy |

| Biodegradability | Biodegradable and compostable | Less biodegradable, slower decomposition |

| Moisture Barrier | Poor moisture resistance | Better moisture barrier properties |

| Flexibility | Flexible but prone to tearing | More durable, higher tensile strength |

| Applications | Food packaging, gift wrap, adhesive tapes | Overlays, photographic film, packaging |

| Environmental Impact | Eco-friendly, made from natural cellulose | Requires chemical processing, less eco-friendly |

Introduction to Cellophane and Acetate

Cellophane is a transparent, biodegradable film made from cellulose, primarily sourced from wood pulp or cotton fibers, widely used for packaging due to its moisture-resistant properties. Acetate, derived from cellulose acetate, is a semi-synthetic film known for its higher tensile strength and better clarity compared to cellophane, commonly utilized in photographic films and decorative applications. Both materials offer unique advantages in sustainability and functionality, with cellophane favored for eco-friendly packaging and acetate for its durability and aesthetic appeal.

Composition and Manufacturing Processes

Cellophane is made from cellulose derived from wood pulp or cotton fibers through a chemical process involving alkali and carbon disulfide, resulting in regenerated cellulose film. Acetate, in contrast, is produced by acetylating cellulose with acetic anhydride, creating cellulose acetate fibers that are then cast into films or fibers. The manufacturing of cellophane emphasizes biodegradability due to its natural cellulose composition, while acetate's acetylation process imparts greater softness and flexibility but reduces its biodegradability.

Physical Properties Comparison

Cellophane is a thin, transparent film made from regenerated cellulose, known for its excellent breathability and biodegradability, whereas acetate is a synthetic cellulose-based film offering superior clarity and heat resistance. Cellophane exhibits lower tensile strength and flexibility compared to acetate, making acetate more suitable for packaging requiring durability and moisture resistance. Both materials differ in water vapor permeability, with cellophane allowing higher permeability, ideal for freshness retention in food packaging.

Transparency and Clarity Differences

Cellophane offers superior clarity and transparency compared to acetate, making it ideal for packaging where product visibility is crucial. While acetate films tend to have a slight haze due to their synthetic composition, cellophane exhibits a natural, glass-like finish that enhances visual appeal. The high transparency of cellophane also allows for better print quality and color vibrancy in packaging applications.

Environmental Impact and Biodegradability

Cellophane, derived from cellulose, is biodegradable and compostable, breaking down naturally in the environment within weeks under proper conditions. Acetate, a synthetic polymer made from cellulose acetate, decomposes more slowly and often requires industrial composting to degrade effectively. The environmental impact of cellophane is lower due to its renewable source and faster biodegradability, making it a more sustainable choice compared to acetate films.

Common Uses in Packaging

Cellophane is widely used for food packaging, offering excellent moisture barrier properties and biodegradability, making it ideal for wrapping fresh produce and baked goods. Acetate, known for its clarity and flexibility, is commonly utilized in packaging for luxury items such as cosmetics and gift wraps where aesthetic appeal is crucial. Both materials serve different market needs within packaging, with cellophane focusing on sustainability and food preservation, while acetate emphasizes visual presentation and durability.

Cost Efficiency and Availability

Cellophane is generally more cost-efficient than acetate due to its lower production expenses and widespread availability from renewable cellulose sources. Unlike acetate, which often requires more complex chemical processing, cellophane is readily produced in large quantities, making it a budget-friendly packaging material. Markets favor cellophane for its balance of affordability and accessibility, particularly in food and retail packaging sectors.

Safety and Food Contact Compliance

Cellophane is biodegradable and generally regarded as safe for food contact, complying with FDA and EU food safety regulations due to its natural cellulose base. Acetate, derived from cellulose acetate, also meets food contact standards but may contain plasticizers that require careful evaluation for migration limits and overall safety. Both materials are used in food packaging, but cellophane's natural origin often provides an advantage in sustainability and safer chemical profiles.

Durability and Resistance Features

Cellophane offers moderate durability with good biodegradability but is prone to tearing and moisture sensitivity. Acetate films demonstrate superior durability and resistance to heat, moisture, and chemicals, making them ideal for more demanding packaging and labeling applications. The enhanced resilience of acetate extends product protection and shelf life compared to cellophane.

Choosing the Right Material for Your Needs

Cellophane, made from regenerated cellulose, offers superior biodegradability and exceptional barrier properties against oils and greases compared to acetate, which is derived from cellulose acetate and is less eco-friendly but more moisture-resistant. For packaging requiring high clarity and environmental sustainability, cellophane is the optimal choice, especially in food wrap and gift packaging. Acetate excels in applications demanding moisture resistance and flexibility, such as photographic film and decorative films, making material selection dependent on balancing environmental impact with functional requirements.

Cellophane vs Acetate Infographic

materialdif.com

materialdif.com