Cellophane PET is derived from natural polymers, making it a more sustainable alternative compared to petrochemical polymers that are synthesized from fossil fuels. Natural polymers like cellulose offer biodegradability and reduced environmental impact, while petrochemical polymers often contribute to pollution and persistent waste. Choosing cellophane PET supports eco-friendly packaging solutions by leveraging renewable resources and minimizing reliance on non-renewable petrochemicals.

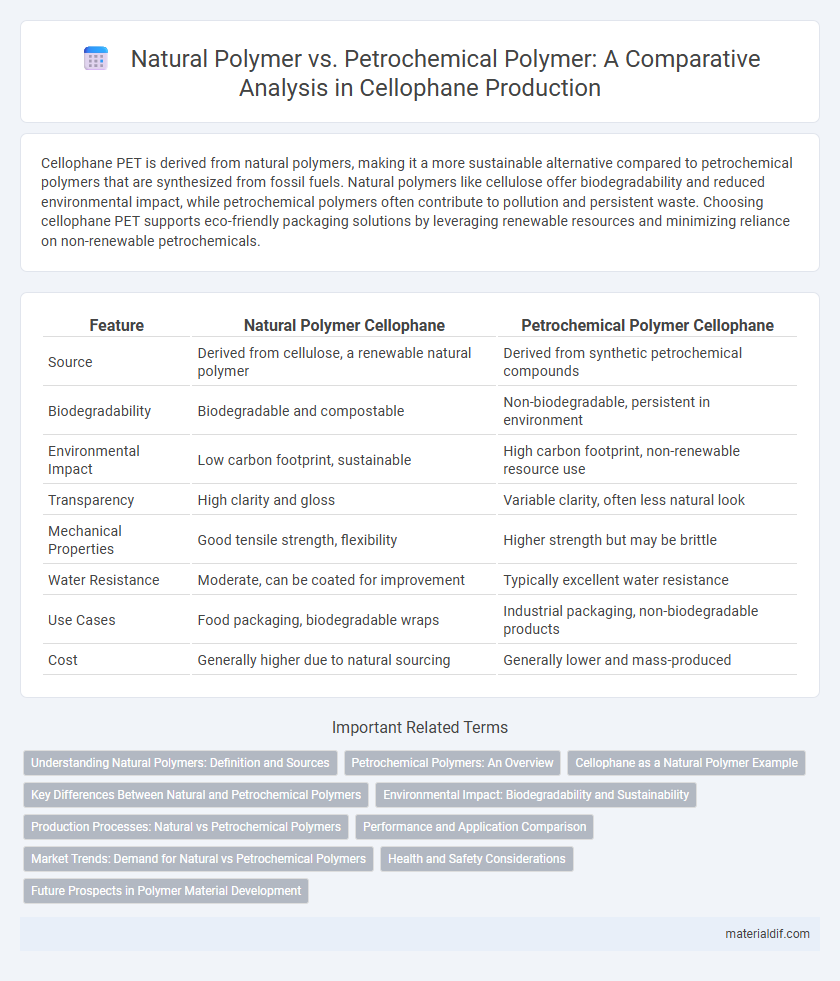

Table of Comparison

| Feature | Natural Polymer Cellophane | Petrochemical Polymer Cellophane |

|---|---|---|

| Source | Derived from cellulose, a renewable natural polymer | Derived from synthetic petrochemical compounds |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, persistent in environment |

| Environmental Impact | Low carbon footprint, sustainable | High carbon footprint, non-renewable resource use |

| Transparency | High clarity and gloss | Variable clarity, often less natural look |

| Mechanical Properties | Good tensile strength, flexibility | Higher strength but may be brittle |

| Water Resistance | Moderate, can be coated for improvement | Typically excellent water resistance |

| Use Cases | Food packaging, biodegradable wraps | Industrial packaging, non-biodegradable products |

| Cost | Generally higher due to natural sourcing | Generally lower and mass-produced |

Understanding Natural Polymers: Definition and Sources

Natural polymers are macromolecules derived from renewable biological sources such as plants, animals, and microorganisms, exhibiting biodegradability and environmental compatibility. Common examples include cellulose from wood and cotton, proteins like silk and collagen, and polysaccharides such as starch and chitosan. Unlike petrochemical polymers synthesized from fossil fuels, natural polymers offer sustainable alternatives with diverse functional properties used in packaging, textiles, and biomedical applications.

Petrochemical Polymers: An Overview

Petrochemical polymers, derived from fossil fuels such as crude oil and natural gas, dominate the plastics industry due to their versatility and cost-effectiveness. These synthetic polymers, including polyethylene, polypropylene, and polystyrene, offer high durability, chemical resistance, and ease of manufacturing at scale. However, their non-biodegradable nature and reliance on finite resources pose significant environmental challenges compared to natural polymers like cellulose-based cellophane.

Cellophane as a Natural Polymer Example

Cellophane is a natural polymer derived from cellulose, making it biodegradable and environmentally friendly compared to petrochemical polymers like polyethylene and polypropylene. Its production involves regenerating cellulose from wood pulp, which results in a transparent, flexible film widely used for packaging applications. Unlike synthetic polymers, cellophane decomposes naturally, reducing plastic pollution and offering a sustainable alternative in the packaging industry.

Key Differences Between Natural and Petrochemical Polymers

Natural polymers like cellophane are derived from renewable resources such as cellulose, offering biodegradability and environmental sustainability. Petrochemical polymers, synthesized from fossil fuels, provide greater versatility and durability but lack biodegradability, leading to environmental pollution. Key differences include origin, environmental impact, and decomposition rates, with natural polymers favoring eco-friendly applications while petrochemical polymers excel in industrial versatility.

Environmental Impact: Biodegradability and Sustainability

Cellophane, derived from natural polymers like cellulose, offers significant environmental advantages over petrochemical polymers due to its biodegradability and renewable sourcing. Unlike conventional plastics made from fossil fuels, cellophane decomposes efficiently in natural environments, reducing landfill accumulation and microplastic pollution. This sustainable profile supports circular economy goals by utilizing biodegradable raw materials that lower carbon footprints and dependence on non-renewable resources.

Production Processes: Natural vs Petrochemical Polymers

Natural polymers like cellophane derive from renewable cellulose sources such as wood pulp, undergoing processes like controlled hydrolysis and regeneration to form films. Petrochemical polymers, by contrast, rely on fossil fuels and involve polymerization techniques such as addition or condensation polymerization under high pressure and temperature. The production of natural polymers emphasizes biodegradability and sustainability, whereas petrochemical polymer production prioritizes scalability and cost-efficiency.

Performance and Application Comparison

Natural polymers like cellulose-based cellophane offer superior biodegradability and breathability compared to petrochemical polymers such as polyethylene and polypropylene. Cellophane's excellent oxygen and moisture barrier properties make it ideal for food packaging applications where freshness and quality preservation are critical. Petrochemical polymers excel in flexibility and cost-efficiency but often fall short in environmental sustainability and compostability, limiting their use in eco-friendly products.

Market Trends: Demand for Natural vs Petrochemical Polymers

Market trends indicate a growing consumer preference for natural polymers such as cellophane, driven by increased environmental awareness and demand for sustainable packaging solutions. Petrochemical polymers, while still dominating due to lower costs and established supply chains, face regulatory pressures and shifting market dynamics favoring biodegradable alternatives. The global natural polymer market is projected to grow at a compound annual growth rate (CAGR) of over 7%, outpacing petrochemical polymer growth rates in key regions focused on eco-friendly product development.

Health and Safety Considerations

Cellophane, derived from natural cellulose, offers significant health and safety advantages over petrochemical polymers due to its biodegradability and non-toxic nature, reducing environmental and human exposure to harmful chemicals. Natural polymers like cellophane do not release VOCs (volatile organic compounds) during degradation, unlike many petrochemical-based plastics that can emit hazardous substances impacting respiratory health. The sustainable sourcing and compostability of cellophane further minimize long-term ecological risks associated with petrochemical polymer waste accumulation.

Future Prospects in Polymer Material Development

Natural polymers like cellophane, derived from renewable cellulose sources, offer significant sustainability advantages over petrochemical polymers, which rely on finite fossil fuels. Future prospects in polymer material development emphasize enhancing the biodegradability and mechanical properties of cellophane to meet increasing environmental regulations and consumer demand for eco-friendly packaging. Advanced research on cellulose modification and green manufacturing processes aims to position natural polymers as competitive alternatives in a market dominated by petrochemical-based plastics.

Natural Polymer vs Petrochemical Polymer Infographic

materialdif.com

materialdif.com