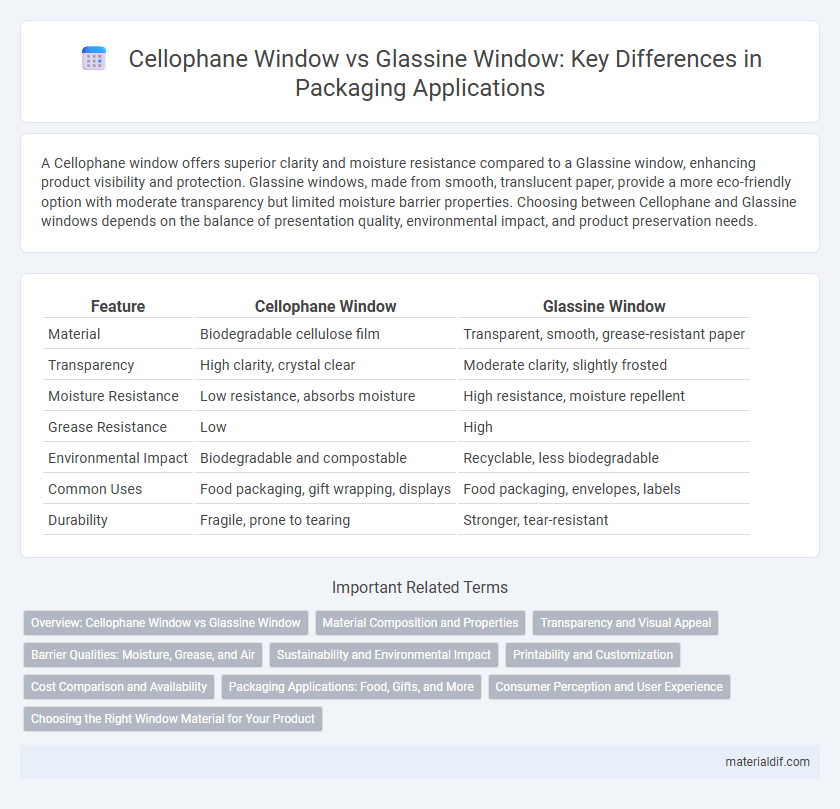

A Cellophane window offers superior clarity and moisture resistance compared to a Glassine window, enhancing product visibility and protection. Glassine windows, made from smooth, translucent paper, provide a more eco-friendly option with moderate transparency but limited moisture barrier properties. Choosing between Cellophane and Glassine windows depends on the balance of presentation quality, environmental impact, and product preservation needs.

Table of Comparison

| Feature | Cellophane Window | Glassine Window |

|---|---|---|

| Material | Biodegradable cellulose film | Transparent, smooth, grease-resistant paper |

| Transparency | High clarity, crystal clear | Moderate clarity, slightly frosted |

| Moisture Resistance | Low resistance, absorbs moisture | High resistance, moisture repellent |

| Grease Resistance | Low | High |

| Environmental Impact | Biodegradable and compostable | Recyclable, less biodegradable |

| Common Uses | Food packaging, gift wrapping, displays | Food packaging, envelopes, labels |

| Durability | Fragile, prone to tearing | Stronger, tear-resistant |

Overview: Cellophane Window vs Glassine Window

Cellophane windows offer superior clarity, moisture resistance, and biodegradability compared to glassine windows, which are coated paper known for their smooth, translucent surface and grease resistance. While cellophane provides a glossy, transparent finish ideal for showcasing product visibility, glassine windows excel in durability and preventing moisture and grease penetration, making them suitable for packaging baked goods and oily items. Choosing between cellophane and glassine windows depends on the desired balance of transparency, environmental impact, and barrier properties for specific packaging applications.

Material Composition and Properties

Cellophane windows are made from regenerated cellulose, offering high transparency, biodegradability, and breathability, which enhances moisture and aroma control in packaging. Glassine windows consist of supercalendered, highly compressed paper that provides a smooth, glossy finish with excellent grease resistance but lower transparency compared to cellophane. The distinct material compositions result in cellophane windows being preferred for see-through packaging with environmental benefits, while glassine windows are favored for oil resistance and a matte, paper-like appearance.

Transparency and Visual Appeal

Cellophane windows offer superior transparency with a clear, glossy finish that enhances the visual appeal of product packaging by providing a crisp, clean view of the contents. Glassine windows, while translucent and smooth, present a frosted appearance that diffuses light, resulting in a softer, muted view that can add a subtle, elegant touch but reduces direct visibility. The choice between cellophane and glassine windows depends on whether sharp clarity or a more understated visual effect aligns better with branding and product presentation goals.

Barrier Qualities: Moisture, Grease, and Air

Cellophane windows offer moderate moisture and grease resistance but provide limited air barrier qualities, making them suitable for packaging that requires basic protection. Glassine windows excel in moisture resistance and provide a stronger grease barrier due to their dense, smooth surface, enhancing durability in oily or wet environments. For airtight packaging, glassine outperforms cellophane by creating a more effective seal against air infiltration, thus extending the shelf life of sensitive products.

Sustainability and Environmental Impact

Cellophane windows are compostable and biodegradable, making them a more sustainable choice compared to glassine windows, which are typically coated with polyethylene and less eco-friendly. Cellophane's natural cellulose composition reduces reliance on plastics and lowers carbon footprint during production and disposal. Brands aiming to minimize environmental impact prefer cellophane windows for packaging, supporting circular economy practices and reducing landfill waste.

Printability and Customization

Cellophane windows offer superior printability due to their smooth, clear surface that enhances ink adhesion and vibrant color reproduction, making them ideal for detailed logos and intricate designs. Glassine windows, while providing a glossy finish and moisture resistance, typically exhibit limited printability, resulting in less vivid and sharp images. Customization options are more extensive with cellophane, allowing for various thicknesses, finishes, and sizes tailored to specific branding needs compared to the more standardized glassine window offerings.

Cost Comparison and Availability

Cellophane windows typically offer a more cost-effective solution compared to glassine windows, making them a preferred choice for budget-conscious packaging projects. Cellophane's widespread production ensures higher availability and quicker supply chains in various markets. Glassine windows, while providing superior grease resistance and clarity, often come at a higher price point and may have limited availability depending on regional suppliers.

Packaging Applications: Food, Gifts, and More

Cellophane windows offer biodegradable, breathable packaging ideal for fresh food items and gift wrapping, enhancing product visibility while maintaining moisture balance. Glassine windows provide a smooth, grease-resistant barrier suited for packaging oily or delicate products, ensuring cleanliness and durability in food and gift packaging. Both materials serve specialized needs in packaging, with cellophane favored for sustainability and glassine chosen for protective qualities in diverse applications.

Consumer Perception and User Experience

Cellophane windows offer consumers a natural, biodegradable option that enhances brand sustainability and transparency, improving eco-friendly product appeal. Glassine windows provide superior grease resistance and clarity, contributing to a premium, clean aesthetic that boosts user confidence in product freshness. Consumer perception favors cellophane for environmental responsibility, while user experience benefits from glassine's durability and moisture resistance in packaging.

Choosing the Right Window Material for Your Product

Cellophane windows offer superior clarity and biodegradability, making them ideal for eco-friendly packaging solutions requiring excellent visual appeal. Glassine windows provide a smooth, translucent barrier with moisture resistance, suitable for products needing protection without full transparency. Selecting the right window material depends on product visibility needs and environmental considerations, with cellophane enhancing display clarity and glassine offering subtle concealment and durability.

Cellophane Window vs Glassine Window Infographic

materialdif.com

materialdif.com