Uncoated cellophane offers a natural, biodegradable option with excellent breathability, making it ideal for packaging fresh produce and bakery items. Coated cellophane features a thin layer of plastic or wax that enhances moisture resistance and durability, suitable for items requiring extended shelf life or protection from external elements. Choosing between uncoated and coated cellophane depends on the specific packaging needs, balancing environmental impact with product preservation.

Table of Comparison

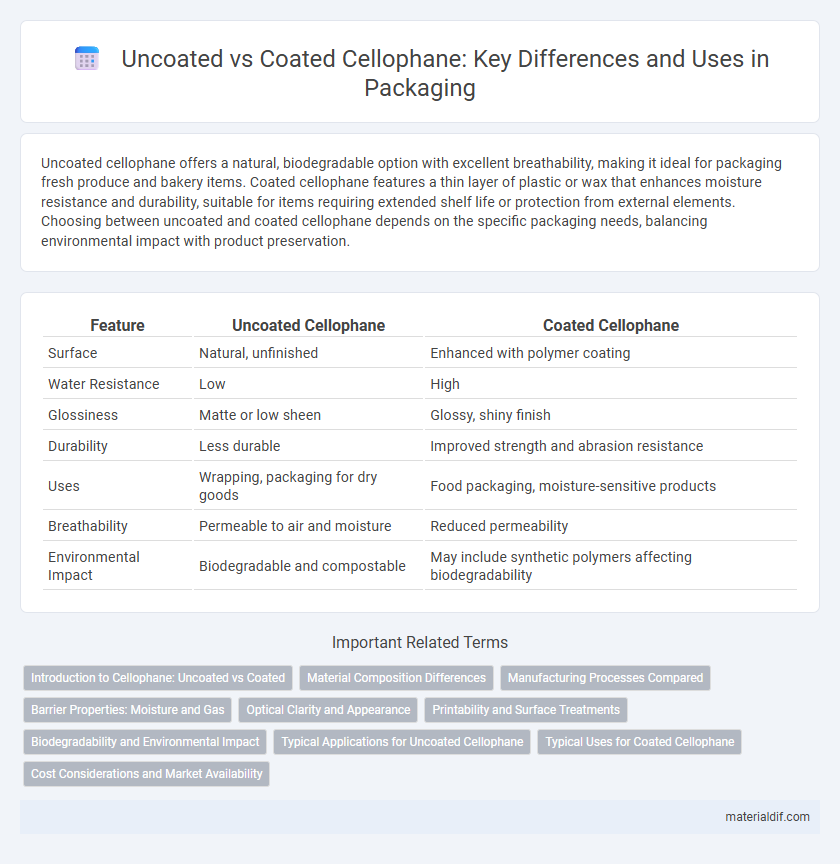

| Feature | Uncoated Cellophane | Coated Cellophane |

|---|---|---|

| Surface | Natural, unfinished | Enhanced with polymer coating |

| Water Resistance | Low | High |

| Glossiness | Matte or low sheen | Glossy, shiny finish |

| Durability | Less durable | Improved strength and abrasion resistance |

| Uses | Wrapping, packaging for dry goods | Food packaging, moisture-sensitive products |

| Breathability | Permeable to air and moisture | Reduced permeability |

| Environmental Impact | Biodegradable and compostable | May include synthetic polymers affecting biodegradability |

Introduction to Cellophane: Uncoated vs Coated

Uncoated cellophane consists of pure cellulose film known for its natural transparency, breathability, and biodegradability, making it ideal for packaging fresh produce and flowers. Coated cellophane features an additional layer of wax or lacquer, enhancing moisture resistance, durability, and printing capabilities, which suits applications requiring extended shelf life or decorative packaging. Understanding the differences in barrier properties and surface treatments helps manufacturers select the appropriate cellophane type for specific product protection and presentation needs.

Material Composition Differences

Uncoated cellophane consists primarily of regenerated cellulose, retaining its natural hydrophilic properties, which allows it to absorb moisture and degrade more easily. Coated cellophane is treated with a thin layer of chemical substances such as nitrocellulose or polyester, enhancing water resistance, durability, and barrier properties. The coated version's material composition modifies its surface energy, making it less permeable to gases and moisture compared to the uncoated form.

Manufacturing Processes Compared

Uncoated cellophane undergoes a straightforward manufacturing process involving the regeneration of cellulose into thin transparent films without additional surface treatments, resulting in a highly biodegradable and breathable material. Coated cellophane includes an extra step where the film surface is treated with a thin polymer layer or wax to enhance moisture resistance, strength, and barrier properties while slightly reducing biodegradability. These manufacturing differences influence the final applications of cellophane, with uncoated films favored for natural breathability and coated versions preferred for improved durability and protective packaging.

Barrier Properties: Moisture and Gas

Uncoated cellophane exhibits moderate moisture barrier properties but is highly permeable to gases such as oxygen and carbon dioxide, limiting its protective capabilities. Coated cellophane enhances barrier performance significantly by applying coatings like nitrocellulose or cellulose acetate, which reduce moisture vapor transmission rate (MVTR) and improve gas impermeability. These coatings make coated cellophane suitable for packaging applications requiring extended shelf life and protection against moisture and gas infiltration.

Optical Clarity and Appearance

Uncoated cellophane offers higher optical clarity with a natural, glossy finish that enhances transparency and brightness, making it ideal for premium packaging requiring clear product visibility. Coated cellophane, treated with a thin polymer layer, improves moisture resistance and durability but slightly reduces optical clarity by introducing a subtle matte or satin effect. The choice between uncoated and coated cellophane depends on the balance needed between appearance quality and functional protection in packaging applications.

Printability and Surface Treatments

Uncoated cellophane offers a natural, porous surface that can absorb inks well but often results in lower print clarity and limited color vibrancy. Coated cellophane undergoes surface treatments such as polyethylene or nitrocellulose coatings that enhance ink adhesion, improve gloss, and enable sharper, more vivid prints. These coatings also provide additional barrier properties, which protect printed graphics and extend durability in packaging applications.

Biodegradability and Environmental Impact

Uncoated cellophane exhibits superior biodegradability due to its natural cellulose composition, breaking down efficiently in composting environments without leaving toxic residues. Coated cellophane, often treated with synthetic polymers or plastic coatings, significantly reduces degradability and increases environmental impact by contributing to microplastic pollution. Choosing uncoated cellophane supports sustainable packaging by minimizing landfill accumulation and facilitating natural decomposition.

Typical Applications for Uncoated Cellophane

Uncoated cellophane is commonly used in food packaging due to its breathability, which helps maintain product freshness and prevents moisture buildup, ideal for wrapping fresh produce, bakery items, and confectionery. Its biodegradable nature makes it a preferred choice for eco-friendly packaging solutions in the pharmaceutical and gift wrap industries. Uncoated cellophane's permeability to air and water vapor supports applications requiring ventilation, such as packaging in floristry and certain agricultural products.

Typical Uses for Coated Cellophane

Coated cellophane is primarily used in packaging applications that require moisture resistance and enhanced durability, such as food wraps, candy packaging, and pharmaceutical products. Its protective coating helps preserve freshness and extend shelf life by preventing moisture and oxygen penetration. The coated surface also allows for easy printing and improved heat-sealing properties, making it ideal for commercial packaging solutions.

Cost Considerations and Market Availability

Uncoated cellophane is generally more affordable due to its simpler manufacturing process, appealing to cost-sensitive packaging markets. Coated cellophane, enhanced with moisture or heat-resistant layers, incurs higher production costs but offers improved durability and functionality, targeting premium product applications. Market availability favors uncoated variants in bulk commodity packaging, while coated cellophane is more niche, supplied primarily by specialized manufacturers catering to specific industrial demands.

Uncoated Cellophane vs Coated Cellophane Infographic

materialdif.com

materialdif.com