Cellophane offers a biodegradable and eco-friendly alternative to polypropylene, making it ideal for sustainable packaging solutions. Unlike polypropylene, which is derived from petroleum and contributes to plastic pollution, cellophane is made from cellulose, ensuring better compostability and reduced environmental impact. The transparency and moisture barrier properties of cellophane closely match those of polypropylene, providing effective protection for packaged goods while supporting greener choices.

Table of Comparison

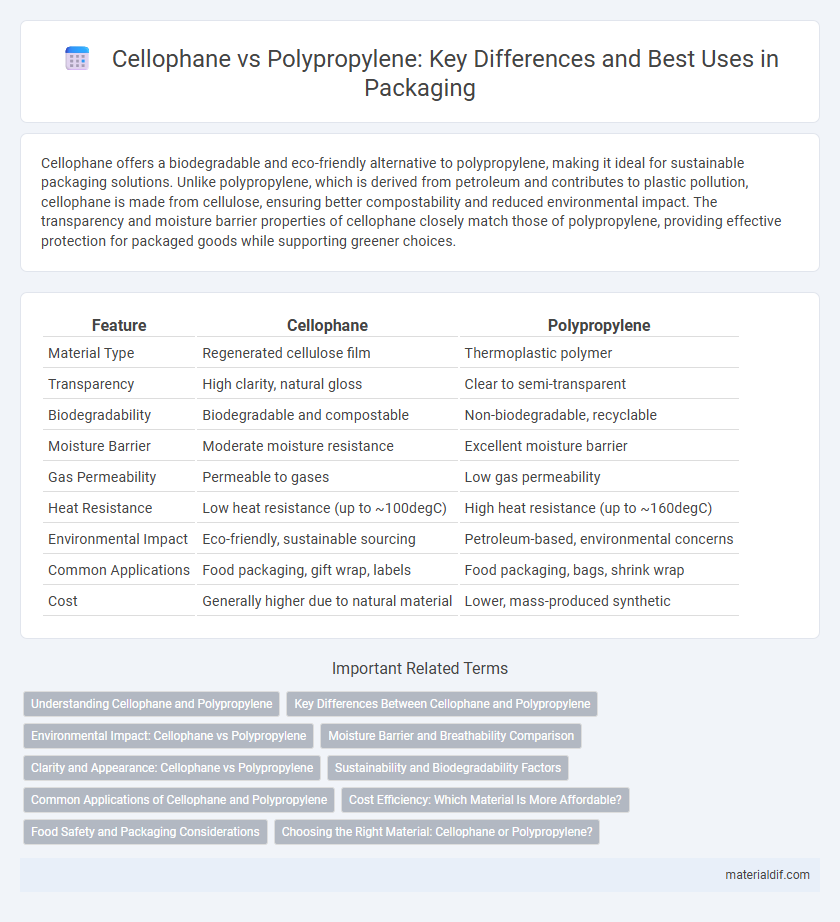

| Feature | Cellophane | Polypropylene |

|---|---|---|

| Material Type | Regenerated cellulose film | Thermoplastic polymer |

| Transparency | High clarity, natural gloss | Clear to semi-transparent |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Moisture Barrier | Moderate moisture resistance | Excellent moisture barrier |

| Gas Permeability | Permeable to gases | Low gas permeability |

| Heat Resistance | Low heat resistance (up to ~100degC) | High heat resistance (up to ~160degC) |

| Environmental Impact | Eco-friendly, sustainable sourcing | Petroleum-based, environmental concerns |

| Common Applications | Food packaging, gift wrap, labels | Food packaging, bags, shrink wrap |

| Cost | Generally higher due to natural material | Lower, mass-produced synthetic |

Understanding Cellophane and Polypropylene

Cellophane is a biodegradable film made from regenerated cellulose, offering excellent breathability and moisture resistance, making it ideal for food packaging that requires freshness preservation. Polypropylene is a synthetic polymer known for its durability, chemical resistance, and moisture barrier properties, frequently used in packaging applications where strength and longevity are critical. Understanding the differences between cellophane and polypropylene helps determine suitable packaging based on environmental impact, transparency, and functional performance.

Key Differences Between Cellophane and Polypropylene

Cellophane is a biodegradable film derived from cellulose, offering excellent breathability and moisture absorption, while polypropylene is a synthetic polymer known for its superior strength, flexibility, and resistance to moisture and chemicals. Cellophane's natural transparency and eco-friendly properties make it ideal for packaging perishable goods, whereas polypropylene provides enhanced durability and is widely used for long-term packaging solutions. The key differences center on biodegradability, moisture barrier capabilities, and environmental impact, with cellophane favored for sustainability and polypropylene preferred for robustness.

Environmental Impact: Cellophane vs Polypropylene

Cellophane is biodegradable and compostable, breaking down naturally within weeks, which significantly reduces environmental pollution compared to polypropylene, a petroleum-based plastic that can persist in landfills for centuries. The production of cellophane relies on renewable cellulose sources such as wood pulp, resulting in a lower carbon footprint and reduced reliance on fossil fuels, unlike polypropylene manufacturing which emits higher levels of greenhouse gases. Disposal and recycling processes for polypropylene pose environmental challenges due to its resistance to natural degradation, whereas cellophane's eco-friendly properties make it a sustainable alternative in packaging applications.

Moisture Barrier and Breathability Comparison

Cellophane offers excellent breathability due to its natural cellulose structure, allowing moisture vapor to pass through while maintaining a moderate moisture barrier. Polypropylene provides a superior moisture barrier with low permeability to water vapor, effectively protecting contents from moisture but limiting breathability. This makes cellophane ideal for packaging items requiring freshness and moisture regulation, whereas polypropylene suits applications needing robust moisture protection.

Clarity and Appearance: Cellophane vs Polypropylene

Cellophane offers superior clarity and a natural, glass-like appearance compared to polypropylene, making it ideal for packaging where product visibility is crucial. Polypropylene tends to have a slightly hazier look with less sharpness in transparency, which can affect the overall presentation quality. The enhanced optical properties of cellophane also reduce glare and provide a smoother surface finish, enhancing the visual appeal of packaged goods.

Sustainability and Biodegradability Factors

Cellophane, derived from cellulose, is a biodegradable and compostable packaging material that breaks down naturally in the environment within weeks to months. Polypropylene, a petroleum-based plastic, poses significant sustainability challenges due to its persistent nature and slow degradation rate, often taking hundreds of years to decompose. Choosing cellophane over polypropylene reduces plastic pollution and supports circular economy goals by enabling easier recycling and lower carbon footprint.

Common Applications of Cellophane and Polypropylene

Cellophane is widely used for food packaging, including bakery items, confectionery, and fresh produce due to its excellent moisture and aroma barrier properties. Polypropylene finds common applications in packaging for snacks, pharmaceuticals, and textiles because of its high durability, chemical resistance, and clarity. Both materials serve distinct purposes based on their barrier performance and flexibility in consumer product packaging.

Cost Efficiency: Which Material Is More Affordable?

Cellophane generally offers lower production costs due to its simpler manufacturing process and use of renewable raw materials compared to polypropylene, which involves petroleum-based inputs and more energy-intensive processing. Despite its higher initial cost, polypropylene provides durability and moisture resistance that can reduce overall packaging waste and ancillary expenses. Evaluating cost efficiency depends on specific application needs, with cellophane favored for budget-conscious projects emphasizing biodegradability.

Food Safety and Packaging Considerations

Cellophane offers superior breathability and biodegradability, making it ideal for packaging fresh produce and perishable foods by reducing moisture buildup and preserving freshness without harmful chemicals. Polypropylene provides excellent moisture barrier properties and higher heat resistance, supporting extended shelf life and suitability for hot-fill processes, but its non-biodegradable nature raises environmental concerns. Food safety standards favor cellophane for natural packaging due to its low chemical migration, while polypropylene is preferred where moisture impermeability and durability under thermal stress are critical.

Choosing the Right Material: Cellophane or Polypropylene?

Cellophane offers superior biodegradability and excellent moisture and aroma barrier properties, making it ideal for eco-friendly packaging solutions. Polypropylene excels in durability, chemical resistance, and heat sealing capabilities, suitable for flexible packaging requiring toughness and clarity. Choosing between cellophane and polypropylene depends on prioritizing environmental impact versus mechanical performance and cost efficiency in packaging applications.

Cellophane vs Polypropylene Infographic

materialdif.com

materialdif.com