Cellophane and acetate films differ primarily in their chemical composition, with cellophane being made from cellulose and acetate film derived from cellulose acetate. Cellophane offers excellent moisture resistance and biodegradability, making it environmentally friendly, while acetate film provides superior clarity and durability, ideal for more demanding packaging applications. The choice between cellophane and acetate film depends on whether sustainability or performance is the priority in a packaging solution.

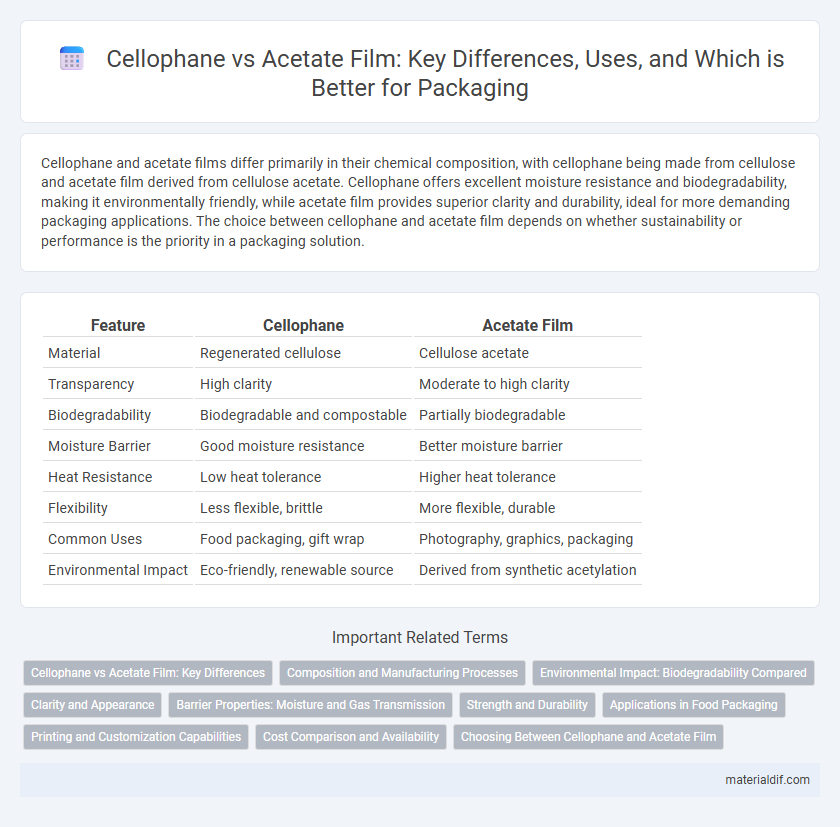

Table of Comparison

| Feature | Cellophane | Acetate Film |

|---|---|---|

| Material | Regenerated cellulose | Cellulose acetate |

| Transparency | High clarity | Moderate to high clarity |

| Biodegradability | Biodegradable and compostable | Partially biodegradable |

| Moisture Barrier | Good moisture resistance | Better moisture barrier |

| Heat Resistance | Low heat tolerance | Higher heat tolerance |

| Flexibility | Less flexible, brittle | More flexible, durable |

| Common Uses | Food packaging, gift wrap | Photography, graphics, packaging |

| Environmental Impact | Eco-friendly, renewable source | Derived from synthetic acetylation |

Cellophane vs Acetate Film: Key Differences

Cellophane is a biodegradable film made from cellulose, offering high transparency and excellent moisture resistance, whereas acetate film is produced from cellulose acetate, known for superior clarity and flexibility but less water resistance. Cellophane's natural origin makes it environmentally friendly, while acetate film often requires chemical plasticizers. In packaging, cellophane is preferred for eco-conscious applications, whereas acetate film is commonly used in photographic and decorative purposes due to its clarity and strength.

Composition and Manufacturing Processes

Cellophane is made from regenerated cellulose derived from wood pulp or cotton fibers, involving a process of dissolving cellulose in alkali and carbon disulfide to produce viscose, which is then spun into a thin film. Acetate film is composed primarily of cellulose acetate, created by acetylating cellulose fibers with acetic anhydride and sulfuric acid, followed by solvent casting or extrusion to form the film. The manufacturing of cellophane emphasizes biodegradability due to its natural cellulose base, whereas acetate film manufacturing focuses on producing a more durable, moisture-resistant material through chemical modification of cellulose.

Environmental Impact: Biodegradability Compared

Cellophane, derived from cellulose, is fully biodegradable and compostable, breaking down naturally within weeks in the environment. In contrast, acetate film, though partially biodegradable, contains plasticizers that slow decomposition and contribute to microplastic pollution. Choosing cellophane over acetate film significantly reduces environmental impact by minimizing long-term waste and promoting sustainable packaging solutions.

Clarity and Appearance

Cellophane offers exceptional clarity with a natural gloss that enhances product visibility, making it ideal for retail packaging where transparency is crucial. Acetate film, while also clear, provides a smoother and more uniform surface, resulting in a slightly higher sheen and a polished appearance. The choice between cellophane and acetate hinges on the desired level of transparency and the specific visual impact needed for the packaged item.

Barrier Properties: Moisture and Gas Transmission

Cellophane exhibits low moisture vapor transmission rates due to its dense cellulose structure, making it an effective moisture barrier in packaging applications. In contrast, acetate film typically allows higher gas permeability, offering less resistance to oxygen transmission compared to cellophane. This difference in barrier properties makes cellophane more suitable for preserving product freshness by limiting moisture and gas exchange.

Strength and Durability

Cellophane exhibits moderate strength and limited durability due to its natural cellulose composition, making it prone to tearing and moisture sensitivity. Acetate film, derived from cellulose acetate, offers significantly higher tensile strength and improved resistance to moisture and chemicals, enhancing its durability for packaging and photographic applications. The superior durability of acetate film makes it preferable in environments requiring prolonged exposure to humidity and mechanical stress.

Applications in Food Packaging

Cellophane offers superior oxygen and moisture barrier properties compared to acetate film, making it ideal for preserving freshness in food packaging such as candy wrappers, snack bags, and bakery covers. Its biodegradable nature enhances sustainability credentials, aligning with increasing demand for eco-friendly packaging solutions. Acetate film, while less effective as a barrier, is favored in applications requiring greater clarity and glossy appearance, often used for decorative wrapping or labels.

Printing and Customization Capabilities

Cellophane offers limited printing options due to its natural cellulose composition, resulting in lower ink adhesion and reduced color vibrancy compared to acetate film. Acetate film provides superior customization capabilities, supporting high-resolution printing and a wider range of ink types, making it ideal for detailed graphics and vibrant designs. For applications requiring intricate printing and vivid colors, acetate film significantly outperforms cellophane in both quality and versatility.

Cost Comparison and Availability

Cellophane typically costs less than acetate film due to its simpler manufacturing process and widespread availability as a biodegradable packaging material. Acetate film, often used for higher-end applications like photography or archival storage, commands a higher price because of its superior durability and chemical stability. Availability of cellophane is generally broader in retail and industrial markets, whereas acetate film is more niche and less frequently stocked.

Choosing Between Cellophane and Acetate Film

Cellophane offers superior breathability and biodegradability, making it ideal for environmentally conscious packaging solutions, while acetate film provides greater clarity and moisture resistance, preferred in applications requiring durability and higher visual appeal. Choosing between cellophane and acetate film depends on prioritizing either eco-friendliness with natural cellulose composition or enhanced physical properties afforded by cellulose acetate. Industries such as food packaging favor cellophane for compostability, whereas photographic and decorative uses benefit from the robust and transparent qualities of acetate film.

Cellophane vs Acetate Film Infographic

materialdif.com

materialdif.com