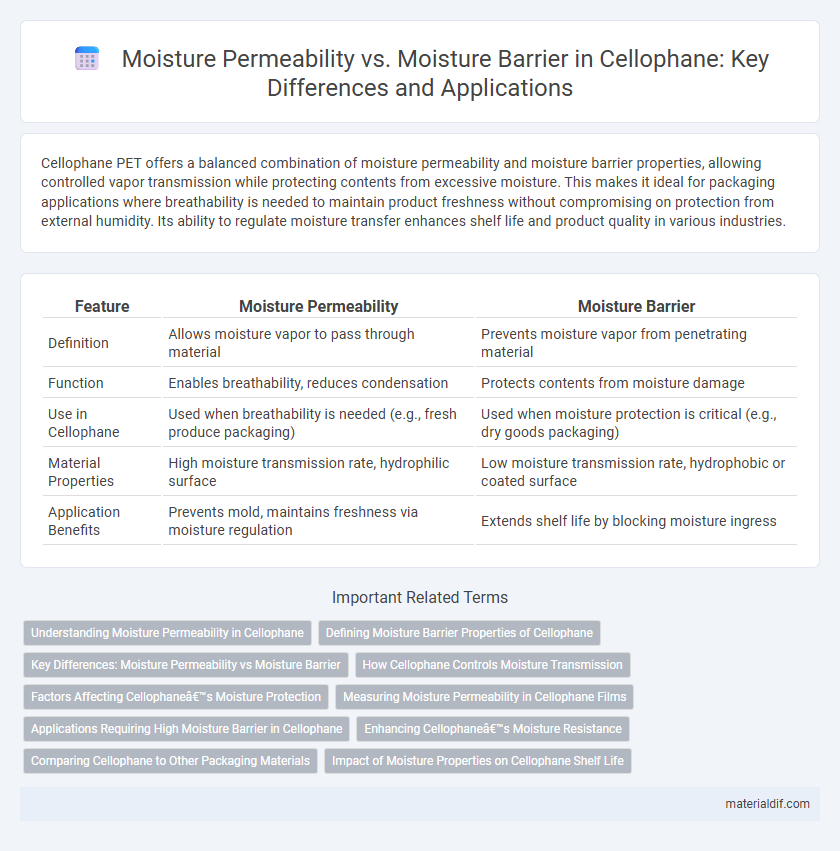

Cellophane PET offers a balanced combination of moisture permeability and moisture barrier properties, allowing controlled vapor transmission while protecting contents from excessive moisture. This makes it ideal for packaging applications where breathability is needed to maintain product freshness without compromising on protection from external humidity. Its ability to regulate moisture transfer enhances shelf life and product quality in various industries.

Table of Comparison

| Feature | Moisture Permeability | Moisture Barrier |

|---|---|---|

| Definition | Allows moisture vapor to pass through material | Prevents moisture vapor from penetrating material |

| Function | Enables breathability, reduces condensation | Protects contents from moisture damage |

| Use in Cellophane | Used when breathability is needed (e.g., fresh produce packaging) | Used when moisture protection is critical (e.g., dry goods packaging) |

| Material Properties | High moisture transmission rate, hydrophilic surface | Low moisture transmission rate, hydrophobic or coated surface |

| Application Benefits | Prevents mold, maintains freshness via moisture regulation | Extends shelf life by blocking moisture ingress |

Understanding Moisture Permeability in Cellophane

Moisture permeability in cellophane refers to the material's ability to allow water vapor to pass through its structure, which is critical for applications requiring breathability. Unlike moisture barriers that block vapor transmission, cellophane's semi-permeable nature helps regulate moisture levels, preventing condensation and maintaining product freshness. Understanding the permeability rate, often measured in grams per square meter per day (g/m2/day), enables manufacturers to tailor cellophane films for specific packaging needs where balanced moisture control is essential.

Defining Moisture Barrier Properties of Cellophane

Cellophane's moisture barrier properties are defined by its ability to selectively restrict water vapor transmission while allowing minimal permeability. This moisture resistance is achieved through the dense, crystalline structure of regenerated cellulose in cellophane, which significantly reduces moisture penetration. Controlling moisture barrier characteristics is essential for applications requiring protection against humidity and preserving product quality.

Key Differences: Moisture Permeability vs Moisture Barrier

Moisture permeability refers to the ability of cellophane to allow water vapor to pass through its structure, making it semi-permeable and suitable for packaging items that require breathability. In contrast, a moisture barrier is a material characteristic that prevents water vapor from penetrating, effectively protecting contents from moisture damage and extending shelf life. The key difference lies in permeability enabling controlled moisture exchange, while a moisture barrier ensures complete moisture resistance.

How Cellophane Controls Moisture Transmission

Cellophane controls moisture transmission through its semi-permeable structure, allowing limited moisture permeability that helps maintain product freshness while preventing excessive moisture buildup. Unlike impermeable moisture barriers, cellophane permits a controlled exchange of water vapor, balancing breathability with protection. This unique characteristic makes cellophane an ideal packaging material for items requiring moisture regulation, such as food and pharmaceuticals.

Factors Affecting Cellophane’s Moisture Protection

Cellophane's moisture protection depends on factors such as thickness, surface coatings, and environmental humidity levels, which directly influence its moisture permeability and barrier properties. Thicker films and specialized coatings like wax or nitrocellulose significantly reduce water vapor transmission rates, enhancing cellophane's effectiveness as a moisture barrier. Temperature fluctuations and exposure to oils or chemicals can also alter the film's structure, impacting its ability to maintain consistent moisture resistance over time.

Measuring Moisture Permeability in Cellophane Films

Moisture permeability in cellophane films is measured using standardized tests such as the ASTM E96, which quantifies the rate of water vapor transmission through the film under controlled humidity and temperature conditions. The water vapor transmission rate (WVTR) is a critical parameter reflecting the film's ability to allow moisture to pass, directly impacting its effectiveness as a moisture barrier. Precise measurement of WVTR enables manufacturers to optimize cellophane for applications requiring specific moisture control, balancing permeability with protection against moisture ingress.

Applications Requiring High Moisture Barrier in Cellophane

Cellophane offers varying degrees of moisture permeability, with specialized formulations designed for applications requiring high moisture barrier properties, such as food packaging for products like confectionery and dried fruits. Its ability to prevent moisture ingress helps maintain product freshness and extends shelf life by reducing microbial growth and spoilage. High moisture barrier cellophane variants often incorporate coatings or lamination with materials like nitrocellulose or PVDC to enhance performance in moisture-sensitive applications.

Enhancing Cellophane’s Moisture Resistance

Cellophane's moisture permeability is a key factor affecting its use in packaging, as it naturally allows vapor transmission that can compromise product freshness. Enhancing cellophane's moisture resistance involves coating or laminating with materials such as nitrocellulose or PVDC to create an effective moisture barrier. These treatments significantly reduce water vapor transmission rate (WVTR), extending shelf life and maintaining product quality in food and pharmaceutical packaging applications.

Comparing Cellophane to Other Packaging Materials

Cellophane exhibits moderate moisture permeability compared to plastic films like polyethylene, which offer superior moisture barrier properties critical for preserving product freshness. Unlike cellophane, which allows controlled moisture vapor transmission beneficial for certain food packaging applications, materials such as polypropylene provide a nearly impermeable barrier that extends shelf life by preventing moisture ingress. This balance makes cellophane preferable for packaging items requiring breathability, whereas plastics suit products needing stringent moisture protection.

Impact of Moisture Properties on Cellophane Shelf Life

Cellophane's moisture permeability plays a crucial role in determining its effectiveness as a moisture barrier, directly impacting shelf life by controlling the rate of moisture transfer between the environment and packaged goods. High moisture permeability can lead to faster spoilage of products sensitive to humidity, such as food and pharmaceuticals, while low permeability enhances protection by reducing moisture ingress. Optimizing the moisture barrier properties of cellophane extends shelf life by maintaining product quality and preventing microbial growth associated with excess moisture.

Moisture permeability vs Moisture barrier Infographic

materialdif.com

materialdif.com