Biodegradable cellophane is derived from cellulose and breaks down naturally in the environment without leaving harmful residues, making it an eco-friendly alternative to traditional plastics. Compostable PLA film, made from polylactic acid sourced from renewable resources like corn starch, decomposes under industrial composting conditions within a specific timeframe. While both options reduce plastic pollution, biodegradable cellophane offers a broader range of disposal options and environmental benefits compared to the more specialized composting requirements of PLA film.

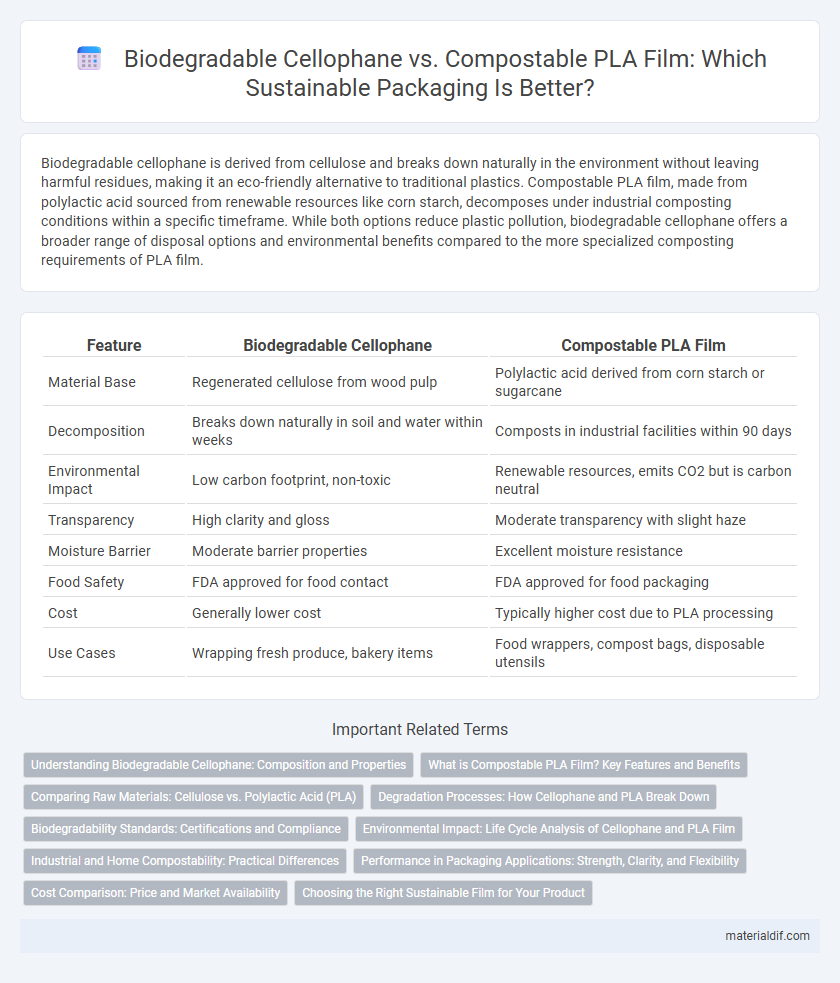

Table of Comparison

| Feature | Biodegradable Cellophane | Compostable PLA Film |

|---|---|---|

| Material Base | Regenerated cellulose from wood pulp | Polylactic acid derived from corn starch or sugarcane |

| Decomposition | Breaks down naturally in soil and water within weeks | Composts in industrial facilities within 90 days |

| Environmental Impact | Low carbon footprint, non-toxic | Renewable resources, emits CO2 but is carbon neutral |

| Transparency | High clarity and gloss | Moderate transparency with slight haze |

| Moisture Barrier | Moderate barrier properties | Excellent moisture resistance |

| Food Safety | FDA approved for food contact | FDA approved for food packaging |

| Cost | Generally lower cost | Typically higher cost due to PLA processing |

| Use Cases | Wrapping fresh produce, bakery items | Food wrappers, compost bags, disposable utensils |

Understanding Biodegradable Cellophane: Composition and Properties

Biodegradable cellophane, derived from cellulose obtained from wood pulp or cotton fibers, decomposes naturally through microbial activity, offering an eco-friendly alternative to petrochemical-based plastics. Its transparent, flexible properties make it ideal for packaging applications while allowing oxygen permeability, which supports freshness in food products. Unlike compostable PLA film, which is based on polylactic acid from fermented plant starch, biodegradable cellophane breaks down more readily in natural environments without specialized composting conditions.

What is Compostable PLA Film? Key Features and Benefits

Compostable PLA film is a bioplastic derived from renewable resources like corn starch or sugarcane, designed to break down in industrial composting environments within 90 to 180 days. Key features include excellent transparency, moisture resistance, and biodegradability, making it ideal for sustainable packaging applications. Benefits of compostable PLA film encompass reduced carbon footprint, compatibility with existing composting systems, and elimination of persistent plastic waste in landfills and oceans.

Comparing Raw Materials: Cellulose vs. Polylactic Acid (PLA)

Biodegradable cellophane is derived from cellulose, a natural polymer extracted from wood pulp or cotton fibers, which breaks down through microbial activity without leaving harmful residues. Compostable PLA film is made from polylactic acid, a bioplastic synthesized from fermented plant sugars such as corn starch or sugarcane, and decomposes into water and carbon dioxide under industrial composting conditions. The cellulose in cellophane offers renewable, sustainable origins with inherent biodegradability, whereas PLA relies on agricultural feedstocks and requires specific composting environments for effective degradation.

Degradation Processes: How Cellophane and PLA Break Down

Cellophane, made from cellulose, breaks down through microbial activity that decomposes the natural fibers into water, carbon dioxide, and biomass, typically requiring industrial composting conditions or natural soil environments. PLA film, derived from polylactic acid, undergoes hydrolytic degradation followed by microbial assimilation, but its breakdown is significantly slower in natural environments and usually requires industrial composting facilities with high temperature and humidity. The difference in degradation rates highlights that cellophane is more readily biodegradable, while PLA film is compostable under specialized conditions, impacting their environmental disposal pathways.

Biodegradability Standards: Certifications and Compliance

Biodegradable cellophane typically meets international standards such as ASTM D6400 and EN 13432, certifying its ability to break down naturally within a specified timeframe without leaving harmful residues. Compostable PLA film also adheres to these certifications but is specifically designed to decompose in industrial composting conditions, highlighting differences in end-of-life scenarios. Understanding these standards is essential for manufacturers and consumers aiming for sustainable packaging solutions compliant with environmental regulations.

Environmental Impact: Life Cycle Analysis of Cellophane and PLA Film

Biodegradable cellophane, derived from cellulose, breaks down naturally without releasing harmful microplastics, offering a lower environmental footprint compared to compostable PLA film, which requires industrial composting conditions to degrade effectively. Life cycle analysis reveals that cellophane production consumes fewer fossil fuels and generates less greenhouse gas emissions than PLA, whose manufacturing relies on energy-intensive fermentation of corn starch. The environmental impact of cellophane is further mitigated by its renewable raw materials and biodegradability in various ecosystems, contrasting with PLA's limited compostability outside controlled facilities.

Industrial and Home Compostability: Practical Differences

Biodegradable cellophane, made from cellulose, decomposes efficiently in industrial composting facilities but may not break down effectively in home composting environments due to temperature and microbial activity requirements. Compostable PLA film, derived from polylactic acid, also requires industrial composting conditions to fully degrade, often taking longer to decompose than cellophane. The practical difference lies in degradation speed and environmental conditions: cellophane is more adaptable to various composting setups, while PLA demands controlled industrial settings for complete compostability.

Performance in Packaging Applications: Strength, Clarity, and Flexibility

Biodegradable cellophane offers superior clarity and high tensile strength, making it an excellent choice for visually appealing and durable packaging applications. Compostable PLA film provides good flexibility and moisture resistance but often lacks the same strength and clarity levels as cellophane, which can impact product visibility and protection. In terms of performance, biodegradable cellophane is preferred for packaging requiring clear presentation and robust protection, while PLA film suits applications where compostability and flexibility are the primary concerns.

Cost Comparison: Price and Market Availability

Biodegradable cellophane typically costs more than compostable PLA film due to its natural cellulose base and limited production scale, impacting market availability. PLA film benefits from larger industrial production, driving lower prices and wider availability in packaging applications. Cost efficiency of PLA film positions it as a favorable option for businesses seeking sustainable yet affordable packaging solutions.

Choosing the Right Sustainable Film for Your Product

Biodegradable cellophane, derived from cellulose, offers excellent clarity and moisture resistance while breaking down naturally without leaving harmful residues, making it ideal for eco-conscious packaging. Compostable PLA film, made from renewable resources like corn starch, provides strength and heat resistance but requires industrial composting facilities for complete decomposition. Selecting the right sustainable film depends on your product's shelf life, disposal infrastructure, and environmental impact priorities to ensure optimal performance and eco-friendliness.

Biodegradable Cellophane vs Compostable PLA Film Infographic

materialdif.com

materialdif.com