Cellophane lamination offers a glossy, biodegradable finish that enhances print clarity and provides moderate water resistance, making it ideal for eco-friendly packaging solutions. Polyethylene lamination delivers superior durability and moisture protection, extending the shelf life of products but is less environmentally sustainable due to its plastic composition. Choosing between cellophane and polyethylene lamination depends on the balance between environmental impact and the level of protection required for the packaged goods.

Table of Comparison

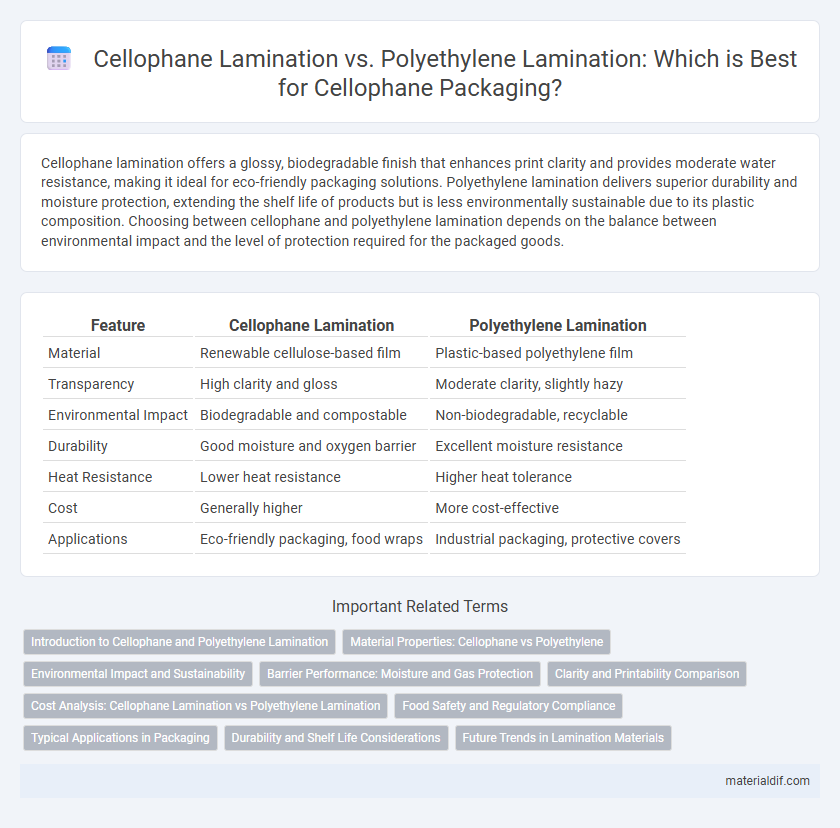

| Feature | Cellophane Lamination | Polyethylene Lamination |

|---|---|---|

| Material | Renewable cellulose-based film | Plastic-based polyethylene film |

| Transparency | High clarity and gloss | Moderate clarity, slightly hazy |

| Environmental Impact | Biodegradable and compostable | Non-biodegradable, recyclable |

| Durability | Good moisture and oxygen barrier | Excellent moisture resistance |

| Heat Resistance | Lower heat resistance | Higher heat tolerance |

| Cost | Generally higher | More cost-effective |

| Applications | Eco-friendly packaging, food wraps | Industrial packaging, protective covers |

Introduction to Cellophane and Polyethylene Lamination

Cellophane lamination involves a thin, transparent cellulose film that offers excellent breathability and natural biodegradability, making it ideal for eco-friendly packaging solutions. Polyethylene lamination uses a plastic film that provides superior moisture resistance, durability, and flexibility, enhancing product protection against external elements. Both lamination methods improve packaging strength and appearance but differ significantly in environmental impact and barrier properties.

Material Properties: Cellophane vs Polyethylene

Cellophane lamination offers superior breathability and biodegradability compared to polyethylene lamination, making it ideal for eco-friendly packaging solutions. Polyethylene lamination provides enhanced moisture resistance and durability, which is essential for protecting products from water and physical damage. While cellophane is transparent and enhances print clarity, polyethylene typically exhibits greater flexibility and tear resistance, influencing the choice based on specific material property requirements.

Environmental Impact and Sustainability

Cellophane lamination offers superior environmental benefits due to its biodegradable and compostable nature, derived from renewable cellulose sources, reducing long-term landfill waste. Polyethylene lamination, while effective as a moisture barrier, is petroleum-based and non-biodegradable, contributing significantly to plastic pollution and carbon emissions. Choosing cellophane over polyethylene supports sustainability goals by minimizing environmental footprint and enhancing recyclability in packaging applications.

Barrier Performance: Moisture and Gas Protection

Cellophane lamination offers superior moisture barrier properties due to its natural cellulose fibers, making it highly effective in preventing water vapor transmission. In contrast, polyethylene lamination excels in gas barrier protection, particularly against oxygen and carbon dioxide, enhancing the shelf life of perishable goods. Combining cellophane with polyethylene layers often results in optimized barrier performance, balancing moisture resistance and gas protection for diverse packaging applications.

Clarity and Printability Comparison

Cellophane lamination offers superior clarity with a natural gloss finish, making it ideal for high-visibility packaging where product appearance is crucial. Polyethylene lamination provides a less transparent, often matte surface that may obscure fine print details, affecting overall print quality. When printability is the priority, cellophane supports sharper, more vibrant images and text due to its smooth, receptive surface compared to the more porous texture of polyethylene.

Cost Analysis: Cellophane Lamination vs Polyethylene Lamination

Cellophane lamination typically incurs higher material costs compared to polyethylene lamination due to its biodegradable cellulose base and production process. Polyethylene lamination offers a more cost-effective solution with lower raw material expenses and simpler manufacturing, making it ideal for budget-sensitive packaging. Evaluating long-term environmental impact costs and market preference for sustainable packaging can influence the overall cost-benefit analysis between these two lamination options.

Food Safety and Regulatory Compliance

Cellophane lamination offers superior breathability and biodegradability, making it ideal for food packaging with strict food safety standards and compliance with FDA and EU regulations. Polyethylene lamination, while providing excellent moisture barrier properties, may pose challenges for sustainability and requires careful consideration of regulatory limits on plastic usage. Choosing cellophane lamination ensures enhanced freshness retention and meets stringent environmental and safety requirements critical for food-grade packaging.

Typical Applications in Packaging

Cellophane lamination offers excellent breathability and biodegradability, making it ideal for food packaging such as bakery items, fresh produce, and confectionery where moisture control and eco-friendliness are critical. Polyethylene lamination provides superior moisture resistance and durability, commonly used in packaging for snacks, frozen foods, and pharmaceutical products requiring airtight seals and extended shelf life. Both materials cater to different packaging needs, balancing protection, appearance, and environmental considerations based on the product's storage and display requirements.

Durability and Shelf Life Considerations

Cellophane lamination offers superior breathability and biodegradability, making it ideal for products requiring moisture control and extended freshness. Polyethylene lamination provides enhanced durability and moisture resistance, extending shelf life by protecting against water and contaminants. Choosing between cellophane and polyethylene lamination depends on the specific packaging needs for preserving product integrity and sustainability goals.

Future Trends in Lamination Materials

Cellophane lamination offers superior biodegradability compared to polyethylene lamination, aligning with the growing demand for sustainable packaging solutions in the future. Emerging trends emphasize the development of bio-based polyethylene alternatives and enhanced barrier properties in cellophane to improve shelf life without compromising environmental benefits. Innovations in nanocomposite coatings and recyclable lamination layers are expected to drive significant advancements in eco-friendly lamination materials.

Cellophane Lamination vs Polyethylene Lamination Infographic

materialdif.com

materialdif.com