Cellophane tape is a transparent, thin, and flexible adhesive tape primarily used for light-duty tasks such as sealing envelopes or wrapping gifts. Adhesive tape encompasses a broader category, including various types like duct tape, masking tape, and double-sided tape, each designed for specific heavy-duty or specialized applications. While cellophane tape offers clear visibility and ease of use, adhesive tape provides stronger bonding durability and versatility across different surfaces.

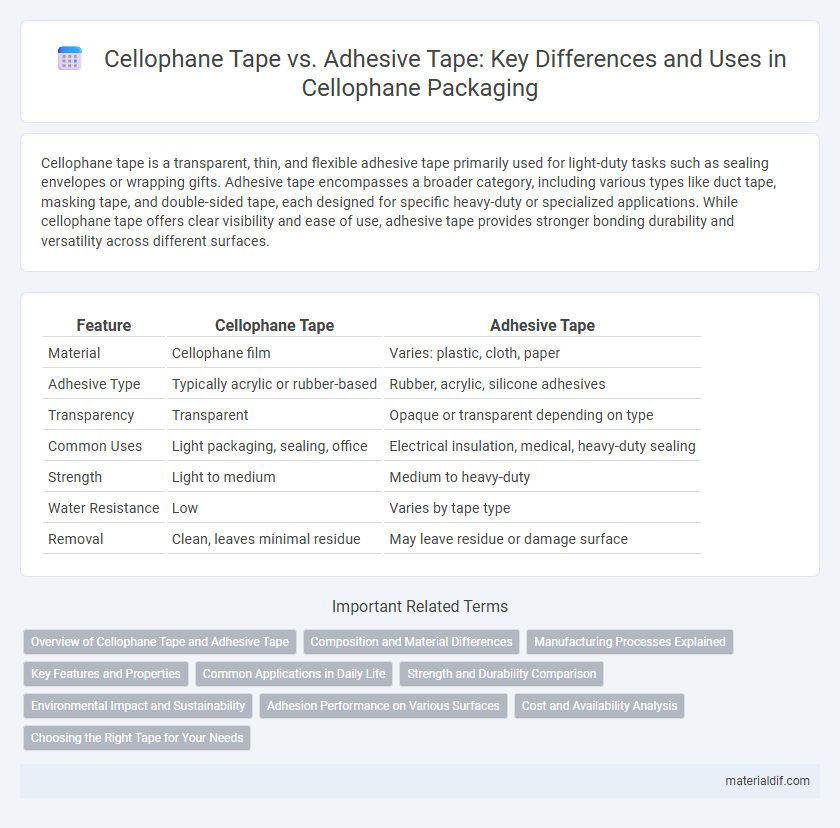

Table of Comparison

| Feature | Cellophane Tape | Adhesive Tape |

|---|---|---|

| Material | Cellophane film | Varies: plastic, cloth, paper |

| Adhesive Type | Typically acrylic or rubber-based | Rubber, acrylic, silicone adhesives |

| Transparency | Transparent | Opaque or transparent depending on type |

| Common Uses | Light packaging, sealing, office | Electrical insulation, medical, heavy-duty sealing |

| Strength | Light to medium | Medium to heavy-duty |

| Water Resistance | Low | Varies by tape type |

| Removal | Clean, leaves minimal residue | May leave residue or damage surface |

Overview of Cellophane Tape and Adhesive Tape

Cellophane tape, a transparent adhesive tape made from cellulose film, offers excellent clarity and is commonly used for sealing and wrapping purposes in packaging and office settings. Adhesive tape, a broader category, includes various types like masking, duct, and electrical tapes, each designed with different backing materials and adhesive properties tailored for specific applications. Choosing between cellophane tape and adhesive tape depends on the required strength, transparency, and surface compatibility for the task.

Composition and Material Differences

Cellophane tape is made primarily from cellulose film with a pressure-sensitive adhesive, offering transparency and biodegradability, whereas adhesive tape typically uses plastic films like polypropylene or PVC combined with synthetic adhesives for durability and stronger bonding. The natural cellulose base in cellophane tape results in a more eco-friendly alternative compared to the petrochemical-derived materials in most adhesive tapes. These composition differences influence the tapes' flexibility, transparency, and environmental impact, making cellophane tape preferred for light-duty, recyclable applications.

Manufacturing Processes Explained

Cellophane tape is produced by coating regenerated cellulose film with a natural rubber or synthetic adhesive, resulting in a transparent, flexible backing that adheres smoothly to surfaces. In contrast, adhesive tape manufacturing often involves a plastic film base such as polypropylene or PVC, which is coated with varied adhesive types including acrylic, rubber, or silicone. The manufacturing process for cellophane tape emphasizes biodegradability and natural raw materials, while adhesive tape production prioritizes durability and specialized adhesive formulations for different industrial applications.

Key Features and Properties

Cellophane tape is a transparent, thin adhesive tape primarily made from cellulose and offers excellent clarity and flexibility, making it ideal for light packaging and everyday household use. Adhesive tape, a broader category, includes various materials like plastic, cloth, and rubber-based tapes with different adhesive strengths designed for specialized applications such as heavy-duty sealing, electrical insulation, or mounting. Key features of cellophane tape include biodegradability and ease of tearing, whereas adhesive tapes emphasize durability, resistance to moisture, and stronger adhesion depending on their composition.

Common Applications in Daily Life

Cellophane tape is widely used for lightweight packaging, gift wrapping, and simple paper repairs due to its transparent and low-tack adhesive properties. Adhesive tape, such as duct tape or masking tape, offers stronger bonding and durability, making it ideal for sealing boxes, repairing household items, and general construction tasks. Both tapes serve essential functions in daily life, with cellophane tape favored for delicate tasks and adhesive tape preferred for heavier-duty applications.

Strength and Durability Comparison

Cellophane tape typically has lower tensile strength and diminished durability compared to adhesive tape, which often utilizes stronger synthetic materials like polypropylene or PVC. Adhesive tape variants generally exhibit superior resistance to tearing, temperature fluctuations, and long-term wear, making them ideal for industrial and heavy-duty applications. The inherent fragility of cellophane tape limits its effectiveness for tasks requiring sustained adhesion and mechanical strength.

Environmental Impact and Sustainability

Cellophane tape, made from biodegradable cellulose, offers a more environmentally sustainable alternative to conventional adhesive tape, which often contains non-biodegradable plastics like polypropylene. The cellulose composition of cellophane tape allows it to decompose naturally, reducing landfill waste and microplastic pollution compared to synthetic adhesive tapes. Choosing cellophane tape supports eco-friendly packaging and waste management practices by minimizing long-term environmental impact.

Adhesion Performance on Various Surfaces

Cellophane tape typically features lower adhesion performance on rough or oily surfaces compared to adhesive tape, which contains stronger synthetic adhesives formulated for diverse material bonding. Adhesive tapes often incorporate acrylic or rubber-based adhesives, enabling superior grip on porous, metal, plastic, and painted surfaces. The enhanced adhesion properties of adhesive tapes make them ideal for industrial, packaging, and household applications requiring reliable surface contact and durability.

Cost and Availability Analysis

Cellophane tape generally costs less than many types of adhesive tape due to its simpler production process and widespread manufacturing. It is widely available in most retail stores and online, making it a convenient choice for everyday use. In contrast, adhesive tapes, which include variants like duct tape or double-sided tape, often carry higher prices and may be less commonly stocked depending on their specific applications or specialty materials.

Choosing the Right Tape for Your Needs

Cellophane tape, made from cellulose, offers transparency and a smooth finish ideal for paper-based projects and light-duty applications. Adhesive tape, often composed of plastic or vinyl, provides stronger bonding and greater durability, making it suitable for heavy-duty repairs and packaging. Selecting the right tape depends on the task requirements, with cellophane tape favored for crafting and office use, while adhesive tape excels in industrial and outdoor settings.

Cellophane Tape vs Adhesive Tape Infographic

materialdif.com

materialdif.com