Cellophane packaging, made from cellulose derived from wood pulp, offers excellent breathability and compostability, making it an eco-friendly alternative to traditional plastics. Biodegradable plastic packaging, often manufactured from plant-based polymers, breaks down more quickly than conventional plastics but may require specific conditions to fully degrade. Choosing cellophane ensures a natural, non-toxic option that reduces environmental impact while maintaining product freshness.

Table of Comparison

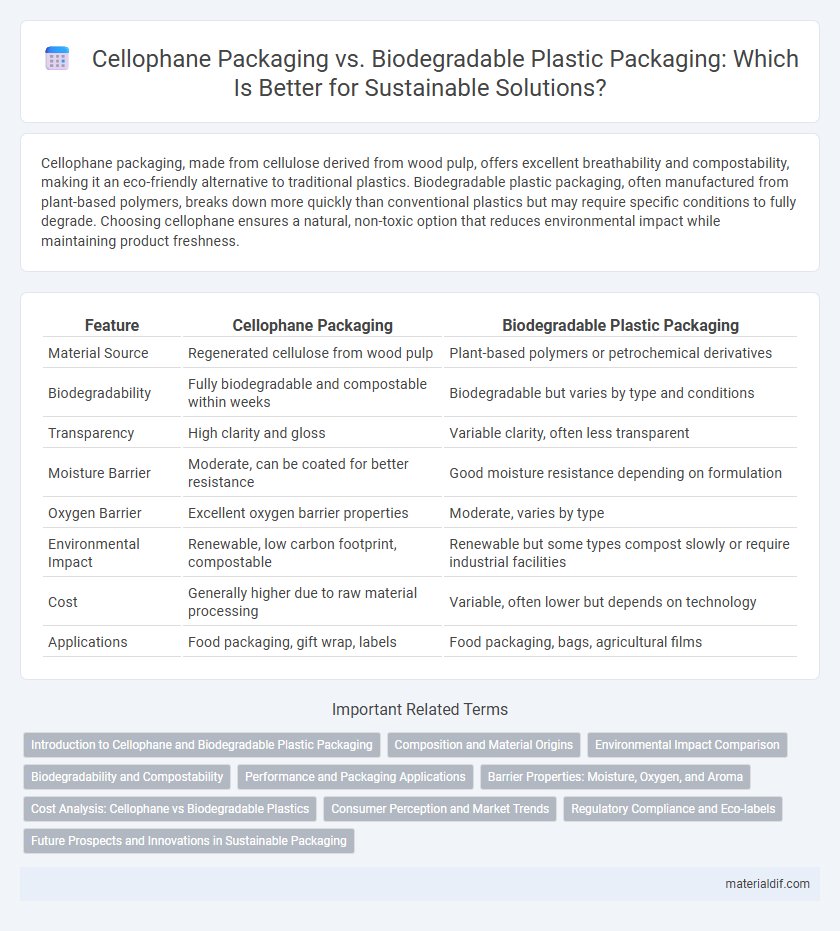

| Feature | Cellophane Packaging | Biodegradable Plastic Packaging |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Plant-based polymers or petrochemical derivatives |

| Biodegradability | Fully biodegradable and compostable within weeks | Biodegradable but varies by type and conditions |

| Transparency | High clarity and gloss | Variable clarity, often less transparent |

| Moisture Barrier | Moderate, can be coated for better resistance | Good moisture resistance depending on formulation |

| Oxygen Barrier | Excellent oxygen barrier properties | Moderate, varies by type |

| Environmental Impact | Renewable, low carbon footprint, compostable | Renewable but some types compost slowly or require industrial facilities |

| Cost | Generally higher due to raw material processing | Variable, often lower but depends on technology |

| Applications | Food packaging, gift wrap, labels | Food packaging, bags, agricultural films |

Introduction to Cellophane and Biodegradable Plastic Packaging

Cellophane, a transparent film made from cellulose, offers excellent oxygen and moisture barrier properties ideal for food packaging. Biodegradable plastic packaging, derived from plant-based polymers such as polylactic acid (PLA), decomposes naturally under industrial composting conditions, reducing environmental impact. Both materials serve as sustainable alternatives to conventional plastics, with cellophane providing superior clarity and biodegradability, while biodegradable plastics offer versatility in shape and strength.

Composition and Material Origins

Cellophane packaging is derived from regenerated cellulose, sourced primarily from wood pulp, making it a natural and renewable material with excellent biodegradability. In contrast, biodegradable plastic packaging typically consists of synthetic polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), produced through microbial fermentation of plant-based sugars or petrochemical derivatives. These differences in composition and material origins affect their environmental impact, with cellophane offering compostability without relying on industrial biodegradation conditions.

Environmental Impact Comparison

Cellophane packaging, derived from cellulose, offers superior biodegradability compared to most biodegradable plastics, which often contain synthetic additives slowing decomposition. Its natural composition allows cellophane to break down in weeks under composting conditions, reducing landfill accumulation and microplastic pollution. In contrast, some biodegradable plastics require industrial composting facilities to degrade effectively, potentially limiting their environmental benefits in typical waste systems.

Biodegradability and Compostability

Cellophane packaging is derived from regenerated cellulose and offers excellent biodegradability, breaking down naturally in weeks under composting conditions without releasing harmful microplastics. Biodegradable plastic packaging, often made from polylactic acid (PLA) or other biopolymers, requires specific industrial composting environments to decompose efficiently, which may limit its compostability in home settings. While both materials support sustainable disposal, cellophane's natural compostability and ability to degrade in diverse conditions provide a distinct advantage over many biodegradable plastics.

Performance and Packaging Applications

Cellophane packaging offers superior breathability and clarity compared to biodegradable plastic packaging, making it ideal for fresh produce and confectionery that require moisture control and visual appeal. Biodegradable plastics often provide greater flexibility and resistance to grease and oils, suitable for packaging baked goods and ready-to-eat meals where barrier properties are crucial. Performance choice depends on application needs: cellophane excels in freshness preservation and sustainability, while biodegradable plastics deliver enhanced durability and broader compatibility with diverse food products.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane packaging offers superior moisture and oxygen barrier properties compared to many biodegradable plastics, making it ideal for preserving food freshness and aroma. Its natural cellulose structure effectively limits gas permeability, reducing oxidation and spoilage risks. However, certain advanced biodegradable plastics now incorporate enhanced barrier layers to compete with cellophane's performance in moisture and aroma retention.

Cost Analysis: Cellophane vs Biodegradable Plastics

Cellophane packaging generally offers a lower production cost compared to biodegradable plastics due to its simpler manufacturing process derived from cellulose. Biodegradable plastics often require more expensive raw materials and specialized processing, resulting in higher overall costs. While cellophane provides cost efficiency, biodegradable plastics may incur additional expenses for environmental compliance and waste management.

Consumer Perception and Market Trends

Cellophane packaging is often perceived by consumers as a more natural and eco-friendly option compared to biodegradable plastic packaging, which can be associated with synthetic materials despite its compostability. Market trends indicate a growing demand for cellophane due to its renewable cellulose base and transparent appearance that enhances product visibility. Consumer preference is increasingly shifting toward sustainable packaging solutions, with cellophane gaining traction in organic and premium product segments owing to its biodegradability and lower environmental impact.

Regulatory Compliance and Eco-labels

Cellophane packaging, derived from cellulose, complies with stringent regulatory standards such as FDA and EU food contact approvals, while many biodegradable plastics face ongoing evaluation for similar certifications. Eco-labels like FSC certification commonly apply to cellophane owing to its renewable material origin, whereas biodegradable plastics often seek certification from organizations like TUV Austria's OK compost or the Biodegradable Products Institute (BPI). Regulatory compliance ensures product safety and market access, making eco-labels crucial for consumer transparency and environmental responsibility in packaging choices.

Future Prospects and Innovations in Sustainable Packaging

Cellophane packaging exhibits a significant advantage in biodegradability, breaking down naturally within weeks, whereas many biodegradable plastics require industrial composting facilities for full degradation. Innovations in sustainable packaging are increasingly focused on enhancing the moisture barrier properties and durability of cellophane through bio-based coatings and nanotechnology, aiming to expand its applicability across diverse industries. Future prospects highlight the integration of cellophane with smart packaging technologies and improved recyclability, positioning it as a leading sustainable alternative to conventional biodegradable plastics.

Cellophane Packaging vs Biodegradable Plastic Packaging Infographic

materialdif.com

materialdif.com