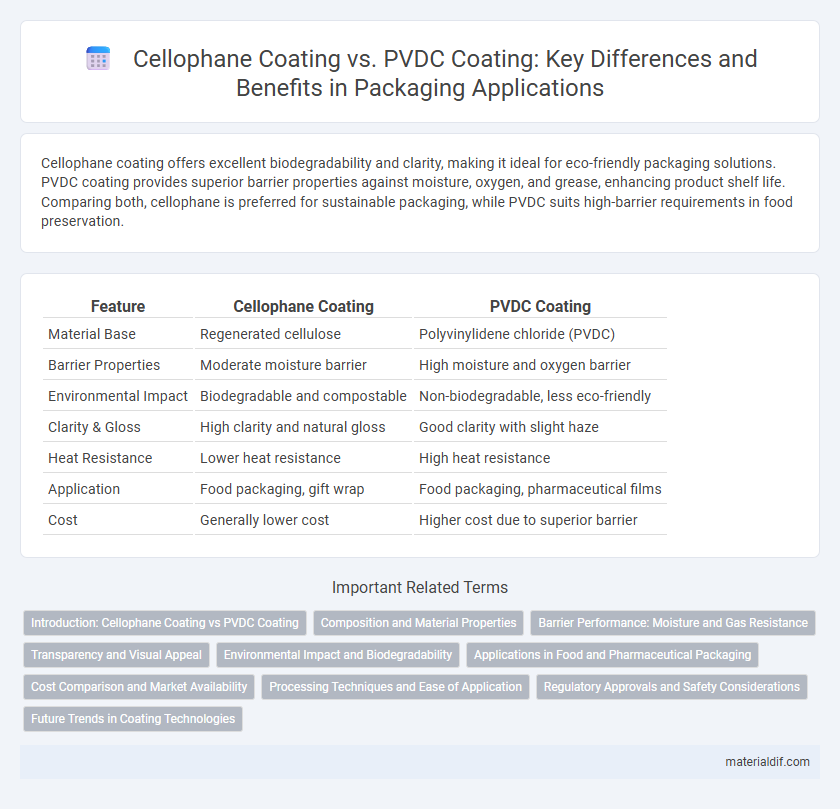

Cellophane coating offers excellent biodegradability and clarity, making it ideal for eco-friendly packaging solutions. PVDC coating provides superior barrier properties against moisture, oxygen, and grease, enhancing product shelf life. Comparing both, cellophane is preferred for sustainable packaging, while PVDC suits high-barrier requirements in food preservation.

Table of Comparison

| Feature | Cellophane Coating | PVDC Coating |

|---|---|---|

| Material Base | Regenerated cellulose | Polyvinylidene chloride (PVDC) |

| Barrier Properties | Moderate moisture barrier | High moisture and oxygen barrier |

| Environmental Impact | Biodegradable and compostable | Non-biodegradable, less eco-friendly |

| Clarity & Gloss | High clarity and natural gloss | Good clarity with slight haze |

| Heat Resistance | Lower heat resistance | High heat resistance |

| Application | Food packaging, gift wrap | Food packaging, pharmaceutical films |

| Cost | Generally lower cost | Higher cost due to superior barrier |

Introduction: Cellophane Coating vs PVDC Coating

Cellophane coating offers a biodegradable and moisture-resistant barrier primarily composed of regenerated cellulose, making it ideal for eco-friendly packaging solutions. PVDC coating, derived from polyvinylidene chloride, provides superior oxygen and moisture barrier properties, extending shelf life for perishable goods. Both coatings serve distinct purposes in packaging, with cellophane focusing on sustainability and PVDC emphasizing enhanced preservation performance.

Composition and Material Properties

Cellophane coating is derived from regenerated cellulose, offering high transparency, biodegradability, and excellent oxygen permeability, making it ideal for food packaging requiring breathability. PVDC coating consists of polyvinylidene chloride, known for superior barrier properties against moisture, oxygen, and aromas, enhancing product shelf life but with limited biodegradability. The cellulose base of cellophane provides flexibility and environmental benefits, while PVDC coatings prioritize barrier performance through synthetic polymer composition.

Barrier Performance: Moisture and Gas Resistance

Cellophane coating provides moderate moisture resistance but has limited gas barrier properties, making it suitable for packaging applications where light protection and breathability are prioritized. PVDC coating enhances cellophane by offering superior moisture and gas barrier performance, significantly reducing oxygen and water vapor transmission rates. This makes PVDC-coated cellophane ideal for preserving freshness and extending shelf life in food packaging.

Transparency and Visual Appeal

Cellophane coating offers superior transparency and a natural gloss that enhances the visual appeal of packaging by providing a clear, vibrant view of the product inside. PVDC coating, while effective for moisture and gas barrier properties, often imparts a slightly cloudy or hazy finish that can reduce overall clarity and brightness. For applications prioritizing visual impact and product visibility, cellophane coating remains the preferred choice due to its unmatched clarity and aesthetic quality.

Environmental Impact and Biodegradability

Cellophane coating, derived from cellulose, exhibits superior biodegradability and minimal environmental impact compared to PVDC coating, which is a chlorinated polymer known for its persistence and difficulty in recycling. PVDC coatings release harmful dioxins during incineration and degrade slowly, contributing to long-term ecological damage. Cellophane's renewable origin and compatibility with composting processes make it a more sustainable choice for packaging applications seeking eco-friendly alternatives.

Applications in Food and Pharmaceutical Packaging

Cellophane coating offers superior breathability and biodegradability, making it ideal for packaging fresh produce and bakery items that require moisture control and environmental sustainability. PVDC coating provides excellent barrier properties against oxygen, moisture, and aromas, enhancing shelf life for pharmaceutical blister packs and oxygen-sensitive food products like meats and cheeses. Both coatings are used to optimize product protection and extend freshness, with cellophane favored for eco-friendly packaging and PVDC preferred for high-barrier requirements.

Cost Comparison and Market Availability

Cellophane coating generally costs less than PVDC coating due to its simpler manufacturing process and lower raw material expenses, making it a budget-friendly option for packaging applications. PVDC coating, while more expensive, offers superior barrier properties against moisture and gases but has limited market availability caused by environmental regulations restricting its use. The broader accessibility and cost-effectiveness of cellophane coatings make them a preferred choice for many industries prioritizing affordability and biodegradability.

Processing Techniques and Ease of Application

Cellophane coating offers a straightforward application process due to its natural cellulose base, which allows for easier adhesion and compatibility with biodegradable inks and adhesives during processing. PVDC coating involves more complex, solvent-based techniques requiring precise temperature control for optimal barrier properties, making application more intricate and energy-intensive. The simpler processing and eco-friendly nature of cellophane coatings contribute to faster production cycles and reduced environmental impact compared to the specialized handling needed for PVDC coatings.

Regulatory Approvals and Safety Considerations

Cellophane coating is recognized for its biodegradability and is often approved by food safety authorities worldwide due to its non-toxic and environmentally friendly properties. PVDC coating, while offering superior moisture and oxygen barrier properties, faces regulatory scrutiny because it contains chlorine, raising concerns about potential release of harmful substances during disposal or incineration. Safety considerations favor cellophane in applications requiring sustainable packaging, whereas PVDC is restricted or regulated in regions with strict environmental laws.

Future Trends in Coating Technologies

Future trends in coating technologies emphasize sustainable, biodegradable materials like Cellophane coatings due to increasing environmental regulations and consumer demand for eco-friendly packaging. PVDC coatings, traditionally valued for their superior barrier properties, face challenges related to recyclability and chemical usage, prompting research into alternative coatings with comparable performance. Innovations in nanocoatings and bio-based polymers aim to enhance the durability and moisture resistance of Cellophane, positioning it as a viable replacement for PVDC in next-generation packaging solutions.

Cellophane Coating vs PVDC Coating Infographic

materialdif.com

materialdif.com