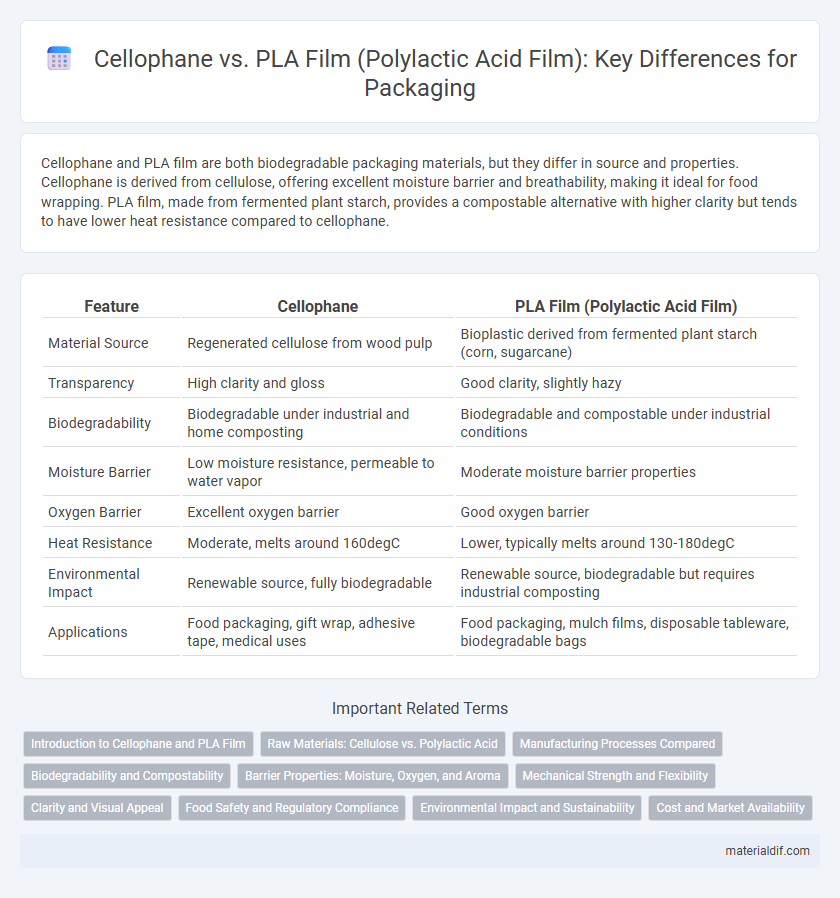

Cellophane and PLA film are both biodegradable packaging materials, but they differ in source and properties. Cellophane is derived from cellulose, offering excellent moisture barrier and breathability, making it ideal for food wrapping. PLA film, made from fermented plant starch, provides a compostable alternative with higher clarity but tends to have lower heat resistance compared to cellophane.

Table of Comparison

| Feature | Cellophane | PLA Film (Polylactic Acid Film) |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Bioplastic derived from fermented plant starch (corn, sugarcane) |

| Transparency | High clarity and gloss | Good clarity, slightly hazy |

| Biodegradability | Biodegradable under industrial and home composting | Biodegradable and compostable under industrial conditions |

| Moisture Barrier | Low moisture resistance, permeable to water vapor | Moderate moisture barrier properties |

| Oxygen Barrier | Excellent oxygen barrier | Good oxygen barrier |

| Heat Resistance | Moderate, melts around 160degC | Lower, typically melts around 130-180degC |

| Environmental Impact | Renewable source, fully biodegradable | Renewable source, biodegradable but requires industrial composting |

| Applications | Food packaging, gift wrap, adhesive tape, medical uses | Food packaging, mulch films, disposable tableware, biodegradable bags |

Introduction to Cellophane and PLA Film

Cellophane is a transparent film made from regenerated cellulose derived from wood pulp or cotton, renowned for its biodegradability and excellent moisture barrier properties. PLA film, or Polylactic Acid film, is a compostable bioplastic produced from fermented plant starch such as corn, offering strong clarity and a lower environmental impact compared to conventional plastics. Both materials serve as sustainable packaging solutions, with cellophane excelling in breathability and PLA film favored for its compostability and eco-friendly production process.

Raw Materials: Cellulose vs. Polylactic Acid

Cellophane is derived from cellulose, a natural polymer extracted from wood pulp or cotton fibers, offering biodegradability and breathability due to its plant-based origin. PLA film is made from polylactic acid, a biodegradable thermoplastic produced by fermenting renewable resources like corn starch or sugarcane, providing compostability under industrial conditions. The choice between cellulose and PLA as raw materials impacts environmental footprint, with cellulose relying on lignocellulosic biomass and PLA depending on agricultural feedstocks and fermentation processes.

Manufacturing Processes Compared

Cellophane is produced by regenerating cellulose from wood pulp, cotton, or other plant fibers through a viscose process involving chemical treatment and stretching to form a transparent film. PLA film, derived from renewable corn starch or sugarcane, undergoes polymerization of lactic acid followed by extrusion and biaxial orientation to create a biodegradable thermoplastic film. While cellophane manufacturing relies on viscose chemistry and aqueous processing, PLA film production emphasizes fermentation-based monomer synthesis and melt processing, reflecting fundamental differences in raw materials and industrial techniques.

Biodegradability and Compostability

Cellophane is a biodegradable film made from cellulose, breaking down naturally in soil and water environments without leaving harmful residues. PLA film, derived from renewable resources like corn starch, offers industrial compostability but requires specific high-temperature composting conditions for complete degradation. In contrast, cellophane's biodegradability occurs more readily in natural environments, making it a preferred eco-friendly packaging option where home composting or natural decomposition is desired.

Barrier Properties: Moisture, Oxygen, and Aroma

Cellophane offers superior moisture barrier properties compared to PLA film, effectively preventing water vapor transmission. However, PLA film demonstrates better oxygen barrier performance, making it more suitable for packaging sensitive to oxidation. Both materials provide moderate aroma barrier capabilities, with cellophane slightly outperforming PLA due to its dense cellulose structure.

Mechanical Strength and Flexibility

Cellophane offers moderate mechanical strength and excellent flexibility, making it suitable for packaging applications that require durability and adaptability to shape. PLA film exhibits higher tensile strength but is generally more brittle, reducing its flexibility compared to cellophane. When balancing mechanical strength and flexibility, cellophane provides superior pliability, while PLA film delivers enhanced strength with limited elongation capacity.

Clarity and Visual Appeal

Cellophane exhibits superior clarity with its high transparency and glossy finish, enhancing visual appeal in packaging applications. PLA film, while biodegradable and eco-friendly, typically has a slightly hazier appearance that can affect product visibility. The choice between cellophane and PLA film often depends on the need for exceptional clarity versus sustainable materials.

Food Safety and Regulatory Compliance

Cellophane, derived from cellulose, offers excellent breathability and biodegradability, making it a preferred choice for food packaging with strong regulatory approval under FDA and EU guidelines for direct food contact. PLA film, a bioplastic made from renewable resources like corn starch, complies with food safety standards but may present challenges in moisture barrier properties and industrial composting requirements. Both materials meet key regulatory frameworks, but cellophane's natural origin and superior permeability often result in better performance for fresh food packaging applications.

Environmental Impact and Sustainability

Cellophane, derived from cellulose, is biodegradable and compostable, breaking down naturally without releasing harmful microplastics, unlike PLA film which requires industrial composting facilities for proper degradation. PLA film, made from renewable plant sources like corn starch, offers lower greenhouse gas emissions during production but poses challenges in recycling due to its bioplastic composition. Evaluating environmental impact, cellophane's natural origin and ease of biodegradation contribute to greater sustainability in waste management compared to the energy-intensive processing and limited disposal options of PLA film.

Cost and Market Availability

Cellophane generally costs less than PLA film, making it a more economical choice for packaging applications. PLA film, derived from renewable resources, tends to have higher production expenses, reflecting in its higher market price. While cellophane enjoys widespread global availability due to its long-established manufacturing processes, PLA film's market presence is growing but remains limited in comparison.

Cellophane vs PLA Film (Polylactic Acid Film) Infographic

materialdif.com

materialdif.com