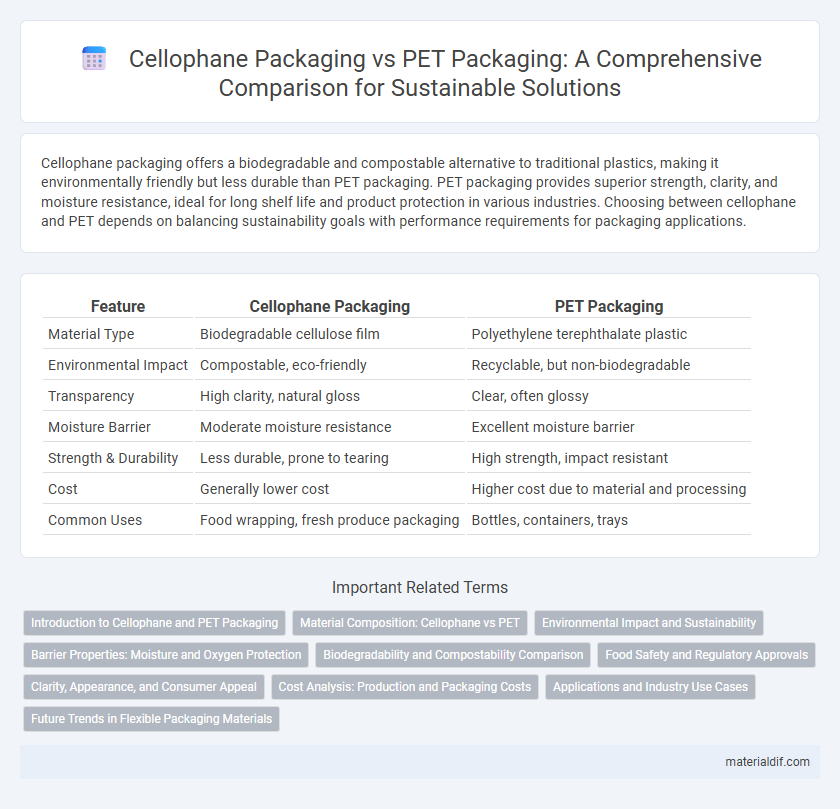

Cellophane packaging offers a biodegradable and compostable alternative to traditional plastics, making it environmentally friendly but less durable than PET packaging. PET packaging provides superior strength, clarity, and moisture resistance, ideal for long shelf life and product protection in various industries. Choosing between cellophane and PET depends on balancing sustainability goals with performance requirements for packaging applications.

Table of Comparison

| Feature | Cellophane Packaging | PET Packaging |

|---|---|---|

| Material Type | Biodegradable cellulose film | Polyethylene terephthalate plastic |

| Environmental Impact | Compostable, eco-friendly | Recyclable, but non-biodegradable |

| Transparency | High clarity, natural gloss | Clear, often glossy |

| Moisture Barrier | Moderate moisture resistance | Excellent moisture barrier |

| Strength & Durability | Less durable, prone to tearing | High strength, impact resistant |

| Cost | Generally lower cost | Higher cost due to material and processing |

| Common Uses | Food wrapping, fresh produce packaging | Bottles, containers, trays |

Introduction to Cellophane and PET Packaging

Cellophane is a biodegradable, cellulose-based film known for its excellent moisture barrier and clarity, widely used in food packaging to maintain freshness. PET (polyethylene terephthalate) packaging is a durable, recyclable plastic film favored for its strength, chemical resistance, and ability to preserve product integrity in various industries. Both materials serve distinct roles in packaging, with Cellophane offering eco-friendly advantages and PET providing superior durability and versatility.

Material Composition: Cellophane vs PET

Cellophane is derived from regenerated cellulose, a natural polymer sourced from wood pulp or cotton fibers, offering biodegradability and compostability ideal for sustainable packaging. PET (polyethylene terephthalate) is a synthetic thermoplastic polymer made from petrochemicals, prized for its durability, clarity, and recyclability but less eco-friendly due to its petroleum base. The cellulose-based composition of cellophane enables better environmental impact through biodegradability, whereas PET excels in moisture barrier properties and mechanical strength for packaging applications.

Environmental Impact and Sustainability

Cellophane packaging, made from biodegradable cellulose, offers superior environmental benefits compared to PET packaging, which relies on non-renewable petroleum-based plastics and contributes significantly to plastic pollution. Cellophane decomposes naturally within weeks, reducing landfill buildup and microplastic contamination, whereas PET can persist for centuries, posing long-term ecological threats. Sustainable sourcing of wood pulp for cellophane production further enhances its eco-friendly profile by promoting responsible forestry and reducing carbon footprints.

Barrier Properties: Moisture and Oxygen Protection

Cellophane packaging offers moderate barrier properties against moisture and oxygen, which makes it suitable for packaging fresh produce and dry goods but less effective for products requiring long shelf life. PET packaging provides superior moisture and oxygen barrier capabilities due to its dense polymer structure, enhancing protection for sensitive foods and extending product freshness. Both materials balance transparency and barrier function, but PET outperforms cellophane in preserving product integrity under high humidity and oxygen exposure conditions.

Biodegradability and Compostability Comparison

Cellophane packaging, made from cellulose derived from wood pulp, is fully biodegradable and compostable, breaking down naturally within weeks under composting conditions. PET packaging, synthesized from petroleum-based polymers, offers limited biodegradability and can persist for centuries in the environment, posing significant waste management challenges. The compostability of cellophane makes it a sustainable alternative to PET, which requires specialized recycling processes and contributes extensively to plastic pollution.

Food Safety and Regulatory Approvals

Cellophane packaging offers superior breathability and biodegradability, making it a preferred choice for organic and natural food products seeking compliance with stringent food safety standards. PET packaging, while highly durable and moisture-resistant, often requires additional chemical treatments to meet regulatory approvals for direct food contact, potentially raising concerns over migration of additives. Regulatory bodies such as the FDA and EFSA recognize both materials, but cellophane's natural origin and compostability provide a distinct advantage in meeting sustainability and food safety certifications globally.

Clarity, Appearance, and Consumer Appeal

Cellophane packaging offers superior clarity and a natural glossy appearance that enhances product visibility, making it highly appealing to consumers seeking eco-friendly options. In comparison, PET packaging provides excellent transparency and durability but often lacks the same level of natural sheen that attracts buyers. Consumer appeal leans toward cellophane for its biodegradable qualities and aesthetic advantages in showcasing freshness.

Cost Analysis: Production and Packaging Costs

Cellophane packaging generally has lower raw material costs compared to PET packaging, making it a cost-effective choice for biodegradable and eco-friendly products. Production expenses for cellophane involve lower energy consumption due to its simpler manufacturing process, while PET requires higher temperatures and more complex extrusion methods, increasing overall production costs. Packaging costs also favor cellophane in terms of recyclability and compostability, reducing waste management expenses often associated with PET packaging.

Applications and Industry Use Cases

Cellophane packaging excels in food wrapping due to its biodegradability, breathability, and moisture resistance, making it ideal for fresh produce, bakery items, and confectionery products. PET packaging offers superior durability, chemical resistance, and clarity, widely used in beverage bottles, cosmetics, and pharmaceutical containers where product safety and shelf life are critical. Industries prioritize cellophane for eco-friendly packaging solutions while selecting PET for high-strength, transparent packaging demands in mass-market and medical applications.

Future Trends in Flexible Packaging Materials

Cellophane packaging, derived from natural cellulose, offers biodegradability and superior oxygen barrier properties compared to PET packaging, which relies on petroleum-based polymers and excels in durability and moisture resistance. Emerging trends in flexible packaging emphasize sustainable materials, with innovations aimed at enhancing the recyclability of PET and improving the compostability of cellophane films. Advances in bio-based coatings and nano-enhanced barriers are expected to drive the future development of eco-friendly flexible packaging solutions.

Cellophane Packaging vs PET Packaging Infographic

materialdif.com

materialdif.com