Cellophane packaging, made from cellulose, offers excellent biodegradability and compostability compared to PLA (Polylactic Acid) packaging, which is derived from renewable plant sugars but may require industrial composting facilities to break down efficiently. Cellophane provides superior oxygen and moisture barrier properties, enhancing product freshness and shelf life, whereas PLA packaging often struggles with moisture resistance and oxygen permeability. Despite PLA's renewable source appeal, cellophane remains a more effective sustainable packaging option for applications demanding high barrier performance and environmental compatibility.

Table of Comparison

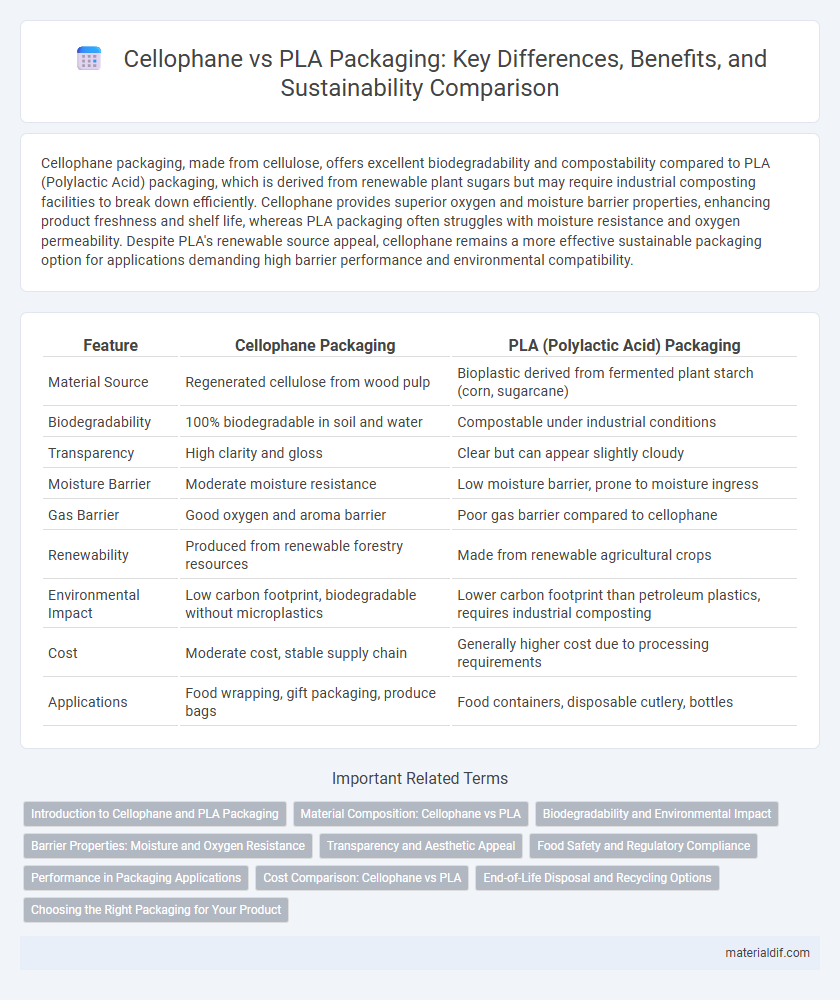

| Feature | Cellophane Packaging | PLA (Polylactic Acid) Packaging |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Bioplastic derived from fermented plant starch (corn, sugarcane) |

| Biodegradability | 100% biodegradable in soil and water | Compostable under industrial conditions |

| Transparency | High clarity and gloss | Clear but can appear slightly cloudy |

| Moisture Barrier | Moderate moisture resistance | Low moisture barrier, prone to moisture ingress |

| Gas Barrier | Good oxygen and aroma barrier | Poor gas barrier compared to cellophane |

| Renewability | Produced from renewable forestry resources | Made from renewable agricultural crops |

| Environmental Impact | Low carbon footprint, biodegradable without microplastics | Lower carbon footprint than petroleum plastics, requires industrial composting |

| Cost | Moderate cost, stable supply chain | Generally higher cost due to processing requirements |

| Applications | Food wrapping, gift packaging, produce bags | Food containers, disposable cutlery, bottles |

Introduction to Cellophane and PLA Packaging

Cellophane packaging is made from regenerated cellulose derived from wood pulp, offering a biodegradable, transparent, and moisture-resistant barrier ideal for food wrapping. PLA (Polylactic Acid) packaging is produced from renewable resources like corn starch or sugarcane, providing a compostable and environmentally friendly alternative with good clarity and stiffness. Both materials serve as sustainable packaging options, with cellophane excelling in water vapor resistance and PLA favored for its compostability and renewable origins.

Material Composition: Cellophane vs PLA

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp, making it biodegradable and compostable under industrial conditions. In contrast, PLA (Polylactic Acid) packaging is synthesized from renewable resources like corn starch or sugarcane, resulting in a bioplastic that offers similar compostability but distinct mechanical properties. Both materials provide sustainable alternatives to conventional plastics, with cellophane's natural cellulose structure differing fundamentally from PLA's polymer-based composition.

Biodegradability and Environmental Impact

Cellophane packaging, made from cellulose derived from wood pulp, is fully biodegradable and compostable, breaking down naturally in soil without releasing harmful toxins, making it an eco-friendly alternative to traditional plastics. PLA packaging, produced from renewable resources like corn starch, also offers biodegradability but typically requires industrial composting conditions to decompose effectively. Compared to PLA, cellophane has a lower environmental impact due to its ability to degrade in natural environments, reducing landfill waste and microplastic pollution.

Barrier Properties: Moisture and Oxygen Resistance

Cellophane packaging offers superior moisture resistance due to its natural cellulose structure, effectively preventing water vapor transmission compared to PLA packaging. PLA packaging, while biodegradable, exhibits higher oxygen permeability, making it less effective at preserving products sensitive to oxidation. Both materials provide eco-friendly solutions, but cellophane's enhanced barrier properties make it ideal for applications requiring extended shelf life and moisture protection.

Transparency and Aesthetic Appeal

Cellophane packaging offers superior transparency with a glossy, glass-like finish that enhances the aesthetic appeal of products by allowing clear visibility and vibrant color presentation. PLA (Polylactic Acid) packaging, while biodegradable, often has a slightly hazy or matte appearance that can obscure product details and reduce visual impact. For brands prioritizing high clarity and an attractive, polished look, cellophane remains the preferred choice over PLA packaging.

Food Safety and Regulatory Compliance

Cellophane packaging, made from regenerated cellulose, offers excellent breathability and moisture resistance, making it ideal for preserving the freshness of various food products while complying with FDA and EU food contact material regulations. PLA (Polylactic Acid) packaging, derived from renewable resources like corn starch, is biodegradable and compostable but may pose challenges in maintaining moisture barrier properties and meeting strict food safety standards for long shelf-life products. Both materials must undergo rigorous testing to ensure they meet limits for contaminants, migration levels, and microbial safety to comply with food safety regulations in different markets.

Performance in Packaging Applications

Cellophane packaging offers excellent moisture and gas barrier properties, making it ideal for preserving freshness in food products, while PLA packaging provides compostability but generally has lower barrier performance. The tensile strength of cellophane surpasses PLA, ensuring better durability and resistance to tearing during handling and transport. Despite its biodegradable nature, PLA often requires specific industrial composting conditions, whereas cellophane can be both biodegradable and compostable, depending on its source and processing.

Cost Comparison: Cellophane vs PLA

Cellophane packaging typically offers a lower production cost compared to PLA (Polylactic Acid) packaging due to its simpler manufacturing process and use of cheaper raw materials derived from cellulose. PLA packaging, produced from renewable corn starch or sugarcane, involves higher processing expenses and specialized equipment, making it more expensive on a per-unit basis. Cost efficiency of cellophane makes it a preferred option for large-scale applications where budget constraints are critical, despite PLA's environmental benefits.

End-of-Life Disposal and Recycling Options

Cellophane packaging, derived from cellulose, is biodegradable and compostable, making it suitable for industrial composting but less common in home composting environments. PLA (Polylactic Acid) packaging, a bioplastic made from renewable resources like corn starch, requires specific industrial composting facilities for effective degradation and is not widely accepted in standard recycling streams. Both materials offer eco-friendly alternatives to traditional plastics, but their end-of-life disposal depends heavily on local waste management infrastructure and industrial composting availability.

Choosing the Right Packaging for Your Product

Cellophane packaging offers superior biodegradability and moisture resistance, making it ideal for fresh food products requiring breathability and environmental sustainability. PLA packaging, derived from renewable resources like corn starch, excels in compostability and clarity but may lack the moisture barrier needed for certain items. Selecting the right packaging depends on product sensitivity to moisture, desired shelf life, and consumer preferences for eco-friendly materials.

Cellophane Packaging vs PLA (Polylactic Acid) Packaging Infographic

materialdif.com

materialdif.com