Cellophane bags and cello bags are both transparent packaging options, but cellophane is made from cellulose, offering eco-friendliness and biodegradability, while cello bags are typically made from polypropylene, providing superior moisture resistance and durability. Cellophane bags are ideal for products needing breathability, such as baked goods or produce, whereas cello bags better protect items requiring longer shelf life or moisture barriers, like confectionery and flowers. Choosing between the two depends on product preservation needs and environmental considerations, with cellophane promoting sustainability and cello ensuring enhanced protection.

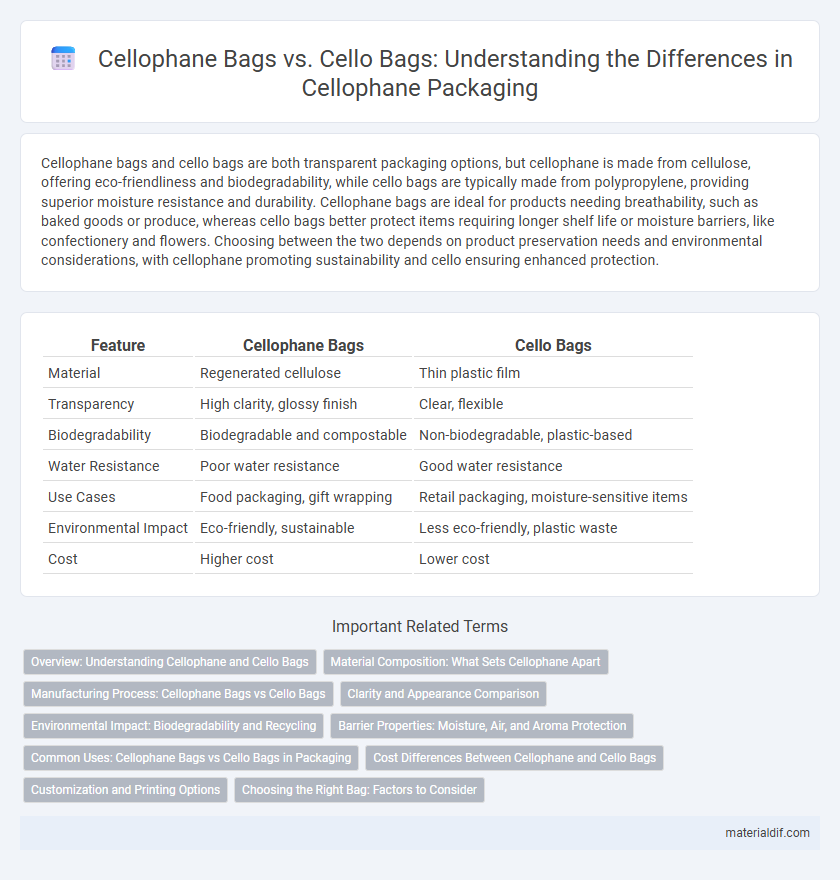

Table of Comparison

| Feature | Cellophane Bags | Cello Bags |

|---|---|---|

| Material | Regenerated cellulose | Thin plastic film |

| Transparency | High clarity, glossy finish | Clear, flexible |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, plastic-based |

| Water Resistance | Poor water resistance | Good water resistance |

| Use Cases | Food packaging, gift wrapping | Retail packaging, moisture-sensitive items |

| Environmental Impact | Eco-friendly, sustainable | Less eco-friendly, plastic waste |

| Cost | Higher cost | Lower cost |

Overview: Understanding Cellophane and Cello Bags

Cellophane bags are made from regenerated cellulose, a biodegradable and transparent material known for its moisture-resistant properties, making them ideal for food packaging. Cello bags, often a shorthand term for cellophane bags, typically refer to the same product but can sometimes denote slight variations in thickness or clarity depending on the manufacturer. Understanding the subtle differences and applications of cellophane versus cello bags helps businesses choose packaging solutions that optimize product visibility and environmental sustainability.

Material Composition: What Sets Cellophane Apart

Cellophane bags are crafted from regenerated cellulose derived from natural wood pulp, making them biodegradable and eco-friendly, whereas cello bags are typically made from polypropylene, a synthetic plastic. The cellulose material in cellophane offers superior breathability and moisture resistance compared to the non-breathable polypropylene of cello bags. This fundamental difference in material composition sets cellophane apart by providing a more sustainable and transparent packaging option that decomposes naturally over time.

Manufacturing Process: Cellophane Bags vs Cello Bags

Cellophane bags are produced from regenerated cellulose derived from wood pulp, involving a wet manufacturing process that creates a biodegradable, transparent film. Cello bags, often a shorthand for cellophane, are similarly made but may include blends with other materials or coatings for enhanced durability and water resistance. The key distinction lies in the manufacturing variations, where cellophane emphasizes natural cellulose composition, whereas cello bags may integrate synthetic modifications for specific packaging needs.

Clarity and Appearance Comparison

Cellophane bags offer superior clarity with a glass-like transparency that enhances product visibility, making them ideal for premium packaging. Cello bags, often made from thinner material, tend to have a slight haze that can dull the appearance of contents. The higher gloss and smooth surface of cellophane bags provide a more polished and professional look compared to the more matte finish of cello bags.

Environmental Impact: Biodegradability and Recycling

Cellophane bags are made from cellulose, a natural polymer derived from wood pulp, making them biodegradable and compostable in industrial facilities, which reduces their environmental footprint. In contrast, cello bags, typically made from polypropylene, are less biodegradable and rely heavily on recycling processes that are not always available or efficient in reducing plastic waste. Choosing cellophane bags over cello bags supports a more sustainable packaging option due to their enhanced biodegradability and compatibility with eco-friendly waste management systems.

Barrier Properties: Moisture, Air, and Aroma Protection

Cellophane bags offer superior moisture, air, and aroma barrier properties due to their dense cellulose film composition, which effectively preserves product freshness. Cello bags, often made from thinner or lower-grade materials, provide less reliable protection against external elements, making them less ideal for sensitive goods. Choosing cellophane bags ensures enhanced shelf life and maintained quality by preventing moisture ingress, oxygen exposure, and aroma loss.

Common Uses: Cellophane Bags vs Cello Bags in Packaging

Cellophane bags, made from regenerated cellulose, are widely used for packaging edible items like baked goods, candies, and produce due to their biodegradability and moisture resistance. Cello bags, a type of cellophane typically featuring a thinner and more flexible film, are preferred for lightweight items such as gift wrapping, small crafts, and party favors. Both packaging options provide clear visibility and protection but differ in durability and flexibility suited to specific product requirements.

Cost Differences Between Cellophane and Cello Bags

Cellophane bags generally cost more than cello bags due to their biodegradable cellulose composition, which involves a more complex manufacturing process compared to the cheaper, plastic-based cello bags. Cello bags benefit from lower production costs as they are made from polypropylene, making them a budget-friendly option for packaging. The cost difference becomes significant in large-scale purchases, where businesses choose cello bags to minimize expenses while still maintaining a clear, attractive presentation.

Customization and Printing Options

Cellophane bags offer a wide range of customization options including full-color printing, logo embossing, and variable sizes, making them ideal for personalized branding and product presentation. Cello bags generally provide fewer printing choices and are often limited to standard sizes and clear finishes, focusing more on affordability and simplicity. Businesses seeking unique design elements and vibrant graphics typically prefer cellophane bags for enhanced marketing impact.

Choosing the Right Bag: Factors to Consider

Choosing the right bag involves understanding the differences between cellophane bags and cello bags, both made from cellulose but varying in thickness and clarity. Cellophane bags offer eco-friendly, biodegradable options with excellent moisture resistance, ideal for packaging food and gifts that require breathability. Cello bags, typically thinner and more transparent, are better suited for decorative packaging where visual appeal and lightweight protection are priorities.

Cellophane Bags vs Cello Bags Infographic

materialdif.com

materialdif.com