Cellophane is a biodegradable film made from cellulose, offering excellent transparency and breathability compared to PLA (Polylactic Acid), which is a bioplastic derived from renewable resources like corn starch. While cellophane provides superior moisture resistance and is fully compostable, PLA tends to be more rigid and less permeable but is widely used for packaging due to its ease of processing. Both materials contribute to sustainable packaging solutions, with cellophane favored for natural fiber content and PLA for its compatibility with industrial composting.

Table of Comparison

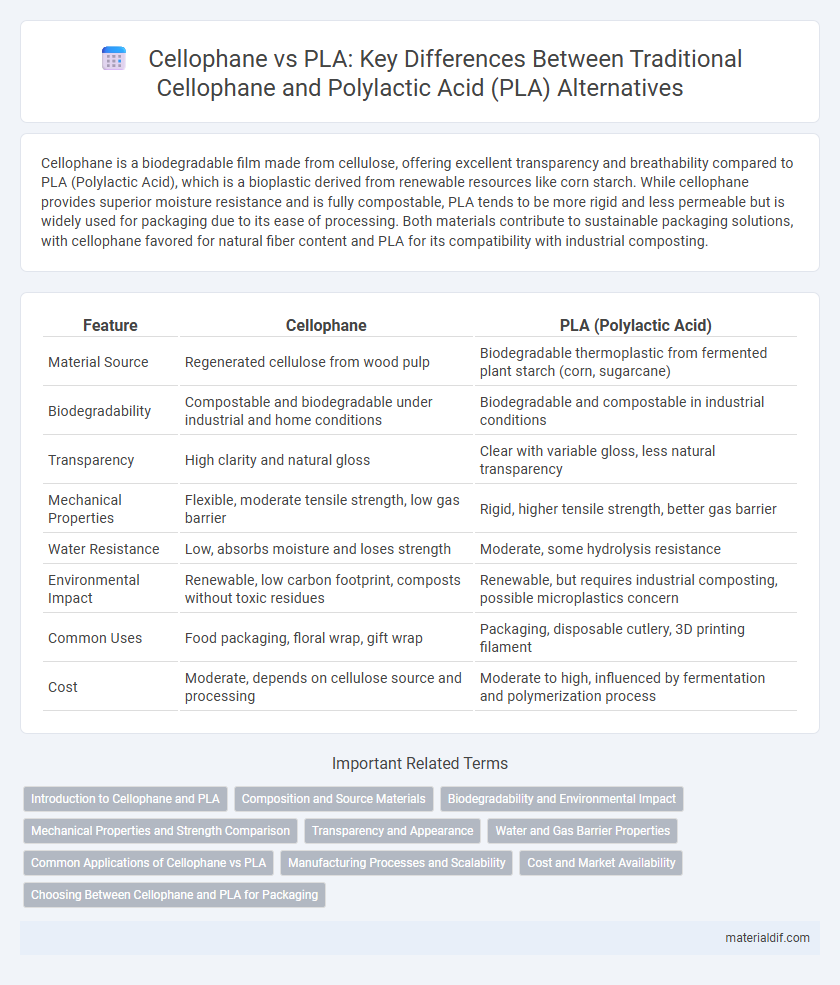

| Feature | Cellophane | PLA (Polylactic Acid) |

|---|---|---|

| Material Source | Regenerated cellulose from wood pulp | Biodegradable thermoplastic from fermented plant starch (corn, sugarcane) |

| Biodegradability | Compostable and biodegradable under industrial and home conditions | Biodegradable and compostable in industrial conditions |

| Transparency | High clarity and natural gloss | Clear with variable gloss, less natural transparency |

| Mechanical Properties | Flexible, moderate tensile strength, low gas barrier | Rigid, higher tensile strength, better gas barrier |

| Water Resistance | Low, absorbs moisture and loses strength | Moderate, some hydrolysis resistance |

| Environmental Impact | Renewable, low carbon footprint, composts without toxic residues | Renewable, but requires industrial composting, possible microplastics concern |

| Common Uses | Food packaging, floral wrap, gift wrap | Packaging, disposable cutlery, 3D printing filament |

| Cost | Moderate, depends on cellulose source and processing | Moderate to high, influenced by fermentation and polymerization process |

Introduction to Cellophane and PLA

Cellophane is a transparent, biodegradable film derived from cellulose, known for its excellent oxygen and aroma barrier properties, making it ideal for food packaging. PLA (Polylactic Acid) is a bio-based, compostable polymer made from renewable resources like corn starch, widely used for sustainable packaging and disposable items. Both materials serve as eco-friendly alternatives to traditional plastics but differ in origin, mechanical properties, and biodegradability conditions.

Composition and Source Materials

Cellophane is a thin, transparent film made from regenerated cellulose derived from wood pulp or cotton fibers, emphasizing its natural and biodegradable origin. In contrast, PLA (Polylactic Acid) is a bioplastic synthesized from fermented plant starches, primarily corn or sugarcane, offering a renewable and compostable alternative. Both materials are eco-friendly but differ fundamentally in their source and chemical composition; cellophane is a cellulose-based polymer, whereas PLA is a polyester derived from lactic acid monomers.

Biodegradability and Environmental Impact

Cellophane is a biodegradable film made from cellulose, which decomposes naturally in a few weeks under composting conditions, minimizing environmental pollution. PLA (Polylactic Acid), derived from renewable resources like corn starch, also biodegrades but often requires industrial composting facilities with specific temperature conditions to break down effectively. Both materials reduce plastic waste compared to conventional plastics, but cellophane's faster natural degradation offers a lower environmental impact in home composting scenarios.

Mechanical Properties and Strength Comparison

Cellophane exhibits high tensile strength and excellent flexibility, making it resistant to tearing under stress, while PLA (Polylactic Acid) offers greater rigidity but lower elongation at break. PLA's mechanical strength includes a higher modulus of elasticity, providing sturdiness in structural applications, whereas cellophane's mechanical properties favor applications requiring transparency and flexibility. Comparative analysis shows cellophane excels in flexibility and moisture barrier performance, but PLA outperforms cellophane in load-bearing capacity and thermal resistance.

Transparency and Appearance

Cellophane offers superior clarity and a natural glossy finish, making it highly transparent and ideal for showcasing product appearance. In comparison, PLA (Polylactic Acid) tends to have a more matte and slightly opaque surface, which can reduce the overall visibility of packaged goods. The inherent transparency of cellophane enhances visual appeal, while PLA may require additional treatments to achieve similar clarity.

Water and Gas Barrier Properties

Cellophane offers superior gas barrier properties compared to PLA (Polylactic Acid), effectively limiting oxygen and carbon dioxide transmission, which enhances food preservation. However, PLA demonstrates better water vapor resistance than cellophane, making it more suitable for applications requiring moisture protection. The choice between cellophane and PLA depends on the specific barrier requirements for water vapor and gases in packaging applications.

Common Applications of Cellophane vs PLA

Cellophane is widely used for food packaging, gift wrapping, and floral wrapping due to its moisture barrier and biodegradability, making it ideal for preserving freshness. PLA (Polylactic Acid) is primarily applied in compostable packaging, disposable tableware, and 3D printing materials because of its renewable source and biodegradability under industrial composting conditions. Both materials serve sustainable packaging needs but differ as cellophane excels in moisture resistance while PLA is favored for rigid and molded products.

Manufacturing Processes and Scalability

Cellophane is produced through the viscose process, involving cellulose extraction from wood pulp, xanthation, and regeneration into thin films, which requires extensive chemical treatments and energy consumption. PLA (Polylactic Acid) manufacturing relies on fermentation of renewable resources like corn starch, followed by polymerization, enabling a more sustainable and potentially scalable bioplastic production. Scalability of PLA benefits from agricultural feedstock availability and established biorefinery infrastructure, whereas cellophane production faces limitations due to complex chemical processes and environmental regulations.

Cost and Market Availability

Cellophane offers a cost-effective packaging solution compared to PLA, with lower raw material and production expenses driving its affordability. Market availability favors cellophane due to its established supply chains and widespread use in food packaging and retail industries. PLA, while biodegradable, faces higher costs and limited distribution, constraining its adoption beyond niche eco-friendly markets.

Choosing Between Cellophane and PLA for Packaging

Cellophane offers superior breathability and moisture resistance compared to PLA, making it ideal for packaging fresh produce and perishable items. PLA, a biodegradable bioplastic derived from renewable resources, excels in rigid packaging and provides better heat resistance for microwavable containers. Choosing between cellophane and PLA depends on the specific packaging requirements, such as flexibility, compostability, and barrier properties.

Cellophane vs PLA (Polylactic Acid) Infographic

materialdif.com

materialdif.com