Cellophane and PET film differ significantly in material composition and application. Cellophane, made from regenerated cellulose, is biodegradable and offers excellent breathability, making it ideal for food wrapping that requires moisture control. PET film, a type of polyester, provides superior strength, clarity, and moisture resistance, commonly used in industrial packaging and durable product wrapping.

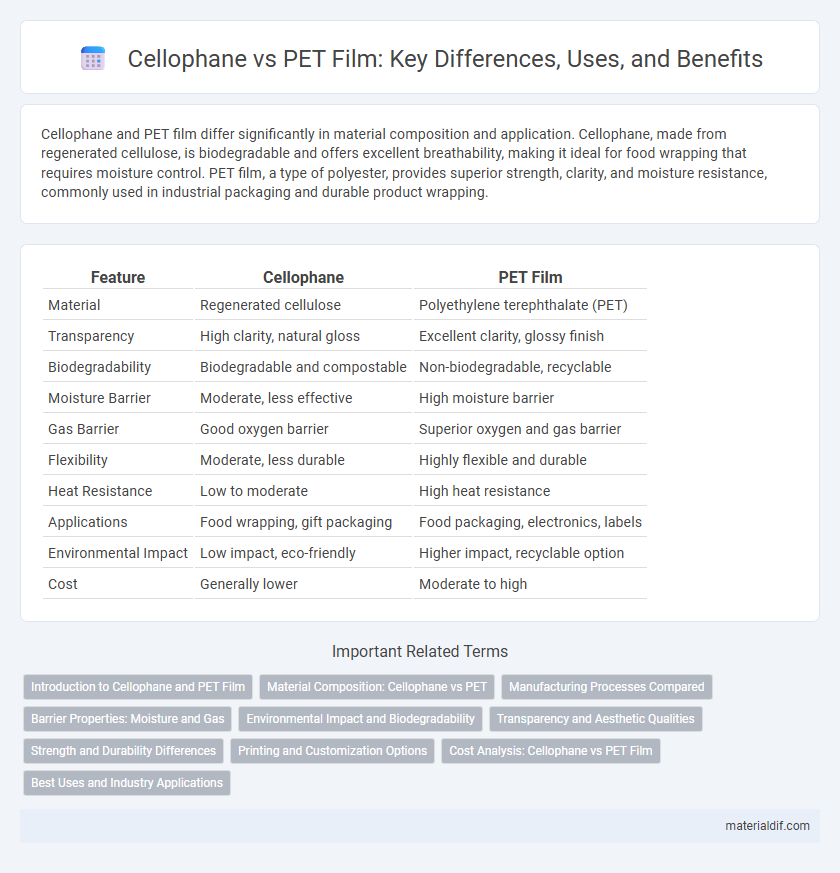

Table of Comparison

| Feature | Cellophane | PET Film |

|---|---|---|

| Material | Regenerated cellulose | Polyethylene terephthalate (PET) |

| Transparency | High clarity, natural gloss | Excellent clarity, glossy finish |

| Biodegradability | Biodegradable and compostable | Non-biodegradable, recyclable |

| Moisture Barrier | Moderate, less effective | High moisture barrier |

| Gas Barrier | Good oxygen barrier | Superior oxygen and gas barrier |

| Flexibility | Moderate, less durable | Highly flexible and durable |

| Heat Resistance | Low to moderate | High heat resistance |

| Applications | Food wrapping, gift packaging | Food packaging, electronics, labels |

| Environmental Impact | Low impact, eco-friendly | Higher impact, recyclable option |

| Cost | Generally lower | Moderate to high |

Introduction to Cellophane and PET Film

Cellophane, a thin, transparent sheet made from regenerated cellulose, offers biodegradability and excellent gas permeability ideal for food packaging. PET film, or polyethylene terephthalate, is a durable, synthetic polymer known for its superior strength, moisture resistance, and clarity in packaging applications. Both materials serve as versatile films, but cellophane emphasizes eco-friendliness while PET film prioritizes mechanical robustness.

Material Composition: Cellophane vs PET

Cellophane is derived from regenerated cellulose, a natural polymer sourced from wood pulp or cotton fibers, making it biodegradable and breathable. PET film, or polyethylene terephthalate, is a synthetic polyester created through polymerization of ethylene glycol and terephthalic acid, known for its durability, moisture resistance, and clarity. The distinct material compositions result in cellophane's environmental friendliness and PET's superior mechanical strength and barrier properties.

Manufacturing Processes Compared

Cellophane is produced through a process of cellulose extraction from wood pulp, followed by regeneration and plasticization to create a thin, transparent film, whereas PET film is manufactured by polymerizing ethylene glycol and terephthalic acid into polyethylene terephthalate polymer, which is then extruded and biaxially oriented for strength and clarity. The cellophane production relies heavily on chemical treatment and biodegradable raw materials, making it more environmentally friendly but less durable compared to PET film, which involves synthetic polymers and energy-intensive processes. PET's extrusion and stretching methods yield films with superior tensile strength, heat resistance, and barrier properties, differentiating its manufacturing complexity from the cellulose-based cellophane process.

Barrier Properties: Moisture and Gas

Cellophane exhibits superior moisture barrier properties compared to PET film, making it ideal for packaging products sensitive to humidity. However, PET film generally provides better gas barrier performance, particularly against oxygen and carbon dioxide, which extends the shelf life of perishable goods. The choice between cellophane and PET film depends on the specific moisture and gas barrier requirements of the packaged product.

Environmental Impact and Biodegradability

Cellophane is a biodegradable material derived from cellulose, offering a significantly lower environmental impact compared to PET film, which is petroleum-based and non-biodegradable. Unlike PET, cellophane breaks down naturally in composting environments without releasing harmful microplastics, reducing landfill waste and pollution. The renewable sourcing and compostability of cellophane make it a more sustainable choice for packaging applications requiring environmental responsibility.

Transparency and Aesthetic Qualities

Cellophane offers superior natural transparency and a glossy finish that enhances product visibility and shelf appeal, making it ideal for premium packaging applications. PET film, while also transparent, typically provides higher clarity with enhanced resistance to moisture and chemicals, contributing to a more durable and long-lasting aesthetic. The choice between cellophane and PET film hinges on the desired balance between natural biodegradability and synthetic durability in packaging design.

Strength and Durability Differences

Cellophane offers moderate strength and biodegradability, but PET film surpasses it significantly in tensile strength and tear resistance, making PET ideal for heavy-duty packaging applications. PET film's superior durability provides enhanced protection against moisture, chemicals, and UV exposure, extending product shelf life compared to cellophane. While cellophane's biodegradable nature is advantageous for environmental sustainability, PET film's robustness ensures greater performance in demanding industrial uses.

Printing and Customization Options

Cellophane offers superior printing clarity due to its natural cellulose base, enabling vibrant, high-resolution graphics with excellent ink adhesion. PET film provides more flexibility in printing techniques, supporting various finishes such as matte, gloss, and metallic effects, suitable for premium packaging designs. Customization on cellophane is limited to fewer coatings and surface treatments, whereas PET films support extensive customization options including lamination, embossing, and multi-layer printing for enhanced durability and visual impact.

Cost Analysis: Cellophane vs PET Film

Cellophane generally offers a lower initial material cost compared to PET film, making it a cost-effective choice for packaging applications with moderate durability requirements. However, PET film provides superior strength, barrier properties, and longer lifespan, potentially reducing overall costs through decreased product damage and extended shelf life. When analyzing total cost, factors such as production volume, storage conditions, and end-use durability must be considered to determine the most economical option between cellophane and PET film.

Best Uses and Industry Applications

Cellophane excels in food packaging due to its excellent breathability and biodegradability, making it ideal for fresh produce, bakery items, and confectionery where moisture control and environmental sustainability are priorities. PET film offers superior strength, clarity, and moisture barrier properties, widely used in beverage labels, flexible packaging, and electronic displays requiring durability and high tensile strength. Industries favor cellophane for eco-friendly applications in pharmaceuticals and retail packaging, while PET dominates automotive, electronics, and food packaging sectors demanding robustness and extended shelf life.

Cellophane vs Pet Film Infographic

materialdif.com

materialdif.com