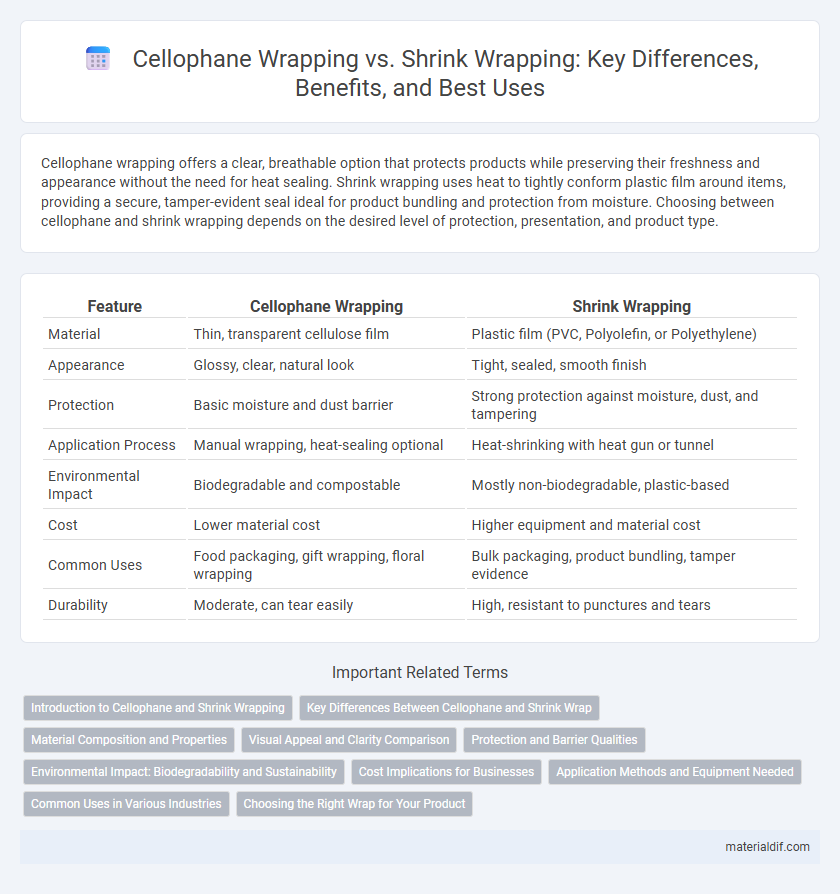

Cellophane wrapping offers a clear, breathable option that protects products while preserving their freshness and appearance without the need for heat sealing. Shrink wrapping uses heat to tightly conform plastic film around items, providing a secure, tamper-evident seal ideal for product bundling and protection from moisture. Choosing between cellophane and shrink wrapping depends on the desired level of protection, presentation, and product type.

Table of Comparison

| Feature | Cellophane Wrapping | Shrink Wrapping |

|---|---|---|

| Material | Thin, transparent cellulose film | Plastic film (PVC, Polyolefin, or Polyethylene) |

| Appearance | Glossy, clear, natural look | Tight, sealed, smooth finish |

| Protection | Basic moisture and dust barrier | Strong protection against moisture, dust, and tampering |

| Application Process | Manual wrapping, heat-sealing optional | Heat-shrinking with heat gun or tunnel |

| Environmental Impact | Biodegradable and compostable | Mostly non-biodegradable, plastic-based |

| Cost | Lower material cost | Higher equipment and material cost |

| Common Uses | Food packaging, gift wrapping, floral wrapping | Bulk packaging, product bundling, tamper evidence |

| Durability | Moderate, can tear easily | High, resistant to punctures and tears |

Introduction to Cellophane and Shrink Wrapping

Cellophane is a transparent film made from regenerated cellulose, known for its breathability and biodegradability, commonly used for packaging delicate items like food and gifts. Shrink wrapping involves using heat to tightly enclose products with a plastic film, providing a secure and tamper-evident seal, whereas cellophane wrapping typically offers a looser, more decorative cover. Both methods protect products but differ significantly in material composition and application techniques.

Key Differences Between Cellophane and Shrink Wrap

Cellophane is a transparent, biodegradable film made from cellulose, known for its breathability and moisture resistance, commonly used for wrapping food and gifts. Shrink wrap, typically made from polyolefin or PVC, tightens around items when heated, providing a secure, tamper-evident seal ideal for packaging and shipping. The key differences lie in material composition, environmental impact, and the application process--cellophane wraps use tension and adhesion, while shrink wrap requires heat to conform tightly around objects.

Material Composition and Properties

Cellophane wrapping is made from regenerated cellulose derived from wood pulp, making it biodegradable, breathable, and moisture-resistant, ideal for packaging fresh produce and confectionery. Shrink wrapping typically uses polyethylene or polyolefin plastics, which provide a tight, conforming seal when heat is applied, offering superior protection against contamination and tampering. The key difference lies in cellophane's natural, eco-friendly composition compared to shrink wrap's synthetic polymers, influencing their respective barrier properties and environmental impact.

Visual Appeal and Clarity Comparison

Cellophane wrapping offers superior visual appeal due to its natural gloss and transparent finish, enhancing product presentation with a crisp, polished look. In contrast, shrink wrapping provides a tighter, contour-hugging fit that can sometimes create wrinkles or cloudiness, reducing overall clarity. For products where clear visibility and an attractive, smooth surface are priorities, cellophane excels in showcasing items with vibrant, undistorted visuals.

Protection and Barrier Qualities

Cellophane wrapping provides excellent breathability and moisture resistance, making it ideal for products needing a natural barrier against external contaminants while allowing some air exchange. Shrink wrapping, using heat to tightly conform to the product, offers superior protection against punctures, tampering, and environmental factors by creating a durable, sealed barrier. The choice between cellophane and shrink wrapping hinges on the desired balance between breathability and robust, puncture-resistant protection.

Environmental Impact: Biodegradability and Sustainability

Cellophane wrapping, derived from cellulose, is biodegradable and compostable, making it a more environmentally sustainable option compared to shrink wrapping, which is typically made from petroleum-based plastics that persist in landfills. The production of cellophane uses renewable resources and results in a lower carbon footprint, contributing to reduced environmental impact. Shrink wrapping's reliance on non-biodegradable polymers often leads to increased plastic pollution and challenges in recycling, further diminishing its sustainability profile.

Cost Implications for Businesses

Cellophane wrapping generally incurs lower upfront costs due to its simpler application process and minimal equipment requirements, making it suitable for small businesses or low-volume packaging. Shrink wrapping, while involving higher initial investment in heat tunnels and machinery, offers tighter seals and better product protection that can reduce damage-related costs over time. Businesses must weigh the cost-effectiveness of cellophane's affordability against shrink wrapping's potential savings from enhanced durability and shelf appeal.

Application Methods and Equipment Needed

Cellophane wrapping involves manually wrapping products with a thin, transparent cellulose film using simple tools like heat sealers or adhesive tapes, ideal for delicate items and small-scale operations. Shrink wrapping requires specialized heat tunnels or chambers that apply controlled heat to shrink plastic film tightly around products, offering a more secure and tamper-evident seal suited for bulk packaging. The choice between methods depends on product sensitivity, production volume, and desired packaging durability.

Common Uses in Various Industries

Cellophane wrapping is widely used in the food industry for packaging bakery items, confectionery, and fresh produce due to its breathability and moisture resistance. Shrink wrapping is preferred in electronics, pharmaceuticals, and retail sectors for secure, tamper-evident packaging that offers tight protection and enhanced shelf appeal. Both methods serve distinct purposes in packaging with cellophane offering biodegradability advantages, while shrink wrapping provides superior mechanical protection.

Choosing the Right Wrap for Your Product

Cellophane wrapping offers a breathable, biodegradable option ideal for products requiring moisture control and visibility, such as baked goods and fresh produce. Shrink wrapping provides a tight, secure seal that protects against tampering, dust, and moisture, making it suitable for electronics, DVDs, and bulk packaging. Selecting the right wrap depends on product sensitivity, shelf life, and presentation needs, with cellophane excelling in eco-friendly appeal and shrink wrap delivering superior durability.

Cellophane Wrapping vs Shrink Wrapping Infographic

materialdif.com

materialdif.com