Cellophane PET offers an excellent moisture barrier, preventing water vapor from compromising product quality during storage. While it provides some protection against oxygen, its oxygen barrier properties are generally less effective compared to specialized materials like EVOH or metallized films. Choosing Cellophane PET is ideal when moisture resistance is critical, but additional layers may be needed for enhanced oxygen barrier performance.

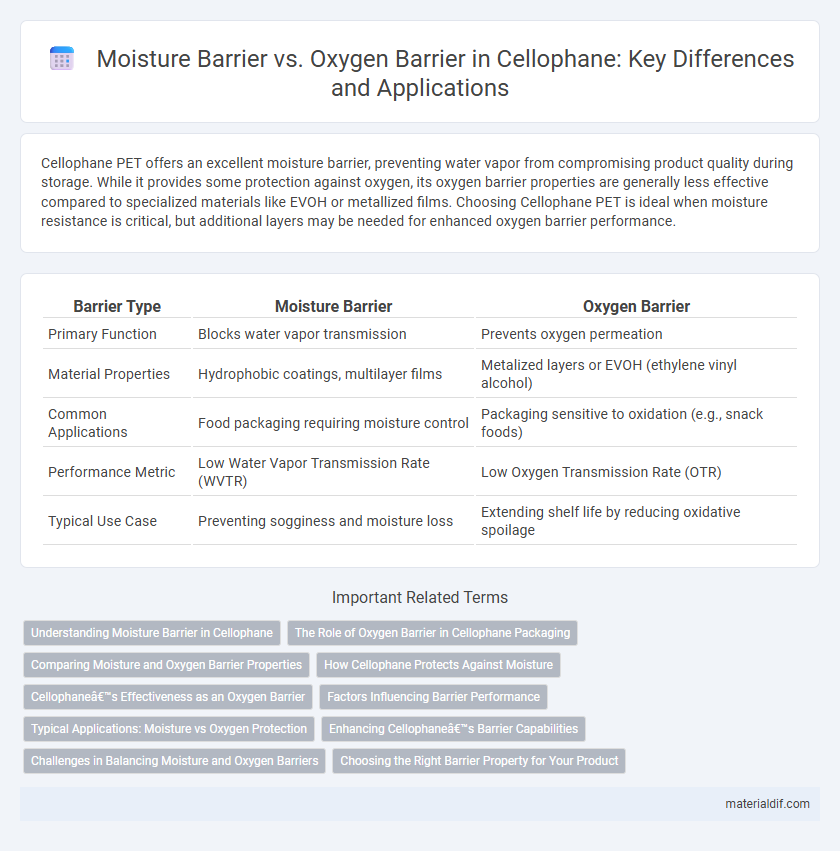

Table of Comparison

| Barrier Type | Moisture Barrier | Oxygen Barrier |

|---|---|---|

| Primary Function | Blocks water vapor transmission | Prevents oxygen permeation |

| Material Properties | Hydrophobic coatings, multilayer films | Metalized layers or EVOH (ethylene vinyl alcohol) |

| Common Applications | Food packaging requiring moisture control | Packaging sensitive to oxidation (e.g., snack foods) |

| Performance Metric | Low Water Vapor Transmission Rate (WVTR) | Low Oxygen Transmission Rate (OTR) |

| Typical Use Case | Preventing sogginess and moisture loss | Extending shelf life by reducing oxidative spoilage |

Understanding Moisture Barrier in Cellophane

Moisture barrier properties in cellophane are critical for protecting products from humidity and maintaining freshness by preventing water vapor transmission. This barrier is achieved through specialized coatings or laminations that reduce permeability and enhance the film's resistance to moisture absorption. Understanding the moisture barrier function is essential for applications in food packaging, where controlling moisture levels directly impacts shelf life and product quality.

The Role of Oxygen Barrier in Cellophane Packaging

The oxygen barrier property in cellophane packaging plays a critical role in preserving product freshness by preventing oxygen permeation, which can cause spoilage and degradation. Unlike moisture barriers that primarily control water vapor transmission, the oxygen barrier ensures the chemical stability of oxygen-sensitive goods such as food, pharmaceuticals, and electronics. Enhanced oxygen barrier cellophane films extend shelf life and maintain product quality by minimizing oxidative reactions.

Comparing Moisture and Oxygen Barrier Properties

Cellophane exhibits excellent oxygen barrier properties, effectively preventing oxygen transmission and preserving product freshness, but it has moderate moisture barrier capabilities, making it less effective against water vapor. Compared to other packaging materials, cellophane's oxygen barrier performance is superior, while its moisture resistance is typically enhanced through coatings or laminations to improve protection. Understanding these differences is crucial for selecting cellophane in applications requiring either oxygen sensitivity or moisture control.

How Cellophane Protects Against Moisture

Cellophane exhibits excellent moisture barrier properties due to its ability to resist water vapor transmission, making it highly effective for packaging applications that require protection against humidity. Its dense cellulose structure significantly reduces moisture permeation, thereby preserving the quality and shelf life of food products. Compared to oxygen barriers, cellophane's primary advantage lies in its superior moisture resistance, preventing spoilage and maintaining product freshness.

Cellophane’s Effectiveness as an Oxygen Barrier

Cellophane exhibits excellent oxygen barrier properties, making it highly effective for packaging applications requiring protection from oxidation and spoilage. Its dense molecular structure limits oxygen permeability better than many moisture barrier materials, though it is less effective at blocking water vapor. This oxygen impermeability enhances shelf life and preserves the freshness of products like food and pharmaceuticals.

Factors Influencing Barrier Performance

Moisture barrier and oxygen barrier performance in cellophane depend on factors such as film thickness, crystallinity, and surface treatment methods like coating or lamination. Environmental conditions, including relative humidity and temperature, significantly impact barrier effectiveness by altering the polymer structure and permeability. Chemical composition and molecular orientation also play critical roles in determining the selective permeability to water vapor versus oxygen gases.

Typical Applications: Moisture vs Oxygen Protection

Cellophane excels as a moisture barrier, making it ideal for packaging foods that require protection from humidity, such as fresh produce, baked goods, and confectionery. Oxygen barrier properties are crucial for applications like snack foods, dried fruits, and pharmaceutical products, where oxygen exposure can degrade quality and shelf life. Choosing cellophane with the appropriate barrier characteristics ensures optimal preservation and freshness tailored to specific product needs.

Enhancing Cellophane’s Barrier Capabilities

Enhancing cellophane's barrier capabilities involves improving its resistance to moisture and oxygen, critical for preserving product freshness and extending shelf life. Moisture barriers prevent the passage of water vapor, essential for products sensitive to humidity, while oxygen barriers inhibit oxidative spoilage and maintain aroma integrity. Advanced treatments and coatings such as nitrocellulose or PVDC significantly enhance cellophane's barrier properties, making it suitable for diverse packaging applications.

Challenges in Balancing Moisture and Oxygen Barriers

Achieving an optimal balance between moisture barrier and oxygen barrier properties in cellophane packaging poses significant challenges due to their conflicting material characteristics. Enhancing moisture resistance typically compromises oxygen permeability, while improving oxygen barrier often increases moisture transmission, complicating the preservation of sensitive products. Advanced coatings and multilayer structures are crucial solutions in cellophane production to address this delicate trade-off effectively.

Choosing the Right Barrier Property for Your Product

Moisture barrier and oxygen barrier properties play critical roles in preserving product quality, with moisture barriers preventing water vapor transmission and oxygen barriers blocking oxygen ingress. Selecting the right barrier depends on the product's sensitivity; for example, food items prone to spoilage require strong oxygen barriers to extend shelf life, while products susceptible to moisture damage need effective moisture barriers. Cellophane's natural ability to provide excellent moisture resistance combined with enhanced oxygen barrier coatings makes it a versatile choice for tailored packaging solutions.

Moisture Barrier vs Oxygen Barrier Infographic

materialdif.com

materialdif.com