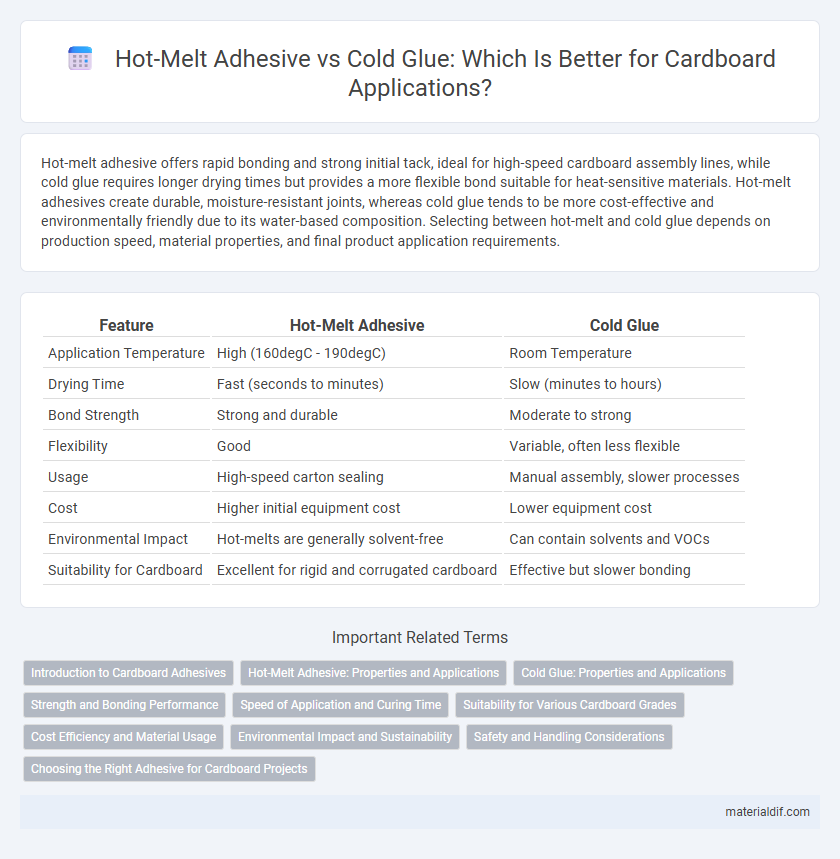

Hot-melt adhesive offers rapid bonding and strong initial tack, ideal for high-speed cardboard assembly lines, while cold glue requires longer drying times but provides a more flexible bond suitable for heat-sensitive materials. Hot-melt adhesives create durable, moisture-resistant joints, whereas cold glue tends to be more cost-effective and environmentally friendly due to its water-based composition. Selecting between hot-melt and cold glue depends on production speed, material properties, and final product application requirements.

Table of Comparison

| Feature | Hot-Melt Adhesive | Cold Glue |

|---|---|---|

| Application Temperature | High (160degC - 190degC) | Room Temperature |

| Drying Time | Fast (seconds to minutes) | Slow (minutes to hours) |

| Bond Strength | Strong and durable | Moderate to strong |

| Flexibility | Good | Variable, often less flexible |

| Usage | High-speed carton sealing | Manual assembly, slower processes |

| Cost | Higher initial equipment cost | Lower equipment cost |

| Environmental Impact | Hot-melts are generally solvent-free | Can contain solvents and VOCs |

| Suitability for Cardboard | Excellent for rigid and corrugated cardboard | Effective but slower bonding |

Introduction to Cardboard Adhesives

Hot-melt adhesives provide rapid bonding and strong initial tack, making them ideal for high-speed cardboard packaging lines. Cold glues, typically water-based, offer durable, flexible bonds that are resistant to environmental factors but require longer curing times. Choosing the appropriate adhesive depends on factors such as production speed, bonding strength, and carton end-use conditions.

Hot-Melt Adhesive: Properties and Applications

Hot-melt adhesive offers fast bonding and strong adhesion on cardboard, enabling rapid packaging and assembly operations without drying time. Its thermoplastic properties provide excellent resistance to moisture and temperature variations, making it ideal for durable and flexible cardboard products. Common applications include carton sealing, lamination, and product packaging requiring quick set times and high bond strength.

Cold Glue: Properties and Applications

Cold glue, also known as water-based adhesive, offers strong initial tack and flexible bonding ideal for cardboard packaging and corrugated boxes. Its quick drying time and easy clean-up make it suitable for high-speed production lines in industries such as food packaging and shipping. The adhesive's environmental friendliness, non-toxicity, and resistance to temperature fluctuations ensure durable and safe product assembly.

Strength and Bonding Performance

Hot-melt adhesive offers rapid bonding with high initial strength, ideal for fast production lines requiring immediate handling of cardboard. Cold glue provides stronger long-term adhesion by penetrating fibers deeply, ensuring durable bonds for heavier or moisture-sensitive cardboard applications. Both adhesives excel in different aspects of strength and bonding performance, with hot-melt favored for speed and cold glue preferred for lasting durability.

Speed of Application and Curing Time

Hot-melt adhesive offers rapid application and curing times, typically setting within seconds, making it ideal for high-speed cardboard assembly lines. Cold glue requires longer drying periods, often ranging from several minutes to hours, which can slow production but provides strong, durable bonds when fully cured. Choosing between these adhesives depends on balancing the need for speed against bond strength and production workflow efficiency.

Suitability for Various Cardboard Grades

Hot-melt adhesive offers superior bonding strength for thicker, multi-layered cardboard grades such as corrugated fiberboard, ensuring durability in packaging applications. Cold glue works effectively on lightweight, single-ply cardboard like folding cartons, providing flexibility and slower setting times suited for delicate materials. Selecting between hot-melt and cold glue depends on the cardboard's thickness, porosity, and desired production speed, optimizing adhesion and performance.

Cost Efficiency and Material Usage

Hot-melt adhesive offers higher cost efficiency in cardboard manufacturing by reducing drying time and minimizing downtime, leading to faster production rates. Cold glue uses more adhesive per bond and requires longer curing periods, increasing material consumption and operational costs. Manufacturers prefer hot-melt adhesives for high-volume runs due to lower waste and improved adhesive performance on recycled or corrugated cardboard.

Environmental Impact and Sustainability

Hot-melt adhesives used in cardboard packaging are typically solvent-free and have low VOC emissions, reducing environmental pollution compared to solvent-based adhesives. Cold glues often contain water-based formulations that are biodegradable and more environmentally friendly, but may require longer drying times and energy for curing. Choosing between hot-melt and cold glue depends on balancing sustainability goals with production efficiency and recyclability of the cardboard materials.

Safety and Handling Considerations

Hot-melt adhesive requires handling at high temperatures, posing burn risks and necessitating protective equipment and proper ventilation, while cold glue is generally safer to handle due to its low-temperature application and minimal toxic emissions. Cold glue offers easier cleanup and less stringent storage conditions compared to hot-melt adhesives, which solidify quickly and require consistent heating to maintain usability. Safety protocols for hot-melt adhesives must emphasize temperature control and handling training, whereas cold glue prioritizes non-toxicity and safe disposal practices.

Choosing the Right Adhesive for Cardboard Projects

Hot-melt adhesive offers rapid bonding and strong initial tack, making it ideal for high-speed cardboard assembly lines where quick set times are essential. Cold glue provides superior flexibility and water resistance, enhancing durability for packaging that requires longer drying times and exposure to moisture. Selecting the right adhesive depends on project speed, environmental conditions, and the desired strength of the cardboard bond.

Hot-melt adhesive vs Cold glue Infographic

materialdif.com

materialdif.com