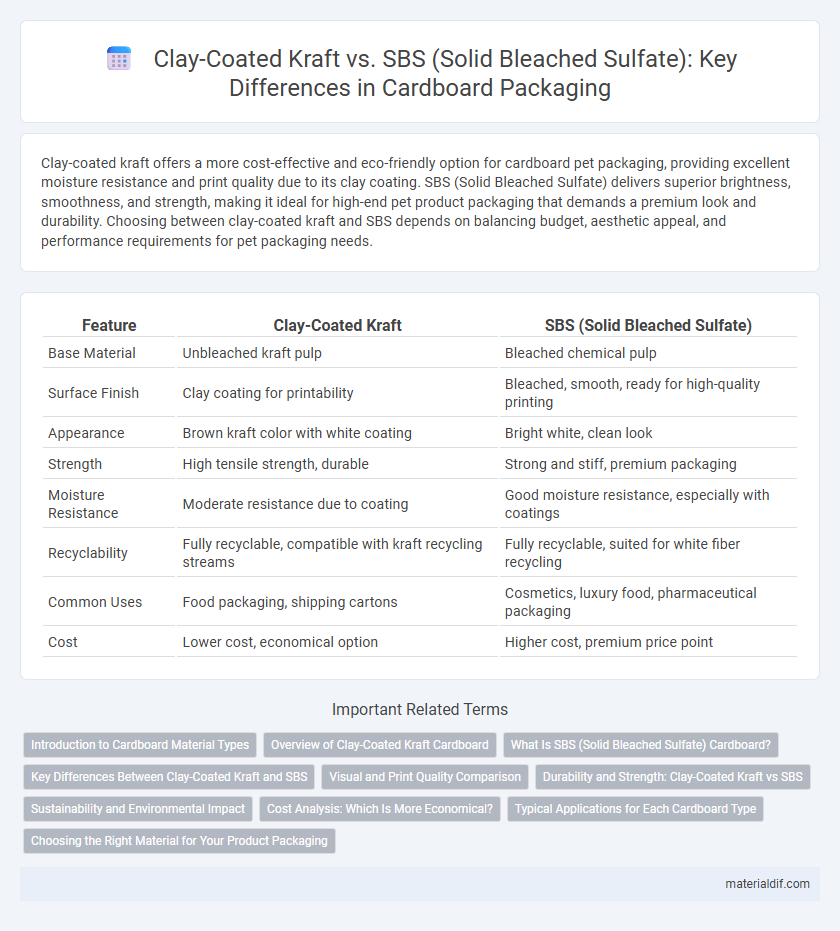

Clay-coated kraft offers a more cost-effective and eco-friendly option for cardboard pet packaging, providing excellent moisture resistance and print quality due to its clay coating. SBS (Solid Bleached Sulfate) delivers superior brightness, smoothness, and strength, making it ideal for high-end pet product packaging that demands a premium look and durability. Choosing between clay-coated kraft and SBS depends on balancing budget, aesthetic appeal, and performance requirements for pet packaging needs.

Table of Comparison

| Feature | Clay-Coated Kraft | SBS (Solid Bleached Sulfate) |

|---|---|---|

| Base Material | Unbleached kraft pulp | Bleached chemical pulp |

| Surface Finish | Clay coating for printability | Bleached, smooth, ready for high-quality printing |

| Appearance | Brown kraft color with white coating | Bright white, clean look |

| Strength | High tensile strength, durable | Strong and stiff, premium packaging |

| Moisture Resistance | Moderate resistance due to coating | Good moisture resistance, especially with coatings |

| Recyclability | Fully recyclable, compatible with kraft recycling streams | Fully recyclable, suited for white fiber recycling |

| Common Uses | Food packaging, shipping cartons | Cosmetics, luxury food, pharmaceutical packaging |

| Cost | Lower cost, economical option | Higher cost, premium price point |

Introduction to Cardboard Material Types

Clay-coated kraft offers a durable and moisture-resistant surface ideal for packaging that requires strength and printability, combining recycled fibers with a smooth clay coating. SBS (Solid Bleached Sulfate) is a premium cardboard made from bleached virgin fibers, providing superior whiteness, stiffness, and an excellent printing surface for high-quality graphics. Both materials serve distinct packaging needs, with clay-coated kraft favored for everyday consumer goods and SBS preferred for luxury product packaging.

Overview of Clay-Coated Kraft Cardboard

Clay-coated kraft cardboard features a strong kraft paper base with a smooth, glossy clay coating that enhances print quality and provides excellent barrier properties. This material offers superior durability and moisture resistance, making it ideal for packaging applications requiring high-quality graphics and protection. Compared to SBS (Solid Bleached Sulfate), clay-coated kraft is more cost-effective while maintaining good stiffness and printability.

What Is SBS (Solid Bleached Sulfate) Cardboard?

SBS (Solid Bleached Sulfate) cardboard is a premium, high-quality paperboard made from bleached virgin wood pulp, known for its bright white appearance and smooth surface ideal for high-end packaging. Unlike clay-coated kraft, which combines recycled fibers with a clay coating for printability, SBS offers superior rigidity, cleanliness, and print clarity, making it the preferred choice for luxury brands and food-safe packaging. SBS cardboard is recyclable and often used for cosmetics, pharmaceuticals, and confectionery packaging due to its excellent strength and aesthetic qualities.

Key Differences Between Clay-Coated Kraft and SBS

Clay-coated kraft features a natural brown kraft base with a smooth, white, clay-coated surface providing excellent printability and cost efficiency for packaging. SBS (Solid Bleached Sulfate) is made from bleached virgin pulp, offering superior whiteness, stiffness, and purity suitable for high-end graphics and premium products. The key differences lie in their fiber sources, surface finish, and application suitability, with clay-coated kraft being more eco-friendly and SBS offering a higher-quality aesthetic.

Visual and Print Quality Comparison

Clay-coated kraft offers a smooth surface with moderate brightness, providing decent print quality suitable for packaging that requires durability combined with aesthetic appeal. SBS (Solid Bleached Sulfate) features a high-gloss, bright white surface that delivers superior visual clarity and sharpness in printing, ideal for premium packaging applications demanding vivid colors and fine detail. SBS's uniform texture enables more consistent ink absorption and sharper graphics compared to the slightly more textured finish of clay-coated kraft.

Durability and Strength: Clay-Coated Kraft vs SBS

Clay-coated kraft offers superior durability and moisture resistance due to its thick, fiber-rich structure combined with a clay coating that enhances surface smoothness and printability. SBS (Solid Bleached Sulfate) features high tensile strength and a pure white, uniform appearance, making it ideal for premium packaging that requires both strength and aesthetic appeal. When comparing durability, clay-coated kraft tends to withstand rough handling and moisture better, while SBS excels in stiffness and tear resistance for luxury product protection.

Sustainability and Environmental Impact

Clay-coated kraft paper combines recycled fibers with a clay coating to enhance printability and moisture resistance, offering a more sustainable option by utilizing post-consumer waste and reducing deforestation. SBS (Solid Bleached Sulfate) is made from virgin wood pulp, providing superior whiteness and strength but involving higher energy consumption and environmental impact due to intensive chemical bleaching and fewer recycled materials. Choosing clay-coated kraft over SBS can significantly reduce carbon footprint and resource depletion, aligning better with eco-friendly packaging and sustainability goals.

Cost Analysis: Which Is More Economical?

Clay-coated kraft paper typically offers a more cost-effective solution compared to Solid Bleached Sulfate (SBS) due to its lower raw material and production expenses, making it ideal for budget-conscious packaging needs. SBS, made from fully bleached chemical pulp, commands higher prices but delivers superior printability and whiteness, justifying its cost for premium branding applications. When evaluating total costs, including material, processing, and finishing, clay-coated kraft generally provides savings of 15-25% over SBS, influencing the choice for large-scale, cost-sensitive packaging projects.

Typical Applications for Each Cardboard Type

Clay-coated kraft paper is commonly used in packaging for food products, frozen goods, and retail shopping bags due to its grease resistance and high print quality. SBS (Solid Bleached Sulfate) cardboard excels in pharmaceutical packaging, cosmetics boxes, and high-end consumer goods packaging, offering superior whiteness and strength for premium presentation. Both materials provide excellent printability but serve distinct markets based on their structural and aesthetic properties.

Choosing the Right Material for Your Product Packaging

Clay-coated kraft offers excellent moisture resistance and a natural, earthy appearance ideal for eco-friendly packaging, while SBS (Solid Bleached Sulfate) provides superior strength, whiteness, and smoothness suitable for premium product presentation. Selecting the appropriate material depends on your product's protection requirements, desired aesthetic appeal, and budget constraints. Consider the trade-offs between sustainability and print quality to optimize packaging performance and brand impact.

Clay-coated kraft vs SBS (Solid Bleached Sulfate) Infographic

materialdif.com

materialdif.com