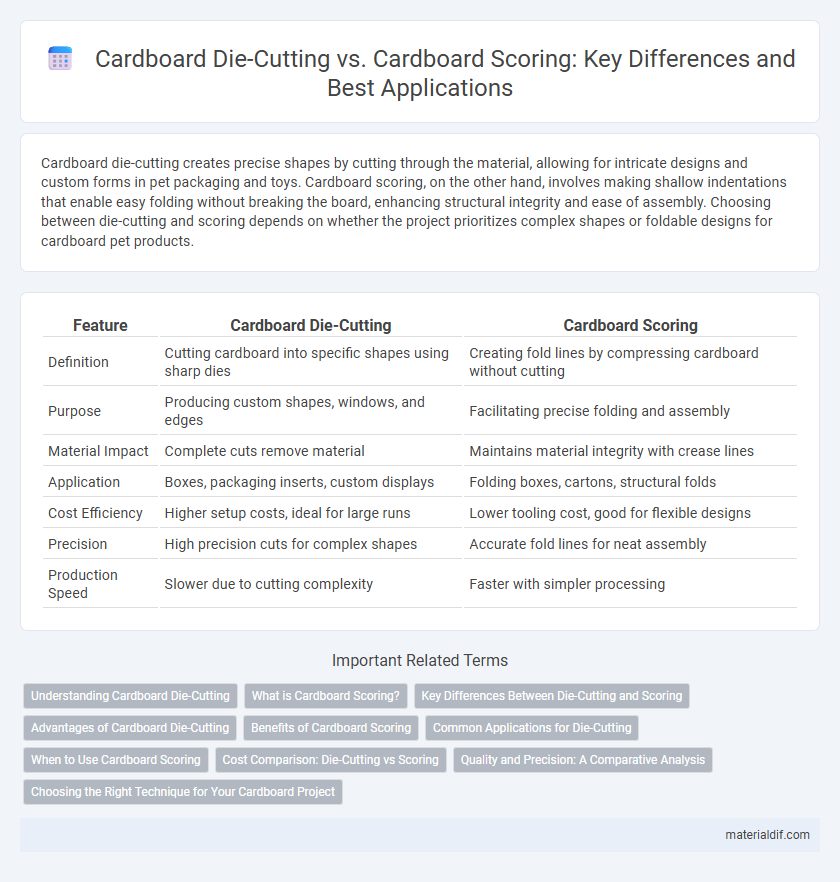

Cardboard die-cutting creates precise shapes by cutting through the material, allowing for intricate designs and custom forms in pet packaging and toys. Cardboard scoring, on the other hand, involves making shallow indentations that enable easy folding without breaking the board, enhancing structural integrity and ease of assembly. Choosing between die-cutting and scoring depends on whether the project prioritizes complex shapes or foldable designs for cardboard pet products.

Table of Comparison

| Feature | Cardboard Die-Cutting | Cardboard Scoring |

|---|---|---|

| Definition | Cutting cardboard into specific shapes using sharp dies | Creating fold lines by compressing cardboard without cutting |

| Purpose | Producing custom shapes, windows, and edges | Facilitating precise folding and assembly |

| Material Impact | Complete cuts remove material | Maintains material integrity with crease lines |

| Application | Boxes, packaging inserts, custom displays | Folding boxes, cartons, structural folds |

| Cost Efficiency | Higher setup costs, ideal for large runs | Lower tooling cost, good for flexible designs |

| Precision | High precision cuts for complex shapes | Accurate fold lines for neat assembly |

| Production Speed | Slower due to cutting complexity | Faster with simpler processing |

Understanding Cardboard Die-Cutting

Cardboard die-cutting involves using a custom-shaped blade to precisely cut out specific shapes from cardboard sheets, enabling the creation of complex designs, packaging, and display units with clean edges. Unlike scoring, which only creates fold lines without cutting through the material, die-cutting fully separates parts to form detailed contours and components essential for assembly. Mastery of die-cutting techniques optimizes production efficiency and enhances the structural integrity and aesthetic appeal of cardboard products.

What is Cardboard Scoring?

Cardboard scoring involves creating a shallow crease or groove on the cardboard surface to enable precise and clean folding without breaking the material fibers. This technique differs from die-cutting, which cuts out shapes entirely, as scoring maintains the structural integrity of the cardboard while allowing easy bending. Scoring is essential for producing custom packaging, boxes, and displays that require sharp, accurate folds for assembly and durability.

Key Differences Between Die-Cutting and Scoring

Die-cutting and scoring are essential processes in cardboard fabrication, with die-cutting involving cutting out shapes or designs using a precise steel blade, allowing for complex and intricate patterns. Scoring creates fold lines by compressing the cardboard without cutting through, enabling clean, crisp bends for folding and assembly. The key difference lies in die-cutting shaping the material while scoring prepares it for folding, both critical for efficient packaging production.

Advantages of Cardboard Die-Cutting

Cardboard die-cutting offers precise and intricate shapes that are difficult to achieve with scoring, enabling highly customizable packaging designs. This process enhances structural integrity and functionality by creating clean cuts and folds without compromising the material's strength. Die-cutting also improves production efficiency and consistency, reducing waste and allowing for rapid mass production of complex cardboard components.

Benefits of Cardboard Scoring

Cardboard scoring creates precise fold lines without damaging the material's structural integrity, allowing for clean, professional-looking bends ideal for packaging design. This technique enhances production efficiency by reducing waste and minimizing the risk of cracking compared to die-cutting. Scoring also facilitates easier assembly and improves the durability of folded cardboard products, making it a preferred method for manufacturers aiming for both quality and cost-effectiveness.

Common Applications for Die-Cutting

Cardboard die-cutting is widely used for creating intricate shapes and customized packaging designs, enabling precise cuts for product displays, promotional materials, and retail packaging. Common applications include custom boxes, inserts, and point-of-purchase displays where specific dimensions and unique graphics enhance branding and functionality. This process contrasts with cardboard scoring, which is primarily used to create fold lines for easy assembly rather than shaping the material.

When to Use Cardboard Scoring

Cardboard scoring is ideal for creating precise fold lines without cutting through the material, allowing for clean and accurate bends in packaging and display designs. It is commonly used when the structural integrity of the cardboard must be maintained, such as in folding cartons or product boxes that require sharp creases for assembly. Unlike die-cutting, which removes sections of cardboard, scoring focuses on enhancing flexibility and foldability to improve the final product's durability and appearance.

Cost Comparison: Die-Cutting vs Scoring

Cardboard die-cutting typically incurs higher upfront costs due to the need for custom dies and specialized machinery, making it more suitable for large production runs where per-unit costs decrease significantly. Scoring requires less equipment investment and is generally more cost-effective for smaller batches or simpler fold lines, since it involves creating creases without cutting through the material. Evaluating production volume and design complexity is essential to determine whether die-cutting or scoring provides the best cost efficiency for cardboard fabrication.

Quality and Precision: A Comparative Analysis

Cardboard die-cutting offers superior precision by enabling complex shapes and intricate designs with clean, sharp edges that enhance product quality. In contrast, cardboard scoring provides controlled folding lines, ensuring accurate bends without compromising the structural integrity of the material. Both methods significantly impact the final product's durability and appearance, with die-cutting excelling in detailed customization and scoring optimizing fold accuracy.

Choosing the Right Technique for Your Cardboard Project

Cardboard die-cutting creates precise, intricate shapes by cutting through the material, ideal for custom packaging and detailed designs. Cardboard scoring produces fold lines without cutting, enabling clean, accurate bends for boxes and displays. Selecting between die-cutting and scoring depends on project complexity, required structural integrity, and aesthetic design needs.

Cardboard die-cutting vs Cardboard scoring Infographic

materialdif.com

materialdif.com