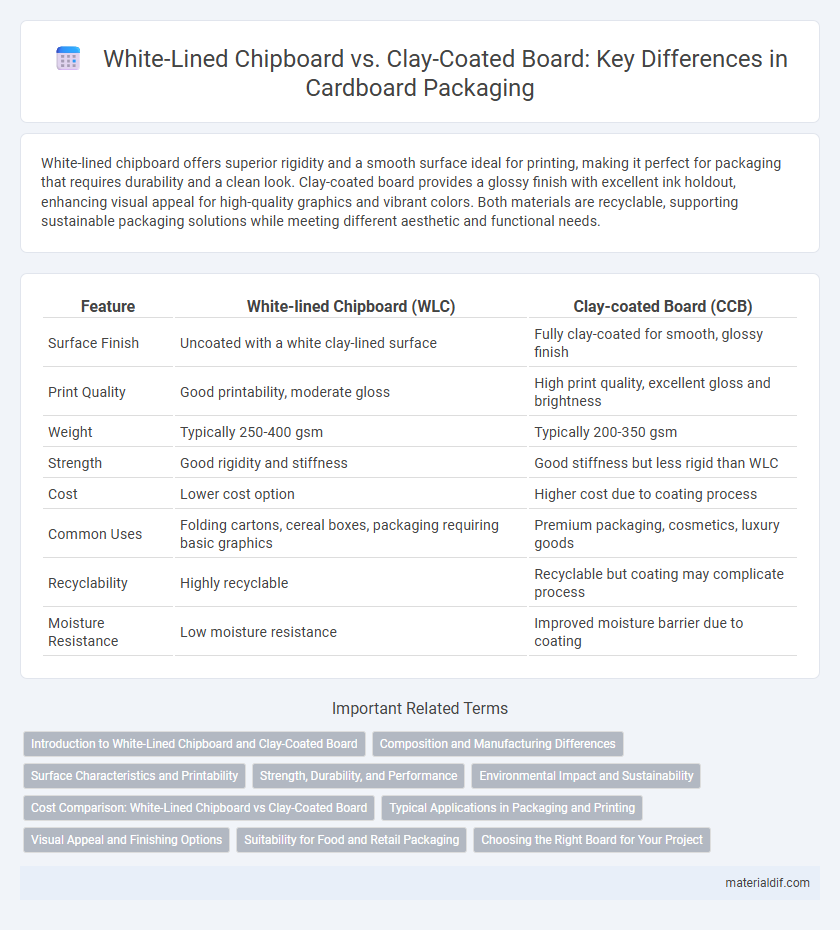

White-lined chipboard offers superior rigidity and a smooth surface ideal for printing, making it perfect for packaging that requires durability and a clean look. Clay-coated board provides a glossy finish with excellent ink holdout, enhancing visual appeal for high-quality graphics and vibrant colors. Both materials are recyclable, supporting sustainable packaging solutions while meeting different aesthetic and functional needs.

Table of Comparison

| Feature | White-lined Chipboard (WLC) | Clay-coated Board (CCB) |

|---|---|---|

| Surface Finish | Uncoated with a white clay-lined surface | Fully clay-coated for smooth, glossy finish |

| Print Quality | Good printability, moderate gloss | High print quality, excellent gloss and brightness |

| Weight | Typically 250-400 gsm | Typically 200-350 gsm |

| Strength | Good rigidity and stiffness | Good stiffness but less rigid than WLC |

| Cost | Lower cost option | Higher cost due to coating process |

| Common Uses | Folding cartons, cereal boxes, packaging requiring basic graphics | Premium packaging, cosmetics, luxury goods |

| Recyclability | Highly recyclable | Recyclable but coating may complicate process |

| Moisture Resistance | Low moisture resistance | Improved moisture barrier due to coating |

Introduction to White-Lined Chipboard and Clay-Coated Board

White-lined chipboard (WLC) is a recycled fiber board characterized by a white, printable surface liner and an uncoated, rough backside, commonly used in packaging applications due to its cost-effectiveness and sustainability. Clay-coated board, also known as solid bleached sulfate (SBS), features a smooth, glossy clay-coated surface on one or both sides, providing excellent printability and moisture resistance for high-end retail packaging. Both materials serve distinct purposes: WLC is preferred for eco-friendly, rigid packaging, while clay-coated board is chosen for premium visual appeal and durability.

Composition and Manufacturing Differences

White-lined chipboard consists primarily of recycled fibers and unbleached pulp, with multiple layers of white clay coating on the surface to enhance printability and smoothness. Clay-coated board features a solid bleached sulfate base paper coated with a smooth layer of kaolin clay, providing a high-gloss finish and superior print quality. Manufacturing of white-lined chipboard involves layering reclaimed materials and applying clay coating to the outer layers, while clay-coated board undergoes a more refined pulping and bleaching process before the clay is uniformly applied.

Surface Characteristics and Printability

White-lined chipboard features a smooth, uncoated surface with natural fibers visible, offering moderate printability suited for packaging where cost-effectiveness is prioritized. Clay-coated board boasts a glossy, highly smooth surface due to its fine clay layer, enabling superior printability with sharper image reproduction and vibrant colors. While white-lined chipboard absorbs ink more readily, clay-coated board provides enhanced ink holdout and sharper detail, making it ideal for high-quality graphic applications.

Strength, Durability, and Performance

White-lined chipboard offers superior strength and durability due to its multi-ply recycled fiber composition, making it ideal for structural packaging that requires robustness. Clay-coated board provides a smoother, high-gloss finish with excellent printability and moisture resistance, enhancing performance for retail packaging with visual appeal. While white-lined chipboard excels in heavy-duty applications, clay-coated board performs better in protecting contents against environmental factors and delivering premium surface quality.

Environmental Impact and Sustainability

White-lined chipboard (WLC) is often considered more sustainable due to its high recycled fiber content, reducing the demand for virgin materials and lowering landfill waste. Clay-coated board, while offering superior print quality and moisture resistance, commonly involves a higher environmental footprint because of the mineral clay coating and less recyclability. WLC's easier recyclability and lower energy consumption in production make it a preferred choice for eco-conscious packaging solutions.

Cost Comparison: White-Lined Chipboard vs Clay-Coated Board

White-lined chipboard typically costs less than clay-coated board due to its simpler manufacturing process and lower material expenses. Clay-coated board involves additional coating steps and higher-quality raw materials, increasing production costs significantly. For businesses prioritizing budget-friendly packaging with moderate print quality, white-lined chipboard offers a more economical option compared to the higher-priced, premium finish of clay-coated board.

Typical Applications in Packaging and Printing

White-lined chipboard is commonly used in packaging applications such as cereal boxes, shoe boxes, and retail product packaging due to its cost-effectiveness and printability. Clay-coated board is preferred for high-end packaging and printing needs, providing a smooth, glossy finish ideal for luxury goods, cosmetics, and food packaging that requires vibrant graphics and detailed images. Both types offer distinct advantages, with white-lined chipboard excelling in durability and recyclability, while clay-coated board enhances visual appeal and product presentation.

Visual Appeal and Finishing Options

White-lined chipboard offers a smooth, matte surface ideal for natural, understated packaging designs, providing excellent printability for bold graphics and texts. Clay-coated board features a glossy, bright white surface that enhances color vibrancy and sharpness, making it perfect for high-end packaging requiring premium visual appeal. Both options support various finishing techniques such as embossing, debossing, and spot UV, with clay-coated board often preferred for intricate finishes due to its superior print surface.

Suitability for Food and Retail Packaging

White-lined chipboard offers excellent structural strength and cost-effectiveness, making it a popular choice for retail packaging where durability is essential. Clay-coated board features a smooth, glossy surface with superior print quality and moisture resistance, ideal for food packaging requiring hygiene and aesthetic appeal. Both materials comply with food safety regulations, but clay-coated board is preferred when high-quality graphics and barrier properties are crucial for product protection.

Choosing the Right Board for Your Project

White-lined chipboard offers excellent rigidity and is ideal for packaging that requires durability and cost-effectiveness, while clay-coated board provides a smooth, printable surface perfect for high-quality graphics and luxury packaging. Selecting the right board depends on the specific needs of your project, such as the desired finish, printing quality, and structural strength. For projects demanding vibrant visuals and premium appeal, clay-coated board is preferable, whereas white-lined chipboard suits more functional, budget-conscious applications.

White-lined chipboard vs Clay-coated board Infographic

materialdif.com

materialdif.com