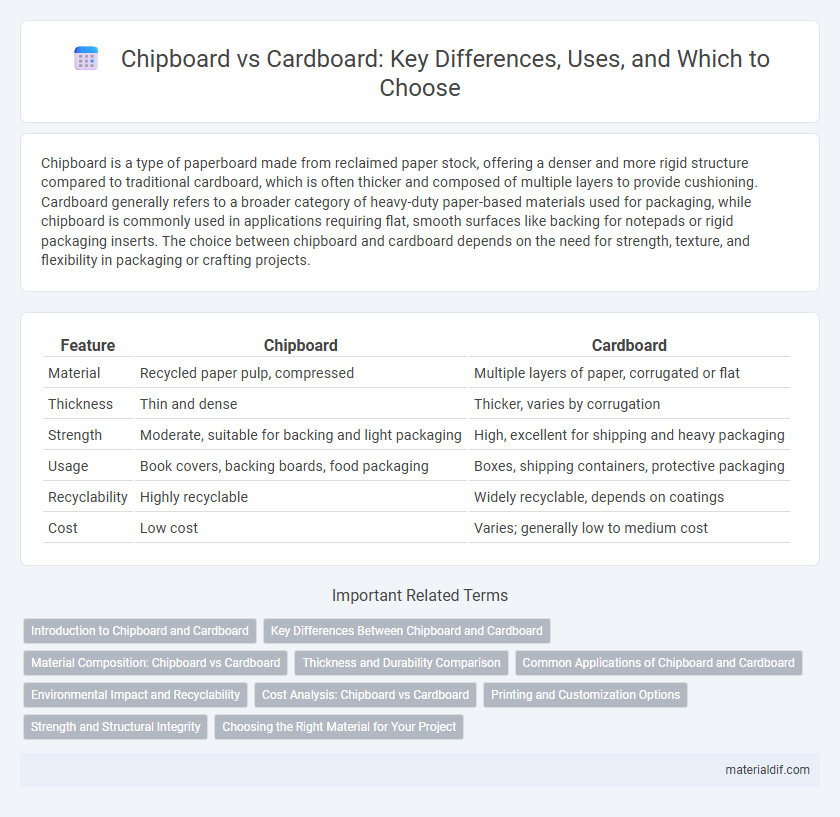

Chipboard is a type of paperboard made from reclaimed paper stock, offering a denser and more rigid structure compared to traditional cardboard, which is often thicker and composed of multiple layers to provide cushioning. Cardboard generally refers to a broader category of heavy-duty paper-based materials used for packaging, while chipboard is commonly used in applications requiring flat, smooth surfaces like backing for notepads or rigid packaging inserts. The choice between chipboard and cardboard depends on the need for strength, texture, and flexibility in packaging or crafting projects.

Table of Comparison

| Feature | Chipboard | Cardboard |

|---|---|---|

| Material | Recycled paper pulp, compressed | Multiple layers of paper, corrugated or flat |

| Thickness | Thin and dense | Thicker, varies by corrugation |

| Strength | Moderate, suitable for backing and light packaging | High, excellent for shipping and heavy packaging |

| Usage | Book covers, backing boards, food packaging | Boxes, shipping containers, protective packaging |

| Recyclability | Highly recyclable | Widely recyclable, depends on coatings |

| Cost | Low cost | Varies; generally low to medium cost |

Introduction to Chipboard and Cardboard

Chipboard and cardboard are both paper-based materials widely used for packaging and crafting, but they differ significantly in composition and strength. Chipboard is made from recycled paper and wood pulp, offering a dense, sturdy surface ideal for backing, book covers, and furniture applications. Cardboard generally refers to a thicker paperboard used for shipping boxes and retail packaging, providing lightweight yet durable protection.

Key Differences Between Chipboard and Cardboard

Chipboard is a type of cardboard made from reclaimed paper stock, resulting in a denser and more rigid material often used for backing, book covers, and packaging. Cardboard is a broader category that includes various paper-based materials, including chipboard and corrugated fiberboard, typically lighter and less durable than chipboard. Key differences include thickness, strength, and manufacturing process, with chipboard being more uniform and sturdy compared to the more versatile and lightweight cardboard options.

Material Composition: Chipboard vs Cardboard

Chipboard consists primarily of reclaimed paper pulp compressed into thick, rigid sheets, offering strength and durability for various packaging applications. Cardboard, often referring to corrugated fiberboard, includes multiple layers with a fluted inner core sandwiched between linerboards, enhancing its structural integrity and cushioning properties. The distinct material composition of chipboard and cardboard determines their suitability for different uses, with chipboard favored for lighter, solid packaging and cardboard ideal for protective shipping containers.

Thickness and Durability Comparison

Chipboard typically ranges from 0.5mm to 2mm in thickness, making it thinner and less rigid than most cardboard, which generally starts around 1.5mm and can exceed 4mm for heavy-duty applications. Durability comparisons show that cardboard, especially corrugated types, offers superior strength and impact resistance due to its fluted inner layer, while chipboard's compressed fiber composition provides moderate stiffness but lower durability under stress. Selecting between chipboard and cardboard depends on the need for sturdiness and thickness, with cardboard favored for robust packaging and chipboard suited for lightweight, low-impact uses.

Common Applications of Chipboard and Cardboard

Chipboard is commonly used for packaging, bookbinding, and as backing material due to its rigidity and smooth surface. Cardboard, known for its corrugated layers, is primarily employed in shipping boxes, product packaging, and storage containers because of its strength and cushioning properties. Both materials serve distinct purposes in packaging and crafting industries, with chipboard favored for durability and cardboard for protective shipping solutions.

Environmental Impact and Recyclability

Chipboard, often made from recycled paper fiber, typically has a lower environmental impact compared to conventional cardboard due to its efficient reuse of post-consumer materials. Both chipboard and cardboard are widely recyclable, but chipboard's thinner composition allows for easier processing and quicker breakdown in recycling facilities. Choosing chipboard supports sustainable packaging solutions by reducing waste and conserving natural resources more effectively than standard cardboard.

Cost Analysis: Chipboard vs Cardboard

Chipboard typically costs less than cardboard due to its lower density and simpler manufacturing process, making it a budget-friendly option for packaging and crafting. Cardboard, especially corrugated varieties, involves higher production costs because of its layered structure, which provides enhanced durability and protection. Businesses often weigh the cost benefits of chipboard against the superior strength and versatility of cardboard when selecting materials for specific applications.

Printing and Customization Options

Chipboard offers a smooth surface ideal for high-quality printing with detailed graphics and vibrant colors, making it suitable for premium packaging or custom projects requiring sharp image reproduction. Cardboard, especially corrugated types, provides durability but presents challenges for fine printing due to its textured surface, limiting customization to simpler designs or the use of additional printing layers. Customization options for chipboard often include embossing, debossing, and foil stamping, while cardboard primarily supports basic printing methods and exterior coatings to enhance visual appeal.

Strength and Structural Integrity

Chipboard offers higher strength and structural integrity compared to typical cardboard due to its denser, compressed wood fibers. It provides improved rigidity and resistance to bending, making it ideal for applications requiring durable support and load-bearing capacity. Cardboard, often lighter and less dense, suits packaging needs where flexibility and cushioning outweigh structural demands.

Choosing the Right Material for Your Project

Chipboard, composed of recycled paper fibers pressed into a dense sheet, offers greater rigidity and smooth surfaces ideal for packaging and model making. Cardboard, typically corrugated with fluted layers between liners, provides superior strength and cushioning, making it best suited for shipping and heavy-duty applications. Selecting the right material depends on project requirements such as durability, weight, and finish, where chipboard excels in precision and aesthetics while cardboard dominates in protection and structural support.

Chipboard vs Cardboard Infographic

materialdif.com

materialdif.com