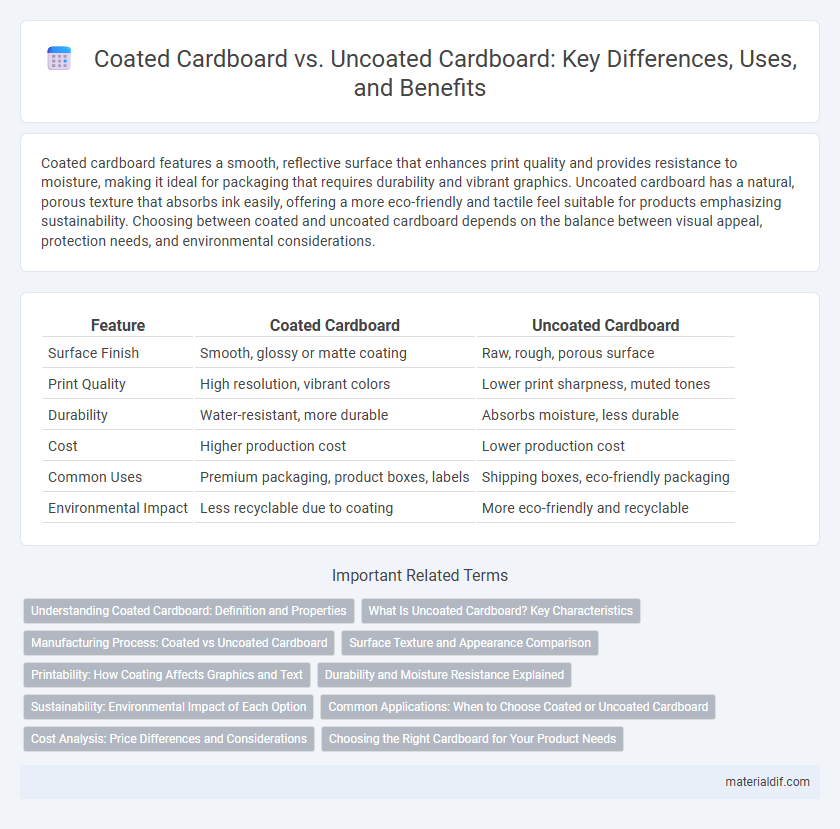

Coated cardboard features a smooth, reflective surface that enhances print quality and provides resistance to moisture, making it ideal for packaging that requires durability and vibrant graphics. Uncoated cardboard has a natural, porous texture that absorbs ink easily, offering a more eco-friendly and tactile feel suitable for products emphasizing sustainability. Choosing between coated and uncoated cardboard depends on the balance between visual appeal, protection needs, and environmental considerations.

Table of Comparison

| Feature | Coated Cardboard | Uncoated Cardboard |

|---|---|---|

| Surface Finish | Smooth, glossy or matte coating | Raw, rough, porous surface |

| Print Quality | High resolution, vibrant colors | Lower print sharpness, muted tones |

| Durability | Water-resistant, more durable | Absorbs moisture, less durable |

| Cost | Higher production cost | Lower production cost |

| Common Uses | Premium packaging, product boxes, labels | Shipping boxes, eco-friendly packaging |

| Environmental Impact | Less recyclable due to coating | More eco-friendly and recyclable |

Understanding Coated Cardboard: Definition and Properties

Coated cardboard features a surface layer of clay, latex, or other substances applied to enhance printability, water resistance, and durability, making it ideal for packaging and high-quality printing applications. This coating improves stiffness and provides a smooth finish, allowing sharper graphics and vibrant colors compared to uncoated cardboard. Understanding its properties helps manufacturers select the appropriate material for specific needs such as food packaging, retail displays, or luxury product boxes.

What Is Uncoated Cardboard? Key Characteristics

Uncoated cardboard is a type of paperboard without a glossy or coated surface, characterized by its natural, porous texture that allows for excellent ink absorption and ease of recycling. It is commonly used for packaging, cartons, and craft projects due to its durability, flexibility, and eco-friendly properties. This cardboard typically offers a matte finish, making it ideal for printing techniques that require high ink holdout and a more tactile, organic feel.

Manufacturing Process: Coated vs Uncoated Cardboard

Coated cardboard undergoes an additional finishing step where a layer of clay, latex, or polymer is applied to its surface, enhancing smoothness, printability, and moisture resistance. Uncoated cardboard skips this step, resulting in a rougher texture with higher porosity, which affects ink absorption and durability. The coating process involves specialized machinery and drying systems, increasing production complexity and cost compared to the simpler manufacturing of uncoated cardboard.

Surface Texture and Appearance Comparison

Coated cardboard features a smooth, glossy surface achieved through a layer of clay or polymer, enhancing its brightness and print clarity, making it ideal for high-quality packaging and graphic designs. Uncoated cardboard has a rougher, matte texture that absorbs ink more readily, resulting in a natural, tactile finish favored for eco-friendly or rustic packaging. The distinct surface textures directly influence visual appeal and functional applications, with coated cardboard offering vibrant colors and sharper images, while uncoated provides a subdued, organic look.

Printability: How Coating Affects Graphics and Text

Coated cardboard features a smooth, sealed surface that significantly enhances printability by allowing sharper, more vibrant graphics and crisp text, making it ideal for high-quality packaging and promotional materials. Uncoated cardboard has a porous texture that absorbs ink, resulting in softer, more muted colors and less precise detail, which suits more rustic or eco-friendly branding. The coating acts as a barrier, preventing ink bleed and enabling finer detail reproduction, crucial for intricate designs and professional-grade prints.

Durability and Moisture Resistance Explained

Coated cardboard features a smooth, sealed surface that significantly enhances its durability and moisture resistance, making it ideal for packaging products exposed to moisture or rough handling. Uncoated cardboard, while more eco-friendly and easier to recycle, lacks this protective layer, resulting in lower resistance to water and physical wear. The choice between coated and uncoated cardboard depends on the specific requirements for protection, longevity, and environmental impact in packaging applications.

Sustainability: Environmental Impact of Each Option

Coated cardboard often involves plastic or chemical layers that hinder biodegradability and recycling processes, contributing to greater environmental impact compared to uncoated cardboard. Uncoated cardboard is more eco-friendly, as it is fully recyclable, compostable, and decomposes faster, reducing landfill waste and pollution. Choosing uncoated cardboard supports sustainable practices by minimizing resource consumption and promoting circular economy principles.

Common Applications: When to Choose Coated or Uncoated Cardboard

Coated cardboard is ideal for packaging that requires a smooth finish, vibrant printing, and moisture resistance, making it common in product boxes, food packaging, and retail displays. Uncoated cardboard is preferred for applications where recyclability, breathability, and a natural look are important, such as shipping boxes, eco-friendly packaging, and craft projects. Choosing coated or uncoated cardboard depends on whether visual appeal and protection or sustainability and cost-effectiveness are the priority.

Cost Analysis: Price Differences and Considerations

Coated cardboard typically costs 15-25% more than uncoated cardboard due to the additional surface treatment that enhances durability and print quality. Businesses must weigh the cost premium against benefits such as improved moisture resistance and visual appeal when selecting packaging materials. Volume purchasing and supplier negotiations can significantly influence the final price difference between coated and uncoated cardboard options.

Choosing the Right Cardboard for Your Product Needs

Coated cardboard offers a smooth, glossy finish that enhances print quality and provides moisture resistance, making it ideal for packaging products requiring durability and visual appeal. Uncoated cardboard, with its natural texture and breathability, is a cost-effective and eco-friendly option suitable for products needing ventilation or a rustic look. Assess product protection requirements, aesthetic preferences, and environmental impact to choose the right cardboard type for packaging success.

Coated Cardboard vs Uncoated Cardboard Infographic

materialdif.com

materialdif.com