Kraft linerboard is made from virgin wood fibers, offering superior strength, durability, and moisture resistance compared to test linerboard, which is primarily produced from recycled fibers. Kraft linerboard is ideal for heavy-duty packaging and high-quality printing applications, whereas test linerboard is more cost-effective and suitable for general-purpose packaging where durability is less critical. Choosing between kraft and test linerboard depends on the specific performance requirements and environmental considerations of the cardboard product.

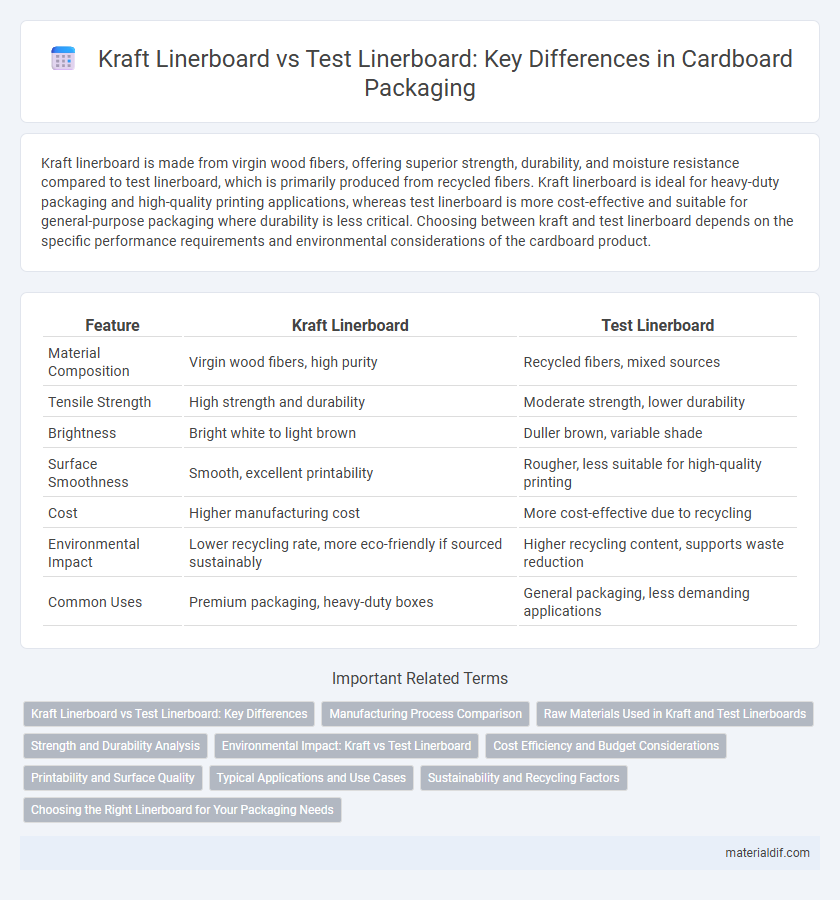

Table of Comparison

| Feature | Kraft Linerboard | Test Linerboard |

|---|---|---|

| Material Composition | Virgin wood fibers, high purity | Recycled fibers, mixed sources |

| Tensile Strength | High strength and durability | Moderate strength, lower durability |

| Brightness | Bright white to light brown | Duller brown, variable shade |

| Surface Smoothness | Smooth, excellent printability | Rougher, less suitable for high-quality printing |

| Cost | Higher manufacturing cost | More cost-effective due to recycling |

| Environmental Impact | Lower recycling rate, more eco-friendly if sourced sustainably | Higher recycling content, supports waste reduction |

| Common Uses | Premium packaging, heavy-duty boxes | General packaging, less demanding applications |

Kraft Linerboard vs Test Linerboard: Key Differences

Kraft linerboard is produced from virgin wood fibers using the kraft process, offering superior strength, durability, and resistance to moisture compared to test linerboard, which is primarily made from recycled fibers. The higher tear resistance and stiffness of kraft linerboard make it ideal for packaging heavy or high-value products, while test linerboard is commonly used for less demanding applications due to its cost-effectiveness. Environmental impact also differs; kraft linerboard generally requires more energy and resources but delivers enhanced performance and longevity.

Manufacturing Process Comparison

Kraft linerboard is produced using virgin wood fibers through the kraft pulping process, which involves chemical treatment to remove lignin and impurities, resulting in stronger and more durable boards. Test linerboard primarily uses recycled fibers and is manufactured via mechanical pulping, which preserves fiber length but may include residual contaminants, affecting strength. The kraft process demands higher energy and chemical inputs but yields superior quality suitable for heavy-duty packaging, while test linerboard offers an eco-friendlier option with moderate strength for lighter applications.

Raw Materials Used in Kraft and Test Linerboards

Kraft linerboard is produced primarily from virgin wood fibers through the kraft pulping process, which ensures high strength and durability due to the long fiber content. Test linerboard, on the other hand, predominantly uses recycled fibers or secondary fiber sources, resulting in a more eco-friendly option but with comparatively lower strength. The raw material choice directly impacts the board's performance, cost, and recyclability in packaging applications.

Strength and Durability Analysis

Kraft linerboard boasts superior strength and durability due to its unbleached pulp fibers, which provide enhanced tear resistance and rigidity essential for heavy-duty cardboard applications. Test linerboard, composed of recycled fibers, offers adequate strength for moderate packaging needs but generally exhibits lower durability and higher susceptibility to moisture damage compared to Kraft liner. The fiber composition and manufacturing process distinctly influence the mechanical properties, making Kraft linerboard preferable for long-term, high-stress packaging scenarios.

Environmental Impact: Kraft vs Test Linerboard

Kraft linerboard, produced from virgin wood fibers using a chemical pulping process, generally has a higher environmental impact due to energy-intensive methods and less reliance on recycled materials. Test linerboard, primarily made from recycled fibers, offers a lower carbon footprint by reducing waste and conserving natural resources. Choosing test linerboard supports sustainable packaging initiatives by minimizing deforestation and promoting circular economy practices.

Cost Efficiency and Budget Considerations

Kraft linerboard offers superior strength and durability, making it cost-efficient for heavy-duty packaging despite a higher initial price compared to test linerboard. Test linerboard, made from recycled fibers, is more budget-friendly but may require additional layers or reinforcement, potentially increasing overall costs in demanding applications. Choosing between kraft and test linerboard depends on balancing upfront expenses with long-term performance requirements and packaging durability.

Printability and Surface Quality

Kraft linerboard offers superior printability and surface quality due to its long fiber content and minimal impurities, resulting in a smoother and more consistent surface ideal for high-quality graphic applications. Test linerboard, made primarily from recycled fibers, typically has a rougher surface and lower brightness, which can compromise print clarity and color vibrancy. Selecting kraft linerboard enhances the visual appeal and durability of packaging by providing a clean, uniform surface that supports sharp, detailed printing.

Typical Applications and Use Cases

Kraft linerboard is predominantly used in packaging applications requiring high strength and durability, such as corrugated boxes for heavy-duty shipping and protective packaging. Test linerboard often serves in applications involving recycled content and cost-effective packaging solutions like inner corrugating facers and consumer goods cartons. Both materials are essential in the cardboard industry, with kraft linerboard favored for premium, load-bearing applications and test linerboard chosen for sustainability and economic efficiency.

Sustainability and Recycling Factors

Kraft linerboard is produced using virgin fibers from sustainable softwood sources, offering superior strength and enhanced recyclability due to its high fiber quality, which supports multiple recycling cycles without significant degradation. Test linerboard, often made from recycled fiber and printed waste paper, contributes to circular economy efforts but may have lower durability and a shorter recycling lifespan because of fiber shortening and contamination risks. The choice between kraft and test linerboard significantly impacts overall sustainability profiles, with kraft linerboard favoring long-term recyclability and test linerboard promoting immediate reuse of post-consumer waste materials.

Choosing the Right Linerboard for Your Packaging Needs

Kraft linerboard offers superior strength and moisture resistance, making it ideal for heavy-duty packaging and shipping applications. Test linerboard, produced from recycled fibers, provides a more cost-effective and environmentally friendly option suitable for lighter packaging needs. Selecting the right linerboard depends on balancing durability requirements with budget constraints and sustainability goals.

Kraft linerboard vs Test linerboard Infographic

materialdif.com

materialdif.com