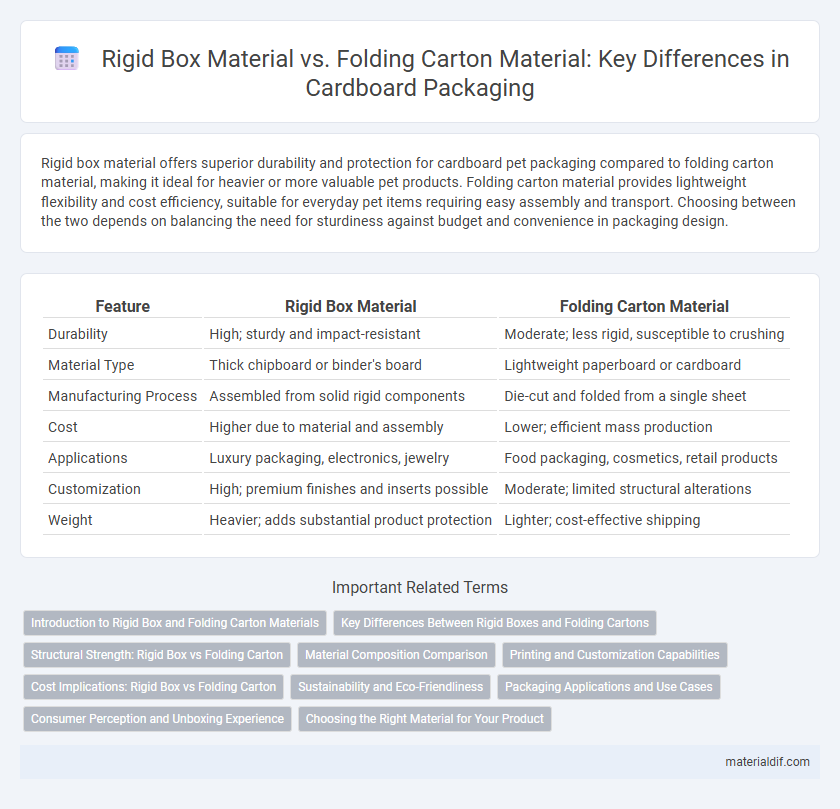

Rigid box material offers superior durability and protection for cardboard pet packaging compared to folding carton material, making it ideal for heavier or more valuable pet products. Folding carton material provides lightweight flexibility and cost efficiency, suitable for everyday pet items requiring easy assembly and transport. Choosing between the two depends on balancing the need for sturdiness against budget and convenience in packaging design.

Table of Comparison

| Feature | Rigid Box Material | Folding Carton Material |

|---|---|---|

| Durability | High; sturdy and impact-resistant | Moderate; less rigid, susceptible to crushing |

| Material Type | Thick chipboard or binder's board | Lightweight paperboard or cardboard |

| Manufacturing Process | Assembled from solid rigid components | Die-cut and folded from a single sheet |

| Cost | Higher due to material and assembly | Lower; efficient mass production |

| Applications | Luxury packaging, electronics, jewelry | Food packaging, cosmetics, retail products |

| Customization | High; premium finishes and inserts possible | Moderate; limited structural alterations |

| Weight | Heavier; adds substantial product protection | Lighter; cost-effective shipping |

Introduction to Rigid Box and Folding Carton Materials

Rigid box materials consist of thick, sturdy paperboard or chipboard that provides durability and premium protection, often used for luxury packaging and high-end products. Folding carton materials are made from thinner, lighter paperboard designed for easy folding and assembly, commonly utilized for retail packaging and mass-produced consumer goods. Both materials offer versatile printing options and eco-friendly choices, but rigid boxes emphasize robustness while folding cartons prioritize cost-effectiveness and convenience.

Key Differences Between Rigid Boxes and Folding Cartons

Rigid box material is typically thicker, made from high-density paperboard or chipboard, providing enhanced durability and a premium feel, while folding carton material uses lightweight, flexible paperboard designed for easy folding and cost-effectiveness. Rigid boxes offer structural integrity with a solid, non-collapsible form ideal for luxury packaging, whereas folding cartons are designed for quick assembly, efficient storage, and mass production. The key differences lie in material thickness, rigidity, manufacturing complexity, and application suitability, with rigid boxes favored for high-end products and folding cartons for everyday consumer goods.

Structural Strength: Rigid Box vs Folding Carton

Rigid box material offers superior structural strength compared to folding carton material due to its thicker paperboard layers and multi-ply construction, which resist crushing and provide enhanced durability. Folding carton material typically consists of thinner, single- or double-ply paperboard that is more vulnerable to bending and compression under weight or pressure. This makes rigid boxes ideal for premium packaging requiring protection against impact and deformation, while folding cartons suit lightweight, less fragile products.

Material Composition Comparison

Rigid box material typically consists of thick, multi-ply paperboard layers glued together, providing enhanced strength and durability compared to folding carton material. Folding cartons use a single layer of paperboard, often coated or laminated for surface finish and light protection, making them lightweight but less structurally robust. The denser composition of rigid box material allows for superior resistance to crushing and better protection for high-end products.

Printing and Customization Capabilities

Rigid box material offers superior printing quality and customization options due to its thicker, more durable surface, allowing for high-resolution graphics and embossing techniques. Folding carton material, while more flexible and cost-effective, supports vibrant printing but may limit advanced customization such as foil stamping or deep embossing. Brands seeking premium visual impact often prefer rigid boxes, whereas folding cartons suit mass production with efficient, scalable printing processes.

Cost Implications: Rigid Box vs Folding Carton

Rigid box materials typically involve higher production costs due to thicker substrates and complex assembly processes, resulting in significant upfront investment. Folding carton materials use thinner paperboards that reduce material expenses and allow for efficient mass production with lower labor costs. This cost efficiency makes folding cartons more suitable for budget-conscious packaging solutions, while rigid boxes cater to premium products requiring durability and aesthetic appeal.

Sustainability and Eco-Friendliness

Rigid box material typically consists of thicker, denser paperboard, offering enhanced durability but often requiring more resources to produce, which can impact sustainability. Folding carton material is lighter and uses less raw material, making it more eco-friendly through reduced waste and easier recyclability. Both materials can be sourced from recycled fibers, but folding cartons generally have a lower carbon footprint due to their efficient manufacturing and transportation.

Packaging Applications and Use Cases

Rigid box material offers superior strength and durability, making it ideal for premium packaging applications such as luxury goods, electronics, and high-end cosmetics. Folding carton material provides lightweight and cost-effective solutions commonly used for food products, pharmaceuticals, and retail packaging where easy storage and transportation are essential. The choice between rigid and folding cartons depends on product protection requirements, brand positioning, and logistics considerations.

Consumer Perception and Unboxing Experience

Rigid box material offers superior durability and a premium feel that enhances consumer perception by conveying luxury and sturdiness, often associated with high-end products. Folding carton material, while cost-effective and lightweight, provides flexibility in design but may be perceived as less prestigious, impacting the unboxing experience by feeling less substantial. The tactile quality and structural integrity of rigid boxes contribute to a more memorable and satisfying unboxing experience, influencing repeat purchases and brand loyalty.

Choosing the Right Material for Your Product

Rigid boxes, made from thick, sturdy paperboard, provide superior protection and an upscale appearance ideal for luxury products and heavy items. Folding cartons use lighter, flexible paperboard that is cost-effective and suitable for lightweight goods requiring easy storage and shipping. Selecting the right material depends on product weight, protection needs, branding goals, and budget constraints to ensure optimal functionality and customer appeal.

Rigid box material vs Folding carton material Infographic

materialdif.com

materialdif.com