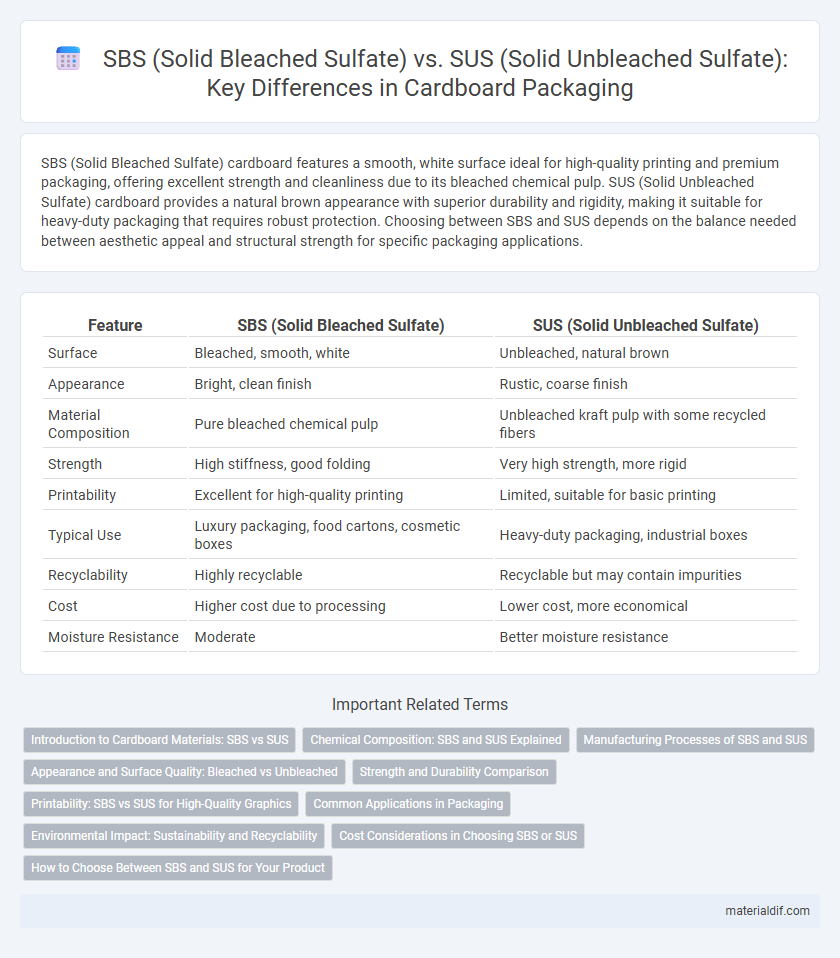

SBS (Solid Bleached Sulfate) cardboard features a smooth, white surface ideal for high-quality printing and premium packaging, offering excellent strength and cleanliness due to its bleached chemical pulp. SUS (Solid Unbleached Sulfate) cardboard provides a natural brown appearance with superior durability and rigidity, making it suitable for heavy-duty packaging that requires robust protection. Choosing between SBS and SUS depends on the balance needed between aesthetic appeal and structural strength for specific packaging applications.

Table of Comparison

| Feature | SBS (Solid Bleached Sulfate) | SUS (Solid Unbleached Sulfate) |

|---|---|---|

| Surface | Bleached, smooth, white | Unbleached, natural brown |

| Appearance | Bright, clean finish | Rustic, coarse finish |

| Material Composition | Pure bleached chemical pulp | Unbleached kraft pulp with some recycled fibers |

| Strength | High stiffness, good folding | Very high strength, more rigid |

| Printability | Excellent for high-quality printing | Limited, suitable for basic printing |

| Typical Use | Luxury packaging, food cartons, cosmetic boxes | Heavy-duty packaging, industrial boxes |

| Recyclability | Highly recyclable | Recyclable but may contain impurities |

| Cost | Higher cost due to processing | Lower cost, more economical |

| Moisture Resistance | Moderate | Better moisture resistance |

Introduction to Cardboard Materials: SBS vs SUS

SBS (Solid Bleached Sulfate) cardboard is a premium paperboard made from bleached chemical pulp, offering a smooth, white surface ideal for high-quality printing and packaging. SUS (Solid Unbleached Sulfate) cardboard is produced from unbleached chemical pulp, resulting in a stronger, brownish material commonly used for heavy-duty packaging and structural applications. Both materials provide excellent stiffness and durability, with SBS favored for aesthetic appeal and SUS chosen for strength and cost-effectiveness in cardboard manufacturing.

Chemical Composition: SBS and SUS Explained

Solid Bleached Sulfate (SBS) is made from bleached virgin wood fibers, resulting in a chemically pure cellulose structure with minimal lignin and hemicellulose, which enhances its brightness and cleanliness for high-quality printing and packaging. Solid Unbleached Sulfate (SUS) contains unbleached virgin fibers, retaining higher lignin content that gives it increased strength and durability but a darker appearance compared to SBS. The chemical composition difference between SBS and SUS directly influences their physical properties, making SBS ideal for visual presentation and SUS preferred for structural applications in cardboard manufacturing.

Manufacturing Processes of SBS and SUS

SBS (Solid Bleached Sulfate) is manufactured using bleached virgin wood fibers through a chemical pulping process that removes lignin, resulting in a bright white, smooth surface ideal for high-quality printing and packaging. SUS (Solid Unbleached Sulfate) undergoes a similar kraft pulping process but retains the natural brown color of unbleached fibers, offering greater strength and rigidity suited for heavy-duty packaging. The manufacturing difference lies in the bleaching stage, where SBS incorporates a bleaching process for purity and aesthetic appeal, while SUS emphasizes durability by preserving the fiber's natural state.

Appearance and Surface Quality: Bleached vs Unbleached

SBS (Solid Bleached Sulfate) cardboard offers a bright white and smooth surface, making it ideal for high-quality printing and premium packaging with superior visual appeal. In contrast, SUS (Solid Unbleached Sulfate) features a natural brown, unbleached appearance with a coarser texture, providing excellent strength but less visual refinement. The choice between bleached SBS and unbleached SUS depends on the priority of aesthetic presentation versus durability and rustic appeal.

Strength and Durability Comparison

SBS (Solid Bleached Sulfate) cardboard offers superior surface smoothness and brightness, making it ideal for high-quality printing, while SUS (Solid Unbleached Sulfate) excels in strength and durability due to its unbleached fibers, providing better resistance to moisture and impact. The unbleached fibers in SUS contribute to greater tear resistance and load-bearing capacity, making it more suitable for heavy-duty packaging that requires enhanced protection. SBS, although less durable than SUS, remains preferred for premium packaging where aesthetic appeal and print clarity are critical.

Printability: SBS vs SUS for High-Quality Graphics

SBS (Solid Bleached Sulfate) cardboard offers superior printability for high-quality graphics due to its smooth, white, and uniform surface that enhances color vibrancy and detail accuracy. SUS (Solid Unbleached Sulfate) features a natural, brown kraft appearance with a rougher texture, which can absorb more ink and reduce print sharpness and color contrast. For premium packaging and marketing materials requiring vivid graphic reproduction, SBS is the preferred choice over SUS.

Common Applications in Packaging

SBS (Solid Bleached Sulfate) cardboard is widely used in high-end packaging for cosmetics, pharmaceuticals, and food products due to its bright white surface, excellent printability, and food-safe properties. SUS (Solid Unbleached Sulfate) cardboard is preferred for heavy-duty packaging applications such as beverage carriers, beverage bottle packaging, and industrial product cartons because of its natural brown color, superior strength, and durability. Both materials serve distinct packaging needs, with SBS chosen for visual appeal and hygiene, while SUS prioritizes robustness and cost-efficiency.

Environmental Impact: Sustainability and Recyclability

SBS (Solid Bleached Sulfate) cardboard is made from virgin wood fibers with a bleached, white surface, offering high recyclability but involving higher chemical processing that can impact environmental sustainability. SUS (Solid Unbleached Sulfate) cardboard uses unbleached fibers, reducing chemical usage and energy consumption, which enhances its eco-friendly profile and supports sustainable forestry practices. Both materials are recyclable, but SUS generally has a lower environmental footprint due to fewer processing steps and better biodegradability.

Cost Considerations in Choosing SBS or SUS

SBS (Solid Bleached Sulfate) typically incurs higher production costs compared to SUS (Solid Unbleached Sulfate) due to its bleaching process and superior purity, making it ideal for premium packaging requiring superior printability and aesthetics. SUS offers a cost-effective alternative with greater mechanical strength and durability, often chosen for industrial and heavy-duty packaging applications where visual appeal is less critical. Evaluating total cost of ownership must consider both material expenses and end-use requirements, balancing budget constraints with functional performance.

How to Choose Between SBS and SUS for Your Product

Choosing between SBS (Solid Bleached Sulfate) and SUS (Solid Unbleached Sulfate) depends on product presentation and strength requirements. SBS offers a premium white surface ideal for high-quality graphics and retail packaging, providing excellent printability and a clean appearance. SUS, with its natural brown color and superior durability, is best suited for heavy-duty packaging and protective applications where strength is prioritized over aesthetics.

SBS (Solid Bleached Sulfate) vs SUS (Solid Unbleached Sulfate) Infographic

materialdif.com

materialdif.com