Cardboard die-cutting creates precise, clean shapes by cutting through the material entirely, making it ideal for assembling sturdy, intricate pet structures with exact edges. Cardboard perforation involves making a series of small holes or slits without cutting through fully, allowing easy folding or tear-off sections, which is useful for adjustable or interactive parts of pet designs. Choosing between die-cutting and perforation depends on the desired durability and functionality of the cardboard pet model.

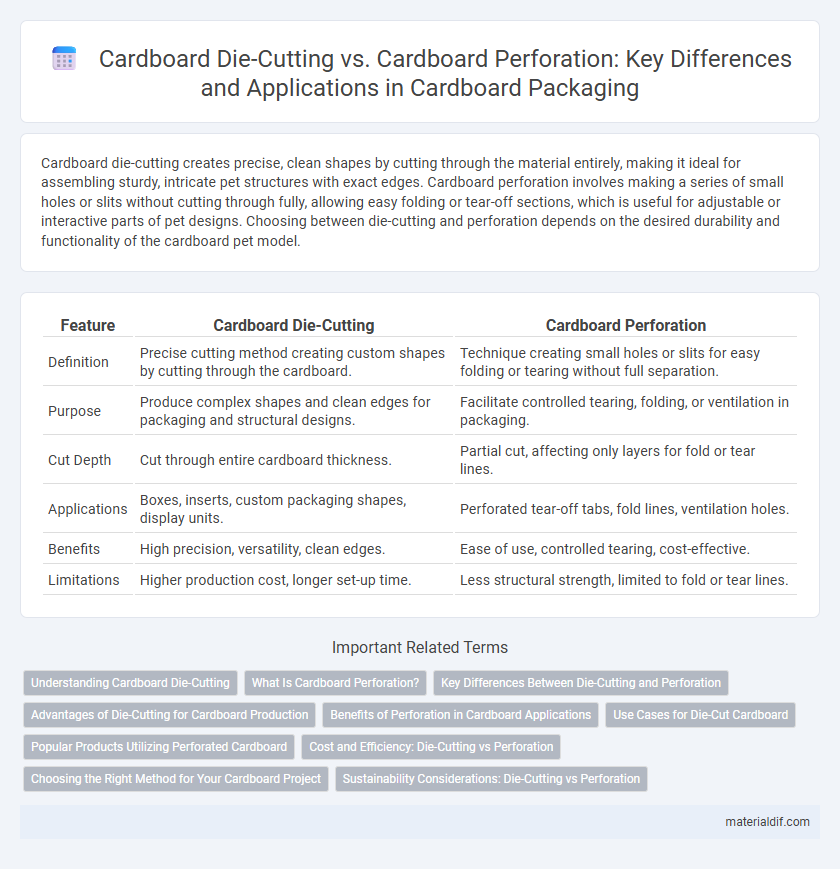

Table of Comparison

| Feature | Cardboard Die-Cutting | Cardboard Perforation |

|---|---|---|

| Definition | Precise cutting method creating custom shapes by cutting through the cardboard. | Technique creating small holes or slits for easy folding or tearing without full separation. |

| Purpose | Produce complex shapes and clean edges for packaging and structural designs. | Facilitate controlled tearing, folding, or ventilation in packaging. |

| Cut Depth | Cut through entire cardboard thickness. | Partial cut, affecting only layers for fold or tear lines. |

| Applications | Boxes, inserts, custom packaging shapes, display units. | Perforated tear-off tabs, fold lines, ventilation holes. |

| Benefits | High precision, versatility, clean edges. | Ease of use, controlled tearing, cost-effective. |

| Limitations | Higher production cost, longer set-up time. | Less structural strength, limited to fold or tear lines. |

Understanding Cardboard Die-Cutting

Cardboard die-cutting involves using a custom-shaped steel blade to precisely cut out specific shapes and designs from flat cardboard sheets, enabling the creation of intricate and consistent forms for packaging, displays, and inserts. This process differs from cardboard perforation, which creates a series of small holes or cuts designed to facilitate easy folding or tearing without fully separating parts. Understanding cardboard die-cutting is crucial for manufacturers aiming to produce complex structures with clean edges and accurate dimensions that enhance both functionality and aesthetics.

What Is Cardboard Perforation?

Cardboard perforation involves creating a series of small, regularly spaced holes or cuts along a line, allowing for easy folding or tearing without damaging the structural integrity of the material. Unlike die-cutting, which removes entire sections of cardboard to form specific shapes, perforation maintains the continuous surface while enhancing flexibility and user convenience. This technique is commonly used in packaging, enabling consumers to open boxes cleanly or create detachable sections effortlessly.

Key Differences Between Die-Cutting and Perforation

Cardboard die-cutting involves cutting precise shapes and patterns with a sharp blade, creating clean and separate pieces, while perforation produces a series of small holes or slits that allow for easy tearing along a designated line. Die-cutting is ideal for producing complex designs, custom packaging, and inserts, whereas perforation facilitates user-friendly opening features such as tear strips or ventilation. The main difference lies in die-cutting removing material entirely, creating distinct shapes, whereas perforation weakens the cardboard structure without full separation.

Advantages of Die-Cutting for Cardboard Production

Die-cutting offers precise and complex shapes for cardboard production, enhancing design flexibility and customization. This method ensures clean, smooth edges that improve the structural integrity and aesthetic appeal of packaging. It also increases production efficiency by enabling rapid, repeatable cuts compared to the limited, tear-friendly lines created through perforation.

Benefits of Perforation in Cardboard Applications

Cardboard perforation enhances flexibility and ease of use by enabling clean, controlled tearing along designated lines, improving user experience in packaging and retail displays. This method preserves structural integrity while facilitating quick assembly or opening without compromising strength, unlike die-cutting which removes material entirely. Perforation also allows cost-effective customization and reduces waste, making it ideal for sustainable and efficient cardboard applications.

Use Cases for Die-Cut Cardboard

Die-cut cardboard enables precise shaping and custom designs, making it ideal for packaging solutions requiring unique forms, such as retail display boxes and custom inserts. It enhances product presentation and structural integrity, often used in branding and promotional packaging where aesthetic appeal and fit are critical. Unlike perforation, which focuses on easy folding or tearing, die-cutting facilitates complex cuts for tailored, durable cardboard constructions.

Popular Products Utilizing Perforated Cardboard

Cardboard perforation is widely used in popular products such as packaging for cereal boxes, beverage carriers, and mailers, enabling easy opening without compromising structural integrity. Unlike die-cutting, which creates distinct shapes by cutting through the cardboard, perforation involves creating a series of small holes or slits that allow sections to be torn away cleanly. This technique enhances consumer convenience and is integral in products where resealability or controlled access is required.

Cost and Efficiency: Die-Cutting vs Perforation

Cardboard die-cutting offers precise, intricate shapes and clean edges, making it ideal for customized packaging but involves higher initial equipment costs and longer setup times compared to perforation. Cardboard perforation, however, is more cost-effective for large-scale production, enhancing efficiency by allowing easy folding and tearing with minimal waste, though it provides less design flexibility. Choosing between die-cutting and perforation depends on budget constraints and the desired complexity of the cardboard product.

Choosing the Right Method for Your Cardboard Project

Cardboard die-cutting creates precise shapes and intricate designs by cutting through the entire material, ideal for custom packaging and complex structures. Cardboard perforation produces a series of small holes or slits, enabling easy folding or tear-away sections, best suited for product boxes and shipping cartons. Selecting between die-cutting and perforation depends on project needs such as structural integrity, design complexity, and functionality requirements.

Sustainability Considerations: Die-Cutting vs Perforation

Cardboard die-cutting produces cleaner edges and minimizes waste by precisely shaping materials, enhancing recycling efficiency and reducing environmental impact. In contrast, perforation weakens the structural integrity of the cardboard, potentially increasing material consumption and complicating recycling processes. Choosing die-cutting over perforation supports sustainable packaging by optimizing material use and maintaining the recyclability of cardboard products.

Cardboard die-cutting vs Cardboard perforation Infographic

materialdif.com

materialdif.com