Die-cut cardboard offers precise, customizable shapes by cutting through the material completely, providing intricate designs ideal for creative pet enclosures. Pre-scored cardboard features grooves that allow easy folding without damaging the structure, making assembly faster and more user-friendly. Choosing between die-cut and pre-scored cardboard depends on the balance of design complexity and assembly convenience for your pet project.

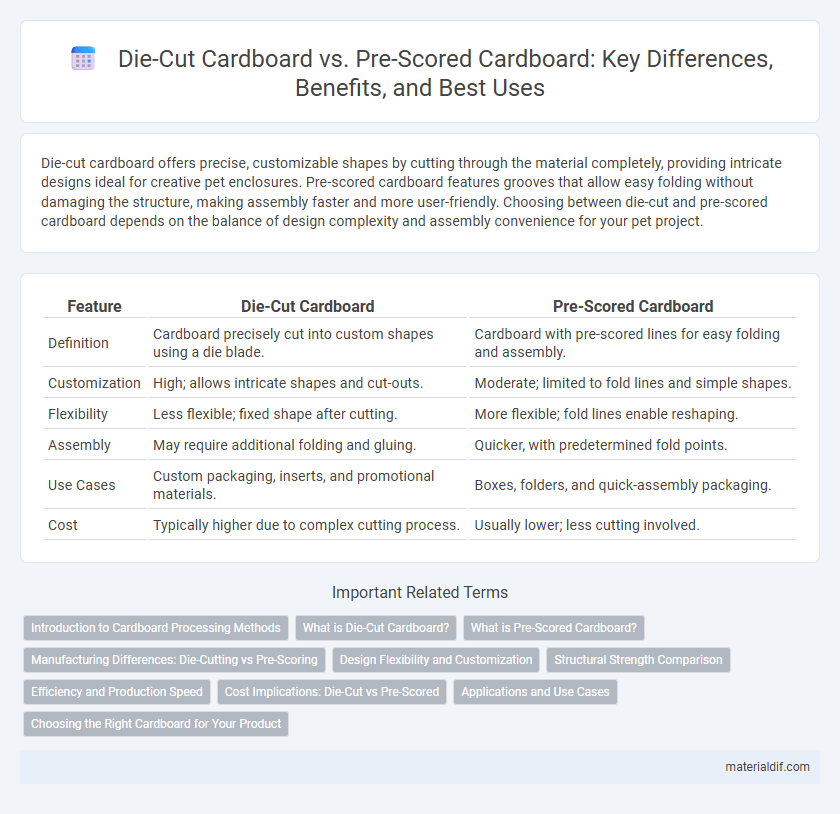

Table of Comparison

| Feature | Die-Cut Cardboard | Pre-Scored Cardboard |

|---|---|---|

| Definition | Cardboard precisely cut into custom shapes using a die blade. | Cardboard with pre-scored lines for easy folding and assembly. |

| Customization | High; allows intricate shapes and cut-outs. | Moderate; limited to fold lines and simple shapes. |

| Flexibility | Less flexible; fixed shape after cutting. | More flexible; fold lines enable reshaping. |

| Assembly | May require additional folding and gluing. | Quicker, with predetermined fold points. |

| Use Cases | Custom packaging, inserts, and promotional materials. | Boxes, folders, and quick-assembly packaging. |

| Cost | Typically higher due to complex cutting process. | Usually lower; less cutting involved. |

Introduction to Cardboard Processing Methods

Die-cut cardboard involves cutting precise shapes and patterns from cardboard sheets using custom steel blades, enabling intricate designs and structural forms for packaging and displays. Pre-scored cardboard features predefined crease lines created during manufacturing to facilitate easy folding and assembly without compromising material integrity. Both methods enhance the efficiency and functionality of cardboard processing by tailoring the material to specific design and usage requirements.

What is Die-Cut Cardboard?

Die-cut cardboard is a manufacturing process where custom shapes are cut precisely from flat sheets using a die, allowing for intricate designs and tailored packaging solutions. This method ensures clean edges and consistent dimensions, ideal for creating unique product displays or packaging with complex contours. Die-cut cardboard offers greater flexibility compared to pre-scored cardboard, which primarily features fold lines without shape alterations.

What is Pre-Scored Cardboard?

Pre-scored cardboard features precise, machine-made indentations that create fold lines, allowing for easy and accurate folding without cracking or damaging the material. This type of cardboard is ideal for packaging that requires consistent shapes and clean edges, enhancing assembly speed and product protection. Unlike die-cut cardboard, which is cut into specific shapes, pre-scored cardboard emphasizes fold precision and structural integrity.

Manufacturing Differences: Die-Cutting vs Pre-Scoring

Die-cut cardboard involves cutting out shapes from a single sheet using a die, creating precise and custom designs ideal for complex packaging. Pre-scored cardboard features predefined fold lines made by pressing into the material without cutting, facilitating easier and cleaner folding during assembly. Manufacturing die-cut cardboard requires higher tooling costs and setup time, while pre-scoring offers faster processing and reduced material waste.

Design Flexibility and Customization

Die-cut cardboard offers superior design flexibility by enabling intricate shapes and unique structural features tailored to specific packaging needs. Pre-scored cardboard simplifies folding and assembly with predefined crease lines, ideal for consistent, repeatable box designs. Customization is more extensive with die-cut processes, allowing brands to differentiate packaging through complex cuts and creative layouts.

Structural Strength Comparison

Die-cut cardboard offers enhanced structural strength due to precise cutting patterns that maintain material integrity and distribute stress evenly across folds. Pre-scored cardboard, while facilitating easier folding, often compromises durability as the scored lines create weak points susceptible to bending and tearing under pressure. In packaging applications requiring high load-bearing capacity and impact resistance, die-cut cardboard typically outperforms pre-scored variants in maintaining shape and protecting contents.

Efficiency and Production Speed

Die-cut cardboard offers precise custom shapes through cutting dies, enabling complex designs but requiring longer setup time, which can slow initial production speed. Pre-scored cardboard features pre-made fold lines that significantly enhance efficiency by simplifying assembly and reducing manual labor, leading to faster production cycles. Manufacturers often choose pre-scored cardboard for high-volume orders demanding quick turnaround, while die-cut cardboard suits intricate designs where customization outweighs speed.

Cost Implications: Die-Cut vs Pre-Scored

Die-cut cardboard typically incurs higher initial costs due to the creation of custom dies and longer setup times, making it more suitable for large production runs requiring intricate shapes. Pre-scored cardboard, with its standardized folds and reduced setup complexity, offers lower upfront expenses and faster turnaround, ideal for smaller quantities or simpler designs. Evaluating die-cut versus pre-scored cardboard depends heavily on balancing production volume, design complexity, and budget constraints for optimal cost efficiency.

Applications and Use Cases

Die-cut cardboard offers precise, custom shapes ideal for product packaging, displays, and promotional materials requiring unique designs that enhance branding. Pre-scored cardboard is best suited for packaging applications where rapid assembly and consistent folding are needed, such as shipping boxes, retail packaging, and bulk storage containers. Both types improve efficiency in manufacturing but target different needs: die-cut for aesthetic versatility and pre-scored for structural functionality.

Choosing the Right Cardboard for Your Product

Die-cut cardboard offers precise, custom shapes ideal for unique packaging designs, enhancing brand presentation and product protection. Pre-scored cardboard simplifies folding processes with predetermined crease lines, improving assembly speed and reducing labor costs. Selecting between die-cut and pre-scored options depends on product complexity, production volume, and the need for structural integrity or aesthetic appeal.

Die-cut cardboard vs Pre-scored cardboard Infographic

materialdif.com

materialdif.com