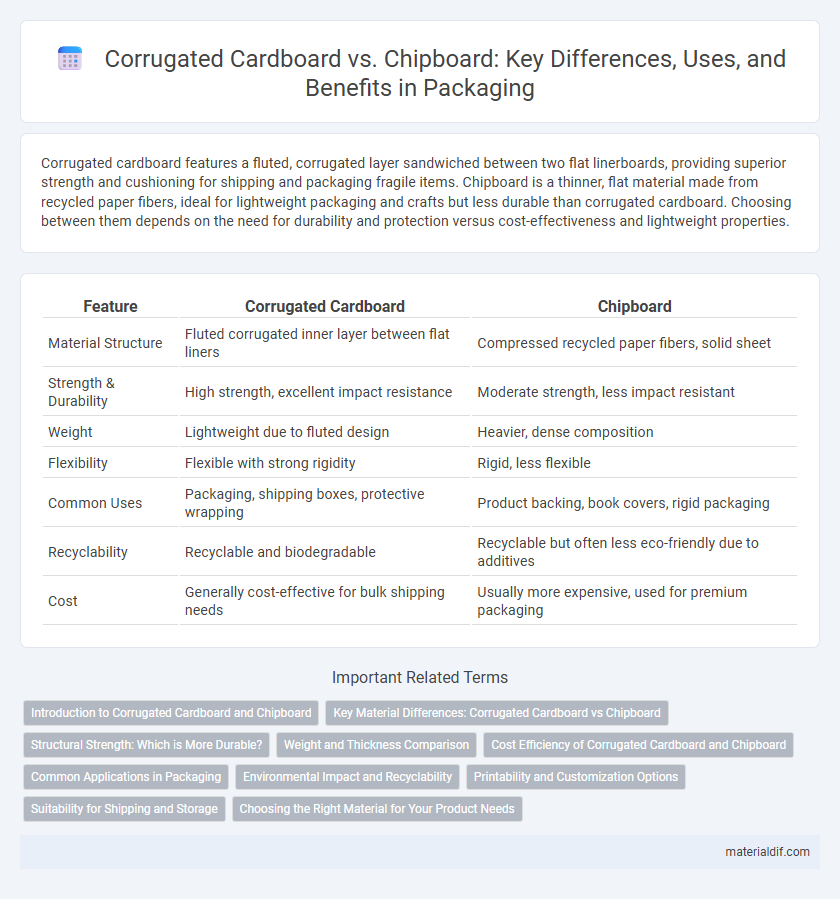

Corrugated cardboard features a fluted, corrugated layer sandwiched between two flat linerboards, providing superior strength and cushioning for shipping and packaging fragile items. Chipboard is a thinner, flat material made from recycled paper fibers, ideal for lightweight packaging and crafts but less durable than corrugated cardboard. Choosing between them depends on the need for durability and protection versus cost-effectiveness and lightweight properties.

Table of Comparison

| Feature | Corrugated Cardboard | Chipboard |

|---|---|---|

| Material Structure | Fluted corrugated inner layer between flat liners | Compressed recycled paper fibers, solid sheet |

| Strength & Durability | High strength, excellent impact resistance | Moderate strength, less impact resistant |

| Weight | Lightweight due to fluted design | Heavier, dense composition |

| Flexibility | Flexible with strong rigidity | Rigid, less flexible |

| Common Uses | Packaging, shipping boxes, protective wrapping | Product backing, book covers, rigid packaging |

| Recyclability | Recyclable and biodegradable | Recyclable but often less eco-friendly due to additives |

| Cost | Generally cost-effective for bulk shipping needs | Usually more expensive, used for premium packaging |

Introduction to Corrugated Cardboard and Chipboard

Corrugated cardboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength and durability for packaging and shipping applications. Chipboard, made from recycled paper fibers compressed into a dense, flat sheet, offers a lightweight and cost-effective option for products requiring less structural support. Both materials serve distinct purposes in packaging, with corrugated cardboard preferred for heavy-duty uses and chipboard for lightweight, decorative, or rigid packaging solutions.

Key Material Differences: Corrugated Cardboard vs Chipboard

Corrugated cardboard consists of three layers: an inner liner, outer liner, and a fluted corrugated medium, providing superior strength and cushioning ideal for shipping and packaging. Chipboard, made from recycled paper pulp compressed into a single flat layer, offers a denser but less durable option, commonly used for book covers and backing boards. The key material difference lies in corrugated cardboard's multi-layer structure enhancing rigidity and impact resistance, while chipboard's uniform composition prioritizes smoothness and firmness for lighter protective applications.

Structural Strength: Which is More Durable?

Corrugated cardboard offers superior structural strength due to its fluted inner layer, providing enhanced durability and cushioning compared to chipboard's solid but flatter composition. Chipboard, made from recycled paper pressed into sheets, is less resistant to impact and bending under heavy loads, making it less ideal for packaging fragile or heavy items. For applications demanding robust protection and durability, corrugated cardboard is the more reliable choice.

Weight and Thickness Comparison

Corrugated cardboard typically weighs between 100 to 150 grams per square meter and has a thickness ranging from 1.5 to 5 millimeters, making it ideal for packaging that requires strength and cushioning. Chipboard is denser, with weights often exceeding 200 grams per square meter and thickness varying from 0.5 to 4 millimeters, offering a sturdier but less flexible material suited for rigid applications. The significant difference in structure means corrugated cardboard has a layered design with fluted paper, contributing to greater strength-to-weight ratio compared to the solid, compressed fiber structure of chipboard.

Cost Efficiency of Corrugated Cardboard and Chipboard

Corrugated cardboard offers superior cost efficiency due to its lightweight structure and high durability, reducing shipping and packaging expenses. Chipboard, while generally cheaper per sheet, lacks the strength needed for protective packaging, often leading to higher replacement costs. Businesses prioritize corrugated cardboard for long-term savings through reduced damage rates and transportation costs.

Common Applications in Packaging

Corrugated cardboard is widely used in shipping and protective packaging due to its durability and cushioning properties, making it ideal for boxes and cartons that require strength and impact resistance. Chipboard, being thinner and more rigid, is primarily utilized in product packaging like folding cartons, backing for notepads, and small retail boxes where a smooth surface and printability are essential. Both materials serve crucial roles in packaging, with corrugated cardboard excelling in heavy-duty applications and chipboard favored for lightweight, visually appealing packaging solutions.

Environmental Impact and Recyclability

Corrugated cardboard, composed of multiple layers including a fluted inner layer, offers superior recyclability by being compatible with standard paper recycling processes and is more widely accepted in recycling programs. Chipboard, made from reclaimed paper fibers that are pressed together, tends to have lower durability and can contain coatings or additives that complicate recycling efforts and reduce its environmental benefits. The higher fiber quality and structure of corrugated cardboard contribute to a more sustainable lifecycle, making it the preferred choice for eco-friendly packaging solutions.

Printability and Customization Options

Corrugated cardboard offers superior printability due to its smooth outer liner, enabling vibrant graphics and high-resolution branding, making it ideal for packaging that demands visual appeal. Chipboard, being denser and more rigid but less smooth, provides limited print quality and fewer customization options, often requiring additional coatings or treatments for enhanced visual effects. For brands prioritizing print detail and extensive customization, corrugated cardboard is the preferred choice over chipboard.

Suitability for Shipping and Storage

Corrugated cardboard offers superior strength and cushioning, making it ideal for shipping fragile or heavy items due to its fluted inner layer that absorbs shocks and resists crushing. Chipboard, being thinner and less durable, suits lightweight packaging and short-term storage where protection from impact is minimal. For long-distance shipping and heavy-duty storage, corrugated cardboard ensures better product safety and structural integrity.

Choosing the Right Material for Your Product Needs

Corrugated cardboard features a fluted middle layer between two linerboards, providing superior strength and cushioning, making it ideal for shipping and packaging fragile items. Chipboard, a dense and flat material made from recycled paper pulp, offers rigidity and smooth surface finish, suitable for lightweight packaging or printing applications. Selecting the right material depends on product weight, durability requirements, and budget constraints, with corrugated cardboard favored for heavy-duty protection and chipboard chosen for cost-effective, aesthetic packaging.

Corrugated Cardboard vs Chipboard Infographic

materialdif.com

materialdif.com