Boxboard offers superior strength and durability compared to chipboard, making it ideal for packaging applications that require protection and structure. Chipboard, often made from recycled paper, is lighter and more affordable, but less robust, commonly used for backing, inserts, or lightweight packaging. Choosing between boxboard and chipboard depends on the balance needed between cost-efficiency and product protection.

Table of Comparison

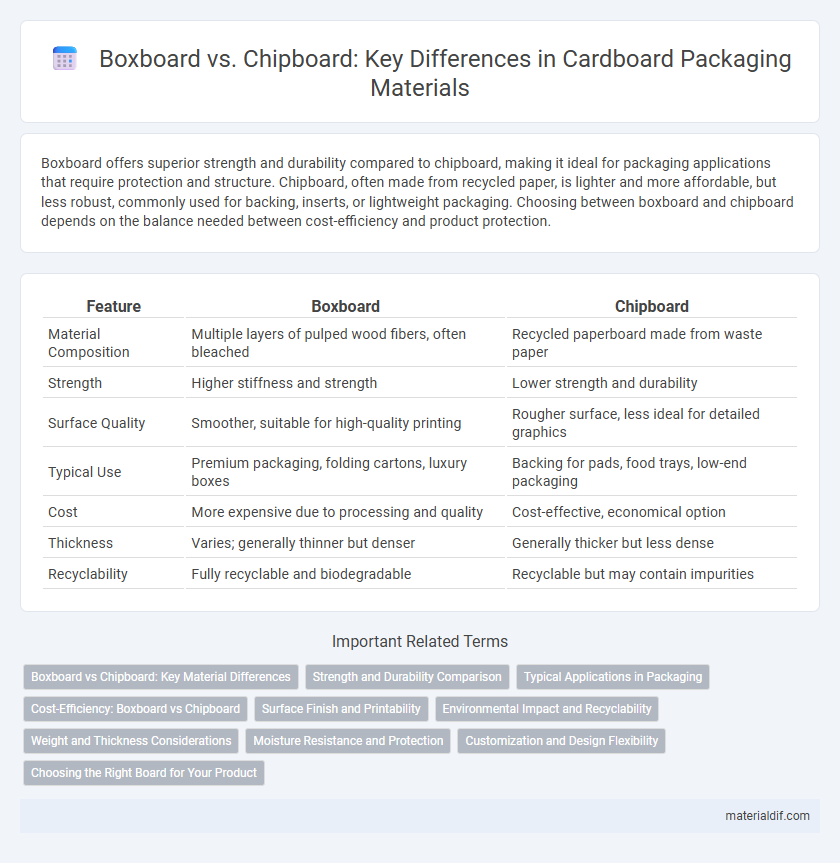

| Feature | Boxboard | Chipboard |

|---|---|---|

| Material Composition | Multiple layers of pulped wood fibers, often bleached | Recycled paperboard made from waste paper |

| Strength | Higher stiffness and strength | Lower strength and durability |

| Surface Quality | Smoother, suitable for high-quality printing | Rougher surface, less ideal for detailed graphics |

| Typical Use | Premium packaging, folding cartons, luxury boxes | Backing for pads, food trays, low-end packaging |

| Cost | More expensive due to processing and quality | Cost-effective, economical option |

| Thickness | Varies; generally thinner but denser | Generally thicker but less dense |

| Recyclability | Fully recyclable and biodegradable | Recyclable but may contain impurities |

Boxboard vs Chipboard: Key Material Differences

Boxboard typically features multiple layers of wood pulp, resulting in a lightweight, sturdy material ideal for packaging and printing applications. Chipboard, made from recycled paperboard scrap, is denser and less smooth, offering a cost-effective solution for backing, folders, and book covers. The distinct fiber content and manufacturing process give boxboard a finer surface and higher strength, while chipboard emphasizes durability and affordability.

Strength and Durability Comparison

Boxboard offers superior strength and durability compared to chipboard due to its multi-ply layers and higher density composition, making it ideal for packaging applications requiring robust protection. Chipboard, made from recycled paper fibers with a single-layer structure, tends to be less rigid and more prone to bending under stress. The enhanced structural integrity of boxboard supports heavier loads and better resistance to impact, moisture, and wear.

Typical Applications in Packaging

Boxboard is commonly used for packaging lightweight consumer goods such as cereal boxes, frozen food cartons, and cosmetic packaging due to its smooth surface and excellent printability. Chipboard is typically employed for structural support in packaging applications like backing for notepads, shoe boxes, and product trays, providing stiffness and durability without the need for a high-quality finish. Both materials contribute to eco-friendly packaging solutions by being recyclable and often made from recycled fibers.

Cost-Efficiency: Boxboard vs Chipboard

Boxboard offers a cost-efficient solution for lightweight packaging with its thinner composition and smooth surface, making it ideal for retail boxes and printing applications. Chipboard, made from recycled paper pulp, provides a more affordable option for structural packaging and backing materials, excelling in bulk production where durability is less critical. The choice between boxboard and chipboard hinges on balancing manufacturing costs with the required strength and finish quality for the intended use.

Surface Finish and Printability

Boxboard offers a smoother surface finish compared to chipboard, making it ideal for high-quality printing applications. Its uniform texture enhances ink adhesion, resulting in vibrant and crisp print images. Chipboard, often rougher and more porous, tends to absorb ink unevenly, which can compromise print clarity and overall visual appeal.

Environmental Impact and Recyclability

Boxboard typically has a higher environmental sustainability profile than chipboard due to its easier recyclability and fewer additives in production. Chipboard often contains more recycled content but can include contaminants like adhesives and coatings that complicate recycling processes. Choosing boxboard reduces landfill waste and supports circular economy practices through efficient material recovery and reuse.

Weight and Thickness Considerations

Boxboard generally offers a higher weight and greater thickness compared to chipboard, providing enhanced durability and rigidity for packaging applications. Chipboard is typically lighter and thinner, making it more suitable for lightweight packaging and economical printing. Weight and thickness variations between boxboard and chipboard significantly influence their suitability for different structural and functional requirements in packaging design.

Moisture Resistance and Protection

Boxboard offers superior moisture resistance compared to chipboard due to its denser fiber composition and coated surface, making it ideal for packaging sensitive products requiring enhanced protection. Chipboard, typically made from recycled paper with lower density, provides less resistance to moisture and is more prone to warping and weakening when exposed to humidity. For applications demanding reliable structural integrity and moisture barrier properties, boxboard is preferred over chipboard.

Customization and Design Flexibility

Boxboard offers greater customization and design flexibility compared to chipboard due to its smooth surface and superior printability, making it ideal for high-quality packaging and intricate graphics. Chipboard, typically made from recycled paper fibers, is more rigid but less receptive to detailed printing and complex finishes, limiting design options. When project requirements demand vibrant colors, embossing, or specialty coatings, boxboard is the preferred material to achieve versatile and visually appealing packaging solutions.

Choosing the Right Board for Your Product

Boxboard offers superior strength and is ideal for packaging that requires durability and protection, such as food containers and cosmetics. Chipboard, made from recycled paper, provides an eco-friendly and cost-effective option suited for lightweight packaging and backing applications. Selecting the right board depends on product weight, desired rigidity, and sustainability goals to ensure optimal performance and presentation.

Boxboard vs Chipboard Infographic

materialdif.com

materialdif.com