Wax-coated cardboard offers water resistance by applying a thin layer of wax, making it ideal for packaging moist or perishable items, while laminated cardboard provides enhanced durability and a glossy finish through a plastic film layer, improving strength and aesthetic appeal. Despite wax coatings being biodegradable, laminated cardboard often resists moisture and chemicals better but can be more challenging to recycle due to its plastic components. Choosing between these types depends on specific packaging requirements, including environmental impact, moisture protection, and product presentation.

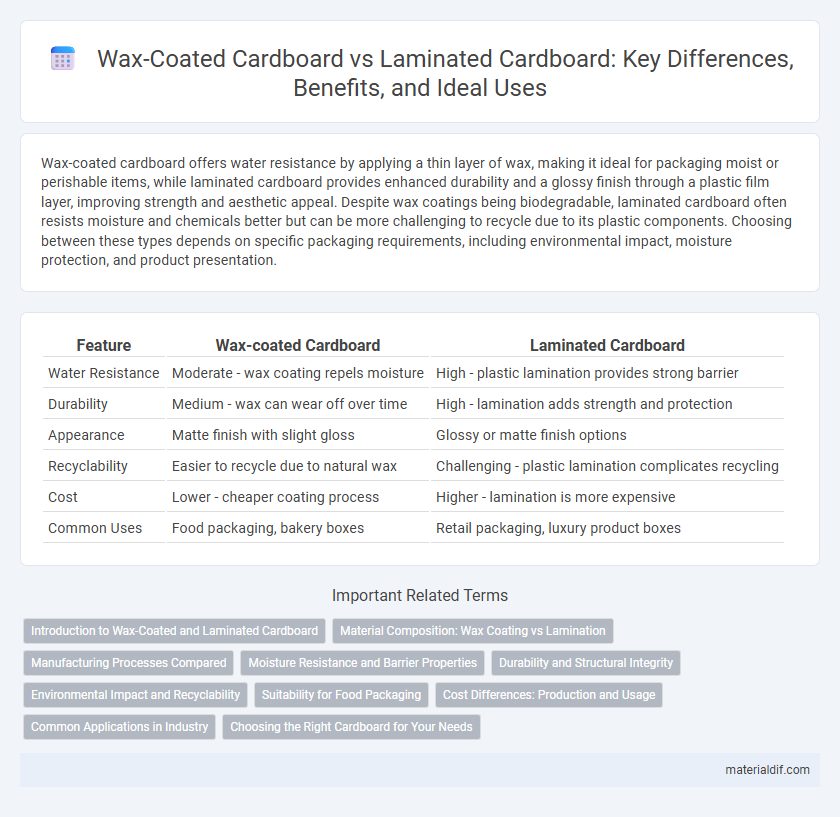

Table of Comparison

| Feature | Wax-coated Cardboard | Laminated Cardboard |

|---|---|---|

| Water Resistance | Moderate - wax coating repels moisture | High - plastic lamination provides strong barrier |

| Durability | Medium - wax can wear off over time | High - lamination adds strength and protection |

| Appearance | Matte finish with slight gloss | Glossy or matte finish options |

| Recyclability | Easier to recycle due to natural wax | Challenging - plastic lamination complicates recycling |

| Cost | Lower - cheaper coating process | Higher - lamination is more expensive |

| Common Uses | Food packaging, bakery boxes | Retail packaging, luxury product boxes |

Introduction to Wax-Coated and Laminated Cardboard

Wax-coated cardboard is treated with a thin layer of wax to enhance water resistance and durability, making it ideal for packaging moist or perishable goods. Laminated cardboard incorporates a plastic or polymer film layer, providing superior strength, moisture protection, and a glossy finish suited for premium packaging and long-term storage. Both materials improve the standard cardboard's functionality but differ significantly in their protective properties and cost implications.

Material Composition: Wax Coating vs Lamination

Wax-coated cardboard features a thin layer of paraffin or beeswax that is applied to the surface, providing moisture resistance through its hydrophobic properties. Laminated cardboard consists of multiple layers bonded with plastic films or resins, enhancing durability, moisture barrier, and structural strength. The key difference lies in wax-coated cardboard relying on wax for water repellency, while laminated cardboard integrates synthetic materials for superior protection and rigidity.

Manufacturing Processes Compared

Wax-coated cardboard involves applying a thin layer of paraffin or beeswax during production to enhance moisture resistance and grease protection, typically achieved through a dipping or spraying process. Laminated cardboard manufacturing incorporates multiple layers bonded together using adhesives, often combining paperboard with plastic films or foil materials to improve durability, strength, and barrier properties. The wax-coating process is generally simpler and less costly, whereas lamination requires specialized equipment and offers superior structural integrity and resistance to environmental factors.

Moisture Resistance and Barrier Properties

Wax-coated cardboard offers moderate moisture resistance by providing a water-repellent surface that prevents liquid absorption but may degrade under prolonged exposure. Laminated cardboard features a plastic film layer that delivers superior moisture resistance and enhanced barrier properties, effectively blocking water vapor, grease, and contaminants. These differences make laminated cardboard more suitable for packaging applications requiring long-term protection against moisture and spoilage.

Durability and Structural Integrity

Wax-coated cardboard offers water resistance by creating a moisture barrier, enhancing durability in humid and wet conditions while maintaining flexibility. Laminated cardboard provides superior structural integrity through multiple bonded layers, increasing strength and resistance to crushing and impact. For long-term durability and heavy-duty use, laminated cardboard outperforms wax-coated options due to its reinforced composition.

Environmental Impact and Recyclability

Wax-coated cardboard offers water resistance but is less environmentally friendly due to the difficulty of recycling caused by the wax coating, which contaminates paper recycling streams and often leads to landfill disposal. Laminated cardboard, especially when using polyethylene or plastic laminates, poses significant recycling challenges because the layers must be separated before processing, resulting in limited recyclability and higher environmental impact. Both materials present obstacles for circular waste management, but innovations in biodegradable coatings and mono-material laminates are improving the eco-friendliness of cardboard packaging.

Suitability for Food Packaging

Wax-coated cardboard provides excellent moisture resistance and grease protection, making it ideal for packaging items like baked goods and fast food. Laminated cardboard offers enhanced durability and barrier properties against oxygen and odors, suitable for longer shelf-life products such as frozen foods and beverages. Both materials ensure food safety, but selection depends on the required moisture barrier and product storage duration.

Cost Differences: Production and Usage

Wax-coated cardboard typically incurs lower production costs due to simpler manufacturing processes and readily available wax materials, making it a cost-effective choice for packaging that requires moisture resistance. Laminated cardboard involves higher production expenses as it integrates multiple layers and specialized adhesives, enhancing durability and protection but increasing material and labor costs. Usage costs also differ, with wax-coated cardboard favored for disposable or short-term applications, while laminated cardboard is more cost-efficient for long-term or heavy-duty packaging despite its higher initial investment.

Common Applications in Industry

Wax-coated cardboard is widely used in the food packaging industry for its moisture resistance, making it ideal for packaging fresh produce, frozen goods, and takeaway containers. Laminated cardboard, featuring a plastic or aluminum layer, is preferred in electronics and luxury product packaging due to its enhanced durability and superior barrier against moisture and contaminants. Both materials serve critical roles in protecting contents while meeting specific industry requirements for strength and preservation.

Choosing the Right Cardboard for Your Needs

Wax-coated cardboard offers superior moisture resistance, making it ideal for packaging products exposed to humidity or water, such as fresh produce and frozen goods. Laminated cardboard provides enhanced durability and a smooth surface for high-quality printing, suitable for premium packaging and retail displays. Selecting the right cardboard depends on balancing moisture protection and visual appeal based on specific product requirements.

Wax-coated cardboard vs Laminated cardboard Infographic

materialdif.com

materialdif.com