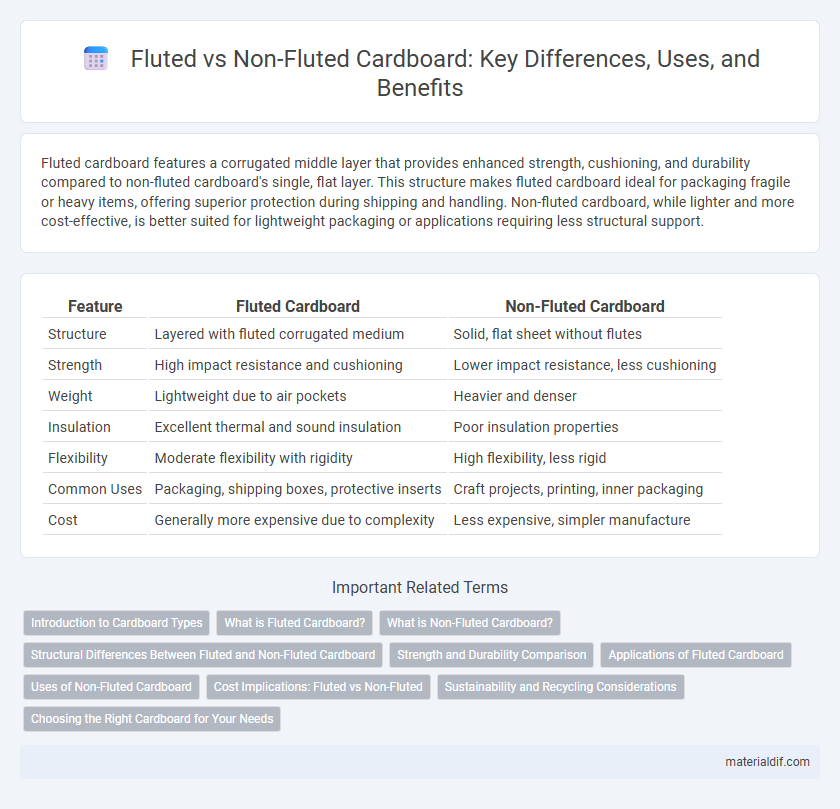

Fluted cardboard features a corrugated middle layer that provides enhanced strength, cushioning, and durability compared to non-fluted cardboard's single, flat layer. This structure makes fluted cardboard ideal for packaging fragile or heavy items, offering superior protection during shipping and handling. Non-fluted cardboard, while lighter and more cost-effective, is better suited for lightweight packaging or applications requiring less structural support.

Table of Comparison

| Feature | Fluted Cardboard | Non-Fluted Cardboard |

|---|---|---|

| Structure | Layered with fluted corrugated medium | Solid, flat sheet without flutes |

| Strength | High impact resistance and cushioning | Lower impact resistance, less cushioning |

| Weight | Lightweight due to air pockets | Heavier and denser |

| Insulation | Excellent thermal and sound insulation | Poor insulation properties |

| Flexibility | Moderate flexibility with rigidity | High flexibility, less rigid |

| Common Uses | Packaging, shipping boxes, protective inserts | Craft projects, printing, inner packaging |

| Cost | Generally more expensive due to complexity | Less expensive, simpler manufacture |

Introduction to Cardboard Types

Fluted cardboard features a corrugated inner layer that enhances strength, cushioning, and durability, making it ideal for packaging fragile items. Non-fluted cardboard, often referred to as chipboard or paperboard, consists of a single solid layer, offering a smooth surface suitable for printing and lightweight applications. Understanding these cardboard types helps optimize material choice based on protection needs and design requirements.

What is Fluted Cardboard?

Fluted cardboard consists of a corrugated layer sandwiched between two flat linerboards, providing enhanced strength and cushioning. This structure creates air pockets that improve shock absorption and durability, making it ideal for packaging fragile items. Non-fluted cardboard lacks this corrugated middle layer, resulting in less rigidity and protection compared to fluted cardboard.

What is Non-Fluted Cardboard?

Non-fluted cardboard is a type of paperboard without the characteristic corrugated inner layer found in fluted cardboard, resulting in a flat, smooth surface ideal for printing and packaging applications requiring clear graphics and clean finishes. It is often used for lightweight packaging, cartons, book covers, and folding boxes where structural strength provided by fluting is unnecessary. Its thin, non-corrugated composition makes it more flexible but less durable compared to fluted cardboard, which combines outer liners and a fluted medium for enhanced cushioning and rigidity.

Structural Differences Between Fluted and Non-Fluted Cardboard

Fluted cardboard features a corrugated inner layer sandwiched between two flat linerboards, providing enhanced strength, cushioning, and rigidity ideal for packaging and shipping. Non-fluted cardboard, or paperboard, consists of a single solid layer, resulting in a smoother surface but less durability and structural support compared to fluted varieties. This fundamental difference in construction impacts load-bearing capacity, insulation properties, and resistance to bending or crushing.

Strength and Durability Comparison

Fluted cardboard features a corrugated layer between flat liners, providing enhanced strength and superior durability compared to non-fluted cardboard, which lacks this structural reinforcement. The fluted structure absorbs shocks and resists bending, making it ideal for heavy-duty packaging and shipping applications. In contrast, non-fluted cardboard offers less impact resistance and is more prone to crushing under pressure, limiting its use to lightweight or protective wrapping purposes.

Applications of Fluted Cardboard

Fluted cardboard is extensively used in packaging applications due to its superior strength, cushioning properties, and ability to protect fragile items during shipping. It is ideal for producing corrugated boxes, protective inserts, and shipping containers that require durability and resistance to compression. Common industries utilizing fluted cardboard include e-commerce, food distribution, and electronics, where product safety and efficient stacking are critical.

Uses of Non-Fluted Cardboard

Non-fluted cardboard, characterized by its flat, smooth surface, is extensively used in applications requiring precise printing and a uniform appearance, such as greeting cards, book covers, and product packaging for luxury items. Its rigidity and smooth texture make it ideal for crafting, signage, and folders where durability and aesthetic quality are essential. Unlike fluted cardboard, non-fluted variants provide a stable surface ideal for detailed graphic designs and high-resolution images.

Cost Implications: Fluted vs Non-Fluted

Fluted cardboard typically offers cost advantages due to its lightweight structure and efficient use of raw materials, reducing transportation and production expenses. Non-fluted cardboard, by contrast, usually incurs higher costs as it requires denser, solid sheets that are heavier and more material-intensive. Choosing fluted cardboard can lead to significant savings in packaging budgets, especially for bulk shipments where reduced weight lowers freight charges.

Sustainability and Recycling Considerations

Fluted cardboard, composed of an inner corrugated layer sandwiched between flat linerboards, offers enhanced strength while maintaining recyclability compared to non-fluted cardboard, which is typically a single flat sheet. The air pockets within fluted cardboard improve insulation and cushioning, reducing material use in packaging and supporting sustainability by minimizing waste. Both materials are widely recyclable, but fluted cardboard's structure often requires separation from non-fluted liners during recycling, emphasizing the importance of proper disposal practices to optimize material recovery and environmental benefits.

Choosing the Right Cardboard for Your Needs

Fluted cardboard offers enhanced strength and cushioning due to its corrugated inner layer, making it ideal for packaging fragile items and providing superior protection during shipping. Non-fluted cardboard, being flat and smooth, is better suited for applications requiring a clean print surface or lightweight packaging where structural support is less critical. Selecting the right cardboard depends on balancing durability needs with presentation requirements to ensure optimal performance and cost-efficiency.

Fluted cardboard vs Non-fluted cardboard Infographic

materialdif.com

materialdif.com