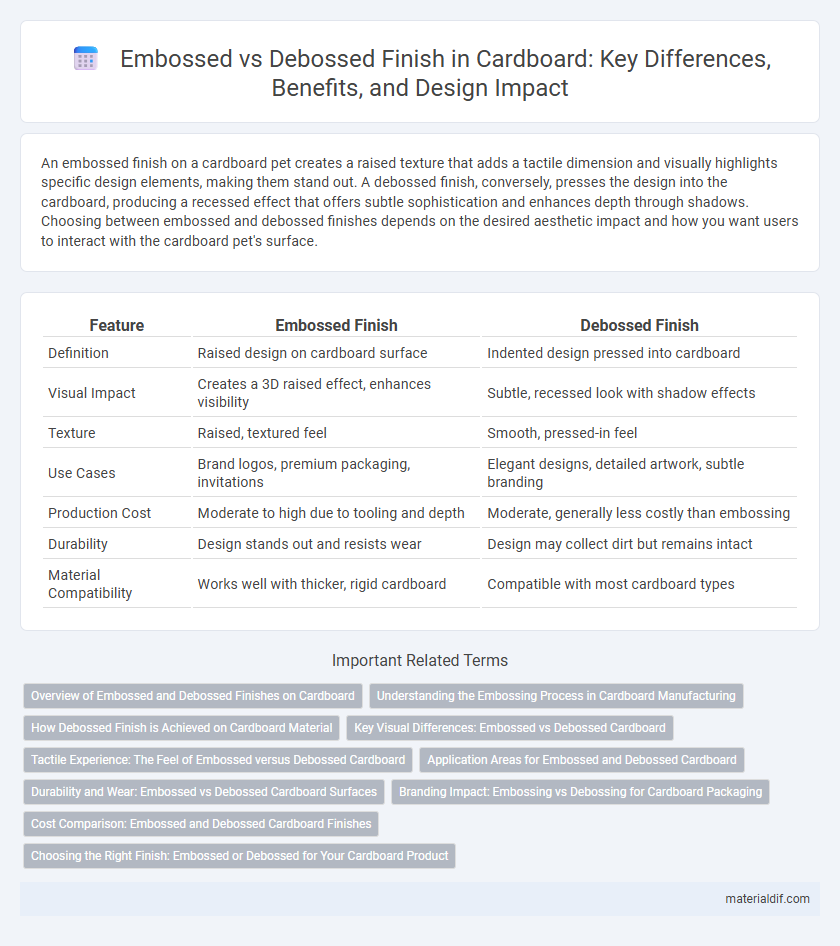

An embossed finish on a cardboard pet creates a raised texture that adds a tactile dimension and visually highlights specific design elements, making them stand out. A debossed finish, conversely, presses the design into the cardboard, producing a recessed effect that offers subtle sophistication and enhances depth through shadows. Choosing between embossed and debossed finishes depends on the desired aesthetic impact and how you want users to interact with the cardboard pet's surface.

Table of Comparison

| Feature | Embossed Finish | Debossed Finish |

|---|---|---|

| Definition | Raised design on cardboard surface | Indented design pressed into cardboard |

| Visual Impact | Creates a 3D raised effect, enhances visibility | Subtle, recessed look with shadow effects |

| Texture | Raised, textured feel | Smooth, pressed-in feel |

| Use Cases | Brand logos, premium packaging, invitations | Elegant designs, detailed artwork, subtle branding |

| Production Cost | Moderate to high due to tooling and depth | Moderate, generally less costly than embossing |

| Durability | Design stands out and resists wear | Design may collect dirt but remains intact |

| Material Compatibility | Works well with thicker, rigid cardboard | Compatible with most cardboard types |

Overview of Embossed and Debossed Finishes on Cardboard

Embossed finish on cardboard creates a raised design that adds texture and visual interest, enhancing brand perception and tactile experience. Debossed finish involves pressing the design into the cardboard surface, producing a recessed effect that provides subtle elegance and sophistication. Both techniques improve the packaging's aesthetic appeal and can be combined with printing or foil stamping for a premium presentation.

Understanding the Embossing Process in Cardboard Manufacturing

The embossing process in cardboard manufacturing involves creating raised patterns or designs by pressing the material between a male and female die, enhancing texture and visual appeal. This technique increases tactile engagement and allows for intricate branding or decorative elements, making packaging more attractive and distinct. Compared to debossing, which indents the design into the surface, embossing adds dimension by elevating features, adding a premium feel to cardboard products.

How Debossed Finish is Achieved on Cardboard Material

A debossed finish on cardboard is created by pressing an engraved die into the material's surface, producing a recessed design that adds texture and depth without raising the surface. This technique requires precise pressure and alignment to ensure the indentations are clean and consistent, enhancing the tactile and visual appeal of packaging or printed products. Debossing works best on thicker cardboard stocks, allowing for sharp detail retention and durability in the finished product.

Key Visual Differences: Embossed vs Debossed Cardboard

Embossed cardboard features raised designs that create a three-dimensional effect by pushing the material outward, enhancing tactile appeal and visual depth. Debossed cardboard, in contrast, displays recessed patterns pressed into the surface, offering subtle texture and shadow effects without protrusion. These key visual differences influence packaging aesthetics, with embossing providing a bold, standout look while debossing delivers a refined, understated elegance.

Tactile Experience: The Feel of Embossed versus Debossed Cardboard

Embossed cardboard features raised designs that create a prominent, textured surface, providing a tactile feel that enhances grip and visual appeal. In contrast, debossed cardboard has recessed impressions that offer a subtle, refined texture, allowing for understated detailing that emphasizes depth and craftsmanship. The choice between embossed and debossed finishes significantly influences the sensory interaction, impacting packaging perception and consumer engagement.

Application Areas for Embossed and Debossed Cardboard

Embossed cardboard is commonly used in premium packaging for cosmetics, electronics, and luxury goods to create raised textures that enhance brand appeal and tactile experience. Debossed cardboard finds its application in business cards, invitations, and branding materials where subtle, indented impressions convey sophistication and understated elegance. Both finishes are integral to product differentiation in retail packaging, with embossed enhancing visual impact and debossed adding depth and tactility to printed designs.

Durability and Wear: Embossed vs Debossed Cardboard Surfaces

Embossed cardboard surfaces feature raised patterns that enhance durability by resisting scratches and wear more effectively than debossed finishes, which have recessed designs prone to accumulating dirt and damage over time. The elevated texture of embossed finishes provides increased protection against abrasion, making them ideal for packaging that requires frequent handling. In contrast, debossed surfaces may show wear faster due to their indentations, which can trap grime and weaken structural integrity under stress.

Branding Impact: Embossing vs Debossing for Cardboard Packaging

Embossed finishes on cardboard packaging create raised designs that enhance brand visibility through tactile engagement and elevated aesthetics, making logos and messages stand out prominently. Debossed finishes, characterized by recessed impressions, offer a subtle, sophisticated branding approach that conveys elegance and premium quality while maintaining minimal surface disruption. Choosing between embossing and debossing impacts consumer perception by balancing visual prominence with tactile subtlety, crucial for strong brand identity in competitive markets.

Cost Comparison: Embossed and Debossed Cardboard Finishes

Embossed cardboard finishes generally incur higher production costs due to the intricate raised designs requiring specialized embossing plates and extended press times. Debossed finishes tend to be more cost-effective as the impressions are recessed, often involving simpler tooling and faster processing. Budget considerations for packaging projects often favor debossed finishes when balancing aesthetic appeal with cost efficiency.

Choosing the Right Finish: Embossed or Debossed for Your Cardboard Product

Choosing between embossed and debossed finishes for your cardboard product depends on the desired tactile effect and visual impact. Embossed finish raises the design above the surface, creating a prominent, eye-catching texture that enhances branding through a luxurious feel. Debossed finish impresses the design into the cardboard, offering a subtle, elegant look ideal for understated sophistication and refined packaging.

Embossed finish vs Debossed finish Infographic

materialdif.com

materialdif.com