Rigid cardboard offers superior strength and durability, making it ideal for packaging heavy or fragile items, whereas flexible cardboard provides easier bending and folding, suitable for lightweight packaging and creative projects. The density and thickness differences between rigid and flexible cardboard impact their structural integrity and application versatility. Choosing the right type depends on the specific packaging needs, balancing protection with adaptability.

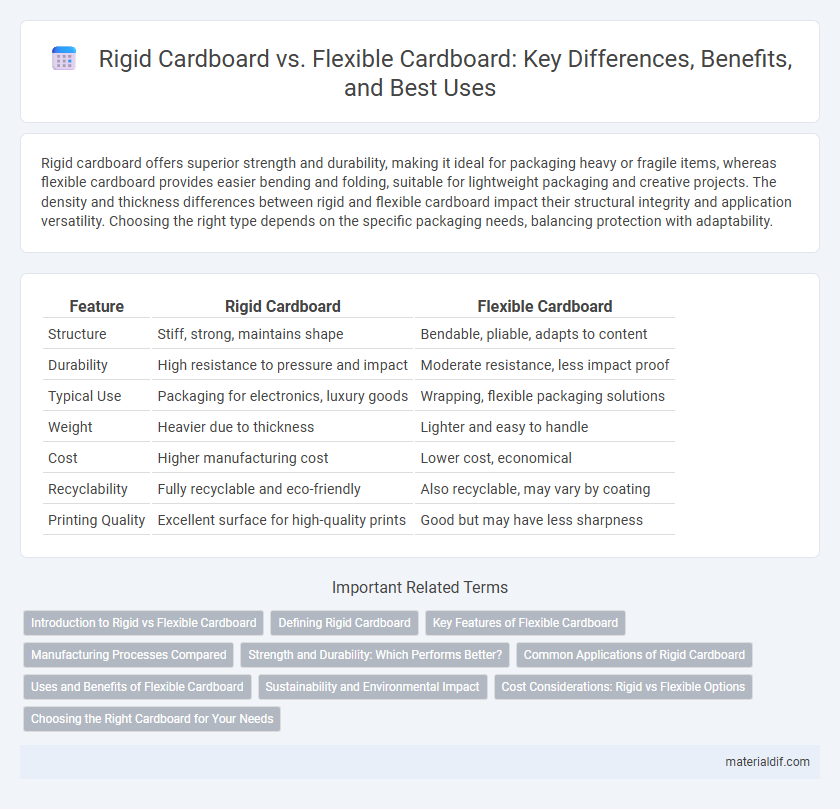

Table of Comparison

| Feature | Rigid Cardboard | Flexible Cardboard |

|---|---|---|

| Structure | Stiff, strong, maintains shape | Bendable, pliable, adapts to content |

| Durability | High resistance to pressure and impact | Moderate resistance, less impact proof |

| Typical Use | Packaging for electronics, luxury goods | Wrapping, flexible packaging solutions |

| Weight | Heavier due to thickness | Lighter and easy to handle |

| Cost | Higher manufacturing cost | Lower cost, economical |

| Recyclability | Fully recyclable and eco-friendly | Also recyclable, may vary by coating |

| Printing Quality | Excellent surface for high-quality prints | Good but may have less sharpness |

Introduction to Rigid vs Flexible Cardboard

Rigid cardboard features a thicker, more durable structure commonly used for packaging heavy or fragile items, providing superior protection and stability. Flexible cardboard, often thinner and more pliable, is ideal for lightweight packaging and applications requiring easy folding or bending. Understanding the key differences in composition and usage between rigid and flexible cardboard helps optimize material selection for specific packaging needs.

Defining Rigid Cardboard

Rigid cardboard is a dense, thick material known for its durability and strength, commonly used in packaging that requires enhanced protection such as book covers, backing boards, and presentation boxes. Unlike flexible cardboard, which bends easily and is suitable for wrapping or folding applications, rigid cardboard maintains its shape under pressure and resists bending. Its composition typically involves multiple layers of sturdy pulp fibers pressed tightly together, contributing to its structural integrity and impact resistance.

Key Features of Flexible Cardboard

Flexible cardboard is characterized by its lightweight structure, enhanced bendability, and ability to absorb shocks without cracking, making it ideal for packaging items with irregular shapes. Its porous texture allows for better cushioning and insulation, while maintaining durability during handling and transportation. The material's compatibility with various printing techniques ensures high-quality branding and labeling for consumer appeal.

Manufacturing Processes Compared

Rigid cardboard manufacturing involves pressing multiple layers of paperboard under high pressure and heat to create a dense, sturdy material ideal for packaging heavy items. Flexible cardboard, also known as corrugated cardboard, is produced by bonding a fluted corrugated sheet between two flat linerboards, providing cushioning and light-weight strength. The manufacturing process of rigid cardboard is more labor-intensive with longer drying times, while flexible cardboard benefits from faster production cycles due to its layered construction design.

Strength and Durability: Which Performs Better?

Rigid cardboard offers superior strength and durability due to its thicker composition and reinforced layers, making it ideal for heavy-duty packaging and structural applications. Flexible cardboard, while less robust, provides better adaptability and resilience for bending or folding tasks but sacrifices long-term durability under heavy stress. For applications requiring maximum protection and load-bearing capacity, rigid cardboard consistently outperforms flexible cardboard in strength and durability metrics.

Common Applications of Rigid Cardboard

Rigid cardboard, known for its sturdy and durable properties, is commonly used in packaging high-value or fragile items such as electronics, luxury goods, and pharmaceuticals. Its structural integrity provides excellent protection during shipping and handling, making it ideal for product display boxes and custom retail packaging. Industries that require enhanced product safety and presentation often prefer rigid cardboard over flexible alternatives due to its superior cushioning and resistance to deformation.

Uses and Benefits of Flexible Cardboard

Flexible cardboard offers superior versatility in packaging applications, adapting easily to irregular shapes and providing excellent cushioning for fragile items. Its lightweight nature reduces shipping costs while maintaining durability, making it ideal for consumer goods, food packaging, and promotional materials. This adaptability supports sustainable practices by enabling efficient recycling and reducing material waste compared to rigid cardboard.

Sustainability and Environmental Impact

Rigid cardboard offers enhanced durability and protection, making it ideal for long-term use and reducing the need for frequent replacements, thus minimizing waste. Flexible cardboard, often lighter and less dense, requires less material and energy to produce, contributing to a lower carbon footprint during manufacturing. Both types are recyclable, but optimizing the balance between rigidity and flexibility can lead to more sustainable packaging solutions by extending product lifespan and reducing environmental impact.

Cost Considerations: Rigid vs Flexible Options

Rigid cardboard typically incurs higher production costs due to thicker materials and increased durability, making it suitable for premium packaging. Flexible cardboard offers a more cost-effective solution with lower material and manufacturing expenses, ideal for lightweight and bulk packaging needs. Choosing between rigid and flexible cardboard depends largely on budget constraints and the specific protective requirements of the product.

Choosing the Right Cardboard for Your Needs

Rigid cardboard offers superior strength and durability, making it ideal for packaging heavy or fragile items that require enhanced protection during shipping or storage. Flexible cardboard provides versatility and ease of folding, suited for products that demand lightweight, easily customizable packaging solutions. Evaluating the weight, protection level, and design requirements of your items will guide you in selecting the appropriate cardboard type to optimize functionality and cost-effectiveness.

Rigid cardboard vs Flexible cardboard Infographic

materialdif.com

materialdif.com