Corrugated cardboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength and cushioning, making it ideal for shipping and packaging fragile items. Non-corrugated cardboard, often referred to as paperboard, is a single flat sheet that offers less durability but is suitable for lightweight packaging and printing applications. Choosing between corrugated and non-corrugated cardboard depends on the required durability, protection level, and cost considerations for the specific use case.

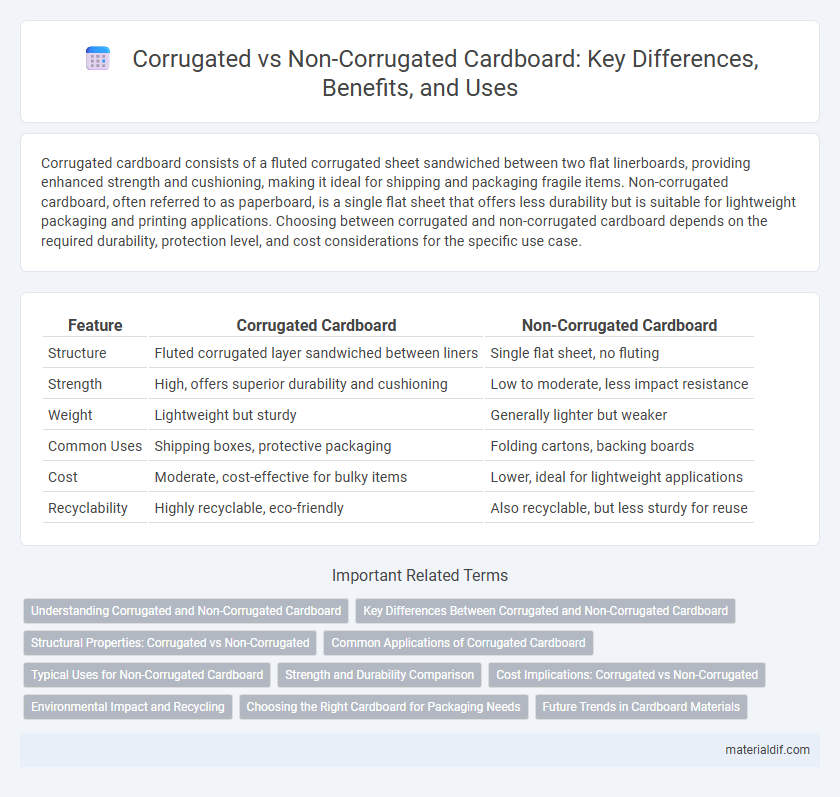

Table of Comparison

| Feature | Corrugated Cardboard | Non-Corrugated Cardboard |

|---|---|---|

| Structure | Fluted corrugated layer sandwiched between liners | Single flat sheet, no fluting |

| Strength | High, offers superior durability and cushioning | Low to moderate, less impact resistance |

| Weight | Lightweight but sturdy | Generally lighter but weaker |

| Common Uses | Shipping boxes, protective packaging | Folding cartons, backing boards |

| Cost | Moderate, cost-effective for bulky items | Lower, ideal for lightweight applications |

| Recyclability | Highly recyclable, eco-friendly | Also recyclable, but less sturdy for reuse |

Understanding Corrugated and Non-Corrugated Cardboard

Corrugated cardboard consists of a fluted corrugated sheet sandwiched between two flat linerboards, providing enhanced strength and cushioning ideal for packaging fragile items. Non-corrugated cardboard, often called paperboard or chipboard, is a single flat layer that offers less durability but is suitable for lightweight packaging and printing applications. Understanding these structural differences helps in selecting the right cardboard type based on the required strength, protection, and cost-efficiency for various shipping and packaging needs.

Key Differences Between Corrugated and Non-Corrugated Cardboard

Corrugated cardboard consists of three layers: an inner liner, an outer liner, and a fluted corrugated medium, providing superior strength and cushioning for packaging fragile items. Non-corrugated cardboard, often called paperboard, is a single flat layer, making it less durable but ideal for lightweight items and printing applications. The key difference lies in structural composition, impacting durability, insulation, and suitability for protection during shipping.

Structural Properties: Corrugated vs Non-Corrugated

Corrugated cardboard features a fluted inner layer sandwiched between two flat liners, providing superior strength, rigidity, and shock absorption compared to non-corrugated cardboard, which lacks this structural reinforcement. The fluted design in corrugated cardboard enhances its load-bearing capacity and resistance to bending, making it ideal for packaging heavy or fragile items. Non-corrugated cardboard, being flatter and less resilient, is better suited for lightweight applications such as book covers or point-of-sale displays.

Common Applications of Corrugated Cardboard

Corrugated cardboard, known for its layered structure of fluted paper sandwiched between two liners, is widely used in packaging, shipping boxes, and protective shipping containers due to its superior strength and cushioning properties. Common applications include e-commerce shipping, food packaging such as pizza boxes, and industrial packaging for fragile goods like electronics and glassware. Non-corrugated cardboard, in contrast, is typically used for lighter applications like book covers, cereal boxes, and product displays where rigidity is important but heavy-duty protection is not required.

Typical Uses for Non-Corrugated Cardboard

Non-corrugated cardboard is commonly used for applications requiring lightweight, flexible solutions such as paperboard packaging, book covers, and food packaging like cereal boxes. Its smooth surface makes it ideal for high-quality printing and product branding purposes in retail displays and consumer goods packaging. Unlike corrugated cardboard, it offers less cushioning but excels in providing an attractive, cost-effective exterior layer.

Strength and Durability Comparison

Corrugated cardboard features a fluted inner layer between two flat linerboards, providing superior strength and impact resistance compared to non-corrugated cardboard, which lacks this structural design. The enhanced durability of corrugated cardboard makes it ideal for heavy-duty packaging and shipping, as it can withstand compression, bending, and rough handling. Non-corrugated cardboard is more prone to bending and tearing, limiting its use to lightweight or decorative applications where high strength is not essential.

Cost Implications: Corrugated vs Non-Corrugated

Corrugated cardboard typically incurs higher production costs due to its layered structure, which adds durability and cushioning, making it ideal for shipping and heavy-duty packaging. Non-corrugated cardboard, or paperboard, is generally less expensive and preferred for lightweight packaging or printing applications where strength is not a primary concern. Choosing between corrugated and non-corrugated materials affects overall packaging expenses, with corrugated offering enhanced protection at a premium cost and non-corrugated providing cost savings for simpler uses.

Environmental Impact and Recycling

Corrugated cardboard features multiple layers of fluted paper sandwiched between flat linerboards, enhancing strength and recyclability compared to non-corrugated cardboard, which consists of a single flat sheet. The layered structure of corrugated cardboard improves its biodegradability and allows for efficient sorting and processing in recycling facilities, reducing landfill waste and energy consumption. Non-corrugated cardboard, often thinner and less durable, has a higher contamination risk during recycling, leading to lower material recovery rates and increased environmental impact.

Choosing the Right Cardboard for Packaging Needs

Corrugated cardboard features a fluted inner layer sandwiched between two flat linerboards, providing superior strength, cushioning, and durability ideal for shipping fragile or heavy items. Non-corrugated cardboard, such as paperboard or chipboard, is thinner and less rigid, making it suitable for lightweight packaging like retail boxes or product displays. Selecting the correct cardboard depends on factors such as protection requirements, weight of the contents, and shipping conditions to ensure optimal durability and cost-effectiveness.

Future Trends in Cardboard Materials

Corrugated cardboard continues to dominate packaging due to its superior strength, cushioning, and recyclability, but innovations in lightweight, non-corrugated materials are gaining traction for eco-friendly and cost-effective solutions. Emerging trends indicate increased use of biodegradable and bio-based polymers integrated with cardboard to enhance durability and reduce environmental impact. Advances in smart packaging technologies, such as embedded sensors in both corrugated and non-corrugated formats, are set to revolutionize supply chain transparency and product safety.

Corrugated vs Non-corrugated Infographic

materialdif.com

materialdif.com