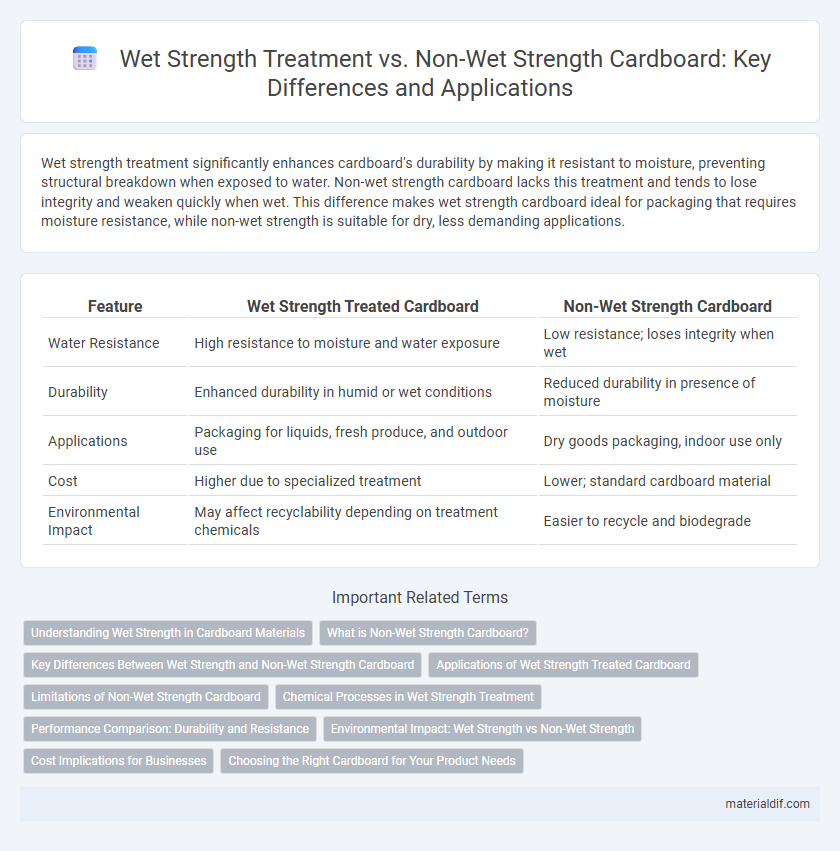

Wet strength treatment significantly enhances cardboard's durability by making it resistant to moisture, preventing structural breakdown when exposed to water. Non-wet strength cardboard lacks this treatment and tends to lose integrity and weaken quickly when wet. This difference makes wet strength cardboard ideal for packaging that requires moisture resistance, while non-wet strength is suitable for dry, less demanding applications.

Table of Comparison

| Feature | Wet Strength Treated Cardboard | Non-Wet Strength Cardboard |

|---|---|---|

| Water Resistance | High resistance to moisture and water exposure | Low resistance; loses integrity when wet |

| Durability | Enhanced durability in humid or wet conditions | Reduced durability in presence of moisture |

| Applications | Packaging for liquids, fresh produce, and outdoor use | Dry goods packaging, indoor use only |

| Cost | Higher due to specialized treatment | Lower; standard cardboard material |

| Environmental Impact | May affect recyclability depending on treatment chemicals | Easier to recycle and biodegrade |

Understanding Wet Strength in Cardboard Materials

Wet strength treatment in cardboard materials significantly enhances durability by improving resistance to water-induced weakening, preventing fiber separation when exposed to moisture. Non-wet strength cardboard lacks chemical additives that reinforce fiber bonds, resulting in reduced structural integrity under wet conditions. Understanding the impact of wet strength agents, such as polyamide-epichlorohydrin resins, is crucial for selecting cardboard applications involving moisture exposure, like packaging for food or medical products.

What is Non-Wet Strength Cardboard?

Non-wet strength cardboard lacks additives that enhance durability when exposed to moisture, making it less resistant to water damage compared to wet strength cardboard. It is commonly used for packaging dry goods where moisture exposure is minimal, prioritizing recyclability and cost-effectiveness. This type of cardboard is ideal for applications where high wet durability is unnecessary, such as shipping boxes for electronics or dry food products.

Key Differences Between Wet Strength and Non-Wet Strength Cardboard

Wet strength cardboard incorporates chemical additives like polyamide-epichlorohydrin resin to maintain structural integrity and resist water damage, making it ideal for packaging exposed to moisture. Non-wet strength cardboard lacks these additives, resulting in reduced durability and rapid weakening when wet, suitable primarily for dry, indoor applications. The key differences lie in their water resistance, durability under wet conditions, and typical use cases in industries such as food packaging versus dry goods shipping.

Applications of Wet Strength Treated Cardboard

Wet strength treated cardboard is essential for packaging products exposed to moisture, such as frozen foods, refrigerated items, and beverages. This treatment enhances the cardboard's resistance to water, maintaining structural integrity during handling and transportation in humid or wet environments. Industries relying on durable, moisture-resistant packaging prefer wet strength cardboard to ensure product protection and reduce damage risks.

Limitations of Non-Wet Strength Cardboard

Non-wet strength cardboard lacks resistance to moisture, leading to significant loss of structural integrity when exposed to water or high humidity. This limitation restricts its use in packaging applications requiring durability during transit or storage in damp environments. The absence of wet strength treatment results in increased risk of tearing, deformation, and reduced protection for contents.

Chemical Processes in Wet Strength Treatment

Wet strength treatment involves the use of chemical additives such as polyamide-epichlorohydrin (PAE) resins or melamine-formaldehyde resins that create covalent bonds between cellulose fibers, enhancing the cardboard's resistance to water-induced weakening. These chemicals form a durable network within the fiber matrix, maintaining structural integrity even when saturated, unlike non-wet strength cardboard, which relies solely on hydrogen bonding and loses strength when wet. The chemical cross-linking process is critical for packaging applications requiring moisture resistance, ensuring durability and performance under humid or wet conditions.

Performance Comparison: Durability and Resistance

Wet strength treatment significantly enhances cardboard durability by improving its resistance to water, preventing fiber breakdown and maintaining structural integrity under moisture exposure. Non-wet strength cardboard, lacking this treatment, exhibits decreased resistance to water, resulting in faster degradation and reduced load-bearing capacity when wet. Performance comparison highlights wet strength cardboard as the preferred choice for packaging requiring prolonged durability and water resistance.

Environmental Impact: Wet Strength vs Non-Wet Strength

Wet strength treatment enhances cardboard durability by adding resins that improve water resistance, but these chemicals may release harmful substances during production and disposal, increasing environmental impact. Non-wet strength cardboard lacks these additives, making it more biodegradable and easier to recycle, resulting in lower ecological footprint. Choosing non-wet strength cardboard supports sustainable packaging by minimizing chemical use and reducing pollution in the waste management process.

Cost Implications for Businesses

Wet strength treatment significantly increases the durability of cardboard, making it suitable for packaging exposed to moisture, but it also raises production costs by 15-30%. Non-wet strength cardboard is more cost-effective for dry goods, reducing material expenses and manufacturing complexity. Businesses must balance higher upfront costs of wet strength treatment against potential savings from reduced product damage and returns.

Choosing the Right Cardboard for Your Product Needs

Wet strength treatment enhances cardboard's resistance to moisture, making it ideal for packaging products exposed to humidity or liquids, such as food and beverage containers. Non-wet strength cardboard is more cost-effective and suitable for dry goods, offering adequate durability without extra chemical treatment. Choosing between these types depends on the product's storage conditions and required durability to ensure optimal protection and cost efficiency.

Wet strength treatment vs Non-wet strength Infographic

materialdif.com

materialdif.com