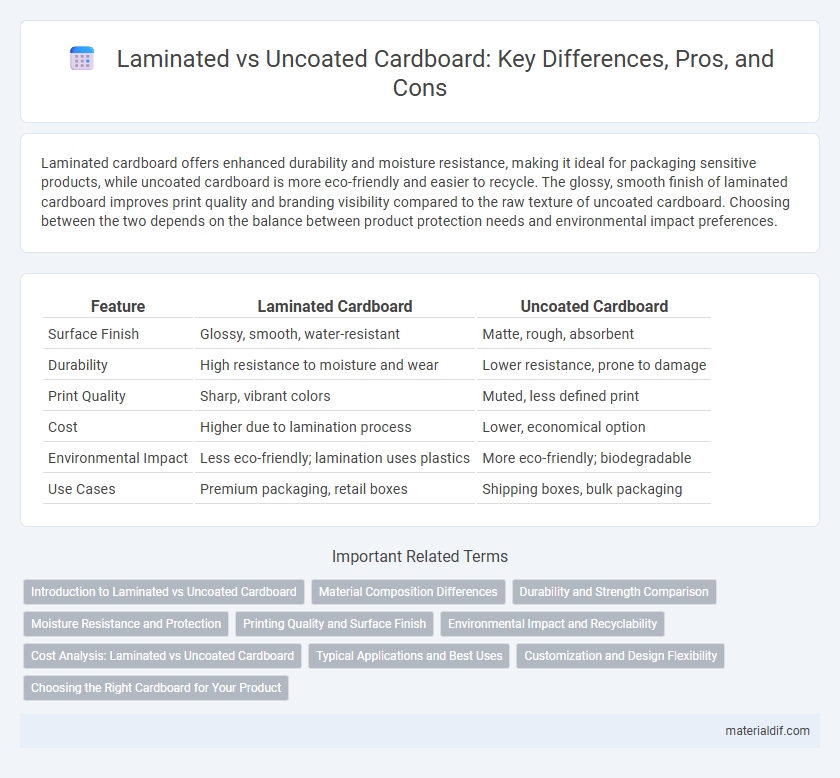

Laminated cardboard offers enhanced durability and moisture resistance, making it ideal for packaging sensitive products, while uncoated cardboard is more eco-friendly and easier to recycle. The glossy, smooth finish of laminated cardboard improves print quality and branding visibility compared to the raw texture of uncoated cardboard. Choosing between the two depends on the balance between product protection needs and environmental impact preferences.

Table of Comparison

| Feature | Laminated Cardboard | Uncoated Cardboard |

|---|---|---|

| Surface Finish | Glossy, smooth, water-resistant | Matte, rough, absorbent |

| Durability | High resistance to moisture and wear | Lower resistance, prone to damage |

| Print Quality | Sharp, vibrant colors | Muted, less defined print |

| Cost | Higher due to lamination process | Lower, economical option |

| Environmental Impact | Less eco-friendly; lamination uses plastics | More eco-friendly; biodegradable |

| Use Cases | Premium packaging, retail boxes | Shipping boxes, bulk packaging |

Introduction to Laminated vs Uncoated Cardboard

Laminated cardboard features a protective plastic or wax layer that enhances durability, moisture resistance, and visual appeal, making it ideal for packaging sensitive products. Uncoated cardboard lacks this layer, offering a more natural, eco-friendly surface suitable for printing and simple packaging needs. Choosing between laminated and uncoated cardboard depends on the required strength, finish, and environmental considerations of the project.

Material Composition Differences

Laminated cardboard features a coating layer of plastic or wax that enhances moisture resistance and durability, while uncoated cardboard is composed solely of untreated paper fibers, offering a more porous and less water-resistant surface. The lamination process typically involves bonding a thin plastic film to the cardboard base, improving stiffness and print quality. Uncoated cardboard's natural fiber composition makes it more environmentally friendly but less suitable for applications requiring protection against moisture or abrasion.

Durability and Strength Comparison

Laminated cardboard features a protective coating that significantly enhances its durability and resistance to moisture, making it ideal for packaging that requires sturdiness and longer shelf life. Uncoated cardboard, while more cost-effective and environmentally friendly, generally lacks the strength and water resistance of laminated options, leading to faster wear and vulnerability under heavy loads or humid conditions. Choosing laminated cardboard ensures better structural integrity and protection in demanding environments compared to uncoated cardboard.

Moisture Resistance and Protection

Laminated cardboard offers superior moisture resistance due to its protective plastic or wax coating, making it ideal for packaging products sensitive to humidity and water damage. Uncoated cardboard lacks this protective layer, resulting in lower resistance to moisture and less effective protection against liquid exposure. This difference significantly impacts the durability and suitability of cardboard for shipping and storage in damp or wet environments.

Printing Quality and Surface Finish

Laminated cardboard offers superior printing quality due to its smooth, glossy surface that enhances color vibrancy and detail sharpness, making it ideal for high-end packaging and promotional materials. Uncoated cardboard, with its porous and matte finish, absorbs more ink, resulting in muted colors and less precise printing, but provides a natural, rustic appearance favored for eco-friendly products. The choice between laminated and uncoated cardboard depends on the desired visual impact and brand presentation standards.

Environmental Impact and Recyclability

Laminated cardboard, often coated with plastic or wax, presents challenges for recycling due to its non-biodegradable layers, which complicate the processing and increase environmental waste. Uncoated cardboard is highly recyclable and decomposes more efficiently, making it a more sustainable choice with lower environmental impact. Selecting uncoated cardboard supports circular economy initiatives by reducing landfill contributions and facilitating easier material recovery.

Cost Analysis: Laminated vs Uncoated Cardboard

Laminated cardboard typically incurs higher production costs due to the additional materials and processes required for lamination, which enhances durability and moisture resistance. Uncoated cardboard offers a more budget-friendly option with lower manufacturing expenses but lacks the protective benefits, making it less suitable for packaging sensitive or heavy items. Cost analysis should weigh the upfront price difference against the potential savings from reduced product damage and improved shelf life provided by laminated cardboard.

Typical Applications and Best Uses

Laminated cardboard is commonly used for packaging premium products requiring moisture resistance and enhanced durability, such as luxury food containers and retail display boxes. Uncoated cardboard is ideal for applications where breathability and recyclability are prioritized, often used for shipping boxes, product partitions, and eco-friendly packaging. Choosing laminated or uncoated cardboard depends on the need for surface protection versus sustainability and cost-effectiveness in packaging solutions.

Customization and Design Flexibility

Laminated cardboard offers superior customization options with its smooth, glossy surface that enhances print quality and allows for vibrant, detailed designs. Uncoated cardboard provides greater design flexibility for eco-friendly and rustic looks, accommodating a variety of inks and finishes without compromising its natural texture. Choosing laminated cardboard suits high-impact branding needs, while uncoated cardboard supports sustainable packaging with versatile aesthetic possibilities.

Choosing the Right Cardboard for Your Product

Laminated cardboard offers enhanced durability, water resistance, and a premium finish, making it ideal for luxury packaging and products requiring extra protection. Uncoated cardboard provides a more cost-effective, eco-friendly option with a natural texture, suitable for everyday packaging and environmentally conscious brands. Selecting the right cardboard depends on product sensitivity, branding needs, and budget considerations to ensure optimal performance and presentation.

Laminated cardboard vs Uncoated cardboard Infographic

materialdif.com

materialdif.com