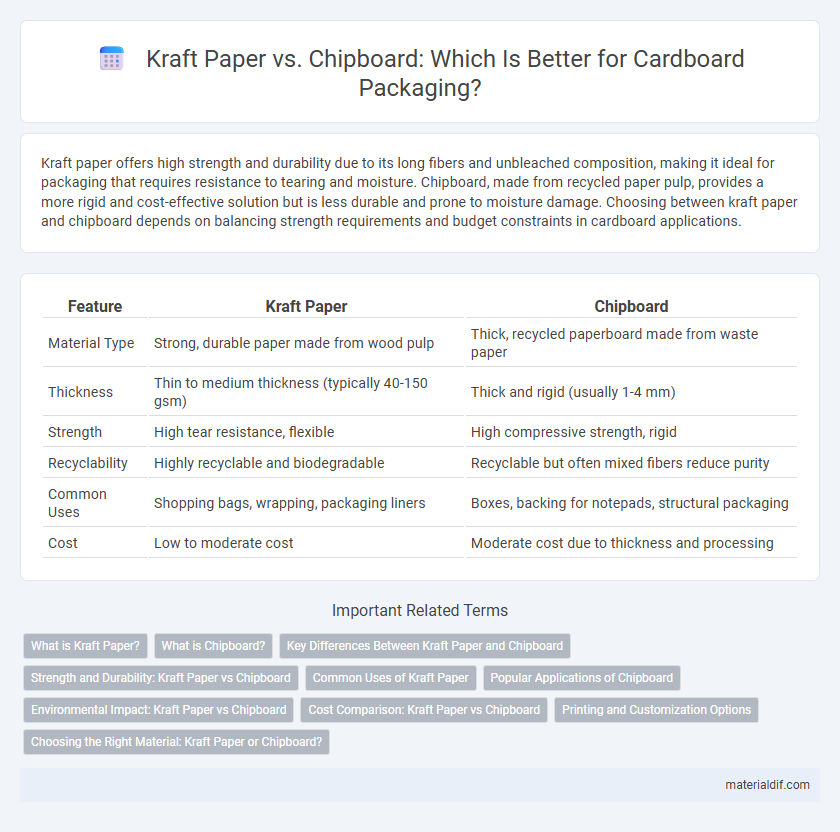

Kraft paper offers high strength and durability due to its long fibers and unbleached composition, making it ideal for packaging that requires resistance to tearing and moisture. Chipboard, made from recycled paper pulp, provides a more rigid and cost-effective solution but is less durable and prone to moisture damage. Choosing between kraft paper and chipboard depends on balancing strength requirements and budget constraints in cardboard applications.

Table of Comparison

| Feature | Kraft Paper | Chipboard |

|---|---|---|

| Material Type | Strong, durable paper made from wood pulp | Thick, recycled paperboard made from waste paper |

| Thickness | Thin to medium thickness (typically 40-150 gsm) | Thick and rigid (usually 1-4 mm) |

| Strength | High tear resistance, flexible | High compressive strength, rigid |

| Recyclability | Highly recyclable and biodegradable | Recyclable but often mixed fibers reduce purity |

| Common Uses | Shopping bags, wrapping, packaging liners | Boxes, backing for notepads, structural packaging |

| Cost | Low to moderate cost | Moderate cost due to thickness and processing |

What is Kraft Paper?

Kraft paper is a strong, durable paper made from chemical pulp produced through the kraft process, primarily using softwood fibers. It is known for its high tear resistance and excellent tensile strength, making it ideal for packaging and protective applications. Unlike chipboard, which is recycled and less sturdy, kraft paper offers superior durability and resistance to moisture and rough handling.

What is Chipboard?

Chipboard is a type of cardboard made from reclaimed paper fibers, often compressed into dense sheets with a smooth surface. Unlike Kraft paper, which is produced from virgin wood pulp and known for its strength and durability, chipboard typically contains recycled material and is less robust but more cost-effective. Commonly used in packaging, bookbinding, and backing materials, chipboard provides a sturdy yet economical solution for various manufacturing needs.

Key Differences Between Kraft Paper and Chipboard

Kraft paper is a strong, durable material made from wood pulp processed through the kraft process, characterized by its natural brown color and high tear resistance, making it ideal for packaging and wrapping. Chipboard, on the other hand, is a type of recycled paperboard composed primarily of reclaimed paper fibers, often used for backing, book covers, and rigid packaging due to its stiffness and cost-effectiveness. The main differences lie in kraft paper's superior tensile strength and resistance to moisture compared to chipboard's rigidity and recycled composition.

Strength and Durability: Kraft Paper vs Chipboard

Kraft paper offers impressive tensile strength and resistance to tearing, making it highly durable for packaging that requires flexibility and moisture resistance. Chipboard, composed of reclaimed paper fibers, provides excellent rigidity and structural support but is more prone to bending and damage under heavy loads or prolonged exposure to moisture. When selecting materials for strength and durability, kraft paper is ideal for lightweight, flexible packaging, while chipboard is best suited for applications needing firm, reusable support with moderate impact resistance.

Common Uses of Kraft Paper

Kraft paper, characterized by its high tear resistance and natural brown color, is commonly used in packaging, wrapping, and cushioning applications due to its durability and eco-friendly properties. Its versatility makes it ideal for protective packaging, paper bags, and industrial wrapping, especially in environments requiring recycled or biodegradable materials. Unlike chipboard, which is primarily used for rigid backing and structural support in products like book covers and boxes, kraft paper serves as a flexible and resilient material for everyday packaging needs.

Popular Applications of Chipboard

Chipboard is widely used in packaging, bookbinding, and furniture manufacturing due to its rigidity and cost-effectiveness. Unlike kraft paper, which is favored for wrapping and protective barriers, chipboard excels in creating sturdy backing boards, product packaging inserts, and drawer bottoms. Its dense composition provides excellent support, making it ideal for applications requiring durability and structural integrity.

Environmental Impact: Kraft Paper vs Chipboard

Kraft paper offers superior environmental benefits due to its high recyclability and biodegradable properties, reducing landfill waste and lowering carbon footprint. Chipboard, often made from recycled fibers, contributes to circular economy efforts but may contain adhesives or coatings that hinder full biodegradability. Choosing kraft paper supports sustainable packaging initiatives through renewable raw materials and energy-efficient production processes.

Cost Comparison: Kraft Paper vs Chipboard

Kraft paper is generally more expensive than chipboard due to its higher-quality fibers and durability sourced from wood pulp. Chipboard, made from recycled paper and cardboard scraps, offers a cost-effective alternative ideal for packaging and backing applications. Businesses often choose chipboard for budget-sensitive projects while opting for kraft paper when strength and premium appearance justify the higher cost.

Printing and Customization Options

Kraft paper offers a smooth surface ideal for high-quality printing and vibrant colors, making it suitable for detailed designs and branding purposes. Chipboard has a coarser texture, limiting print clarity but supports embossing and debossing techniques for distinct tactile effects. Customization options on Kraft paper include glossy, matte, and UV coatings, whereas chipboard is favored for eco-friendly packaging with simple print solutions.

Choosing the Right Material: Kraft Paper or Chipboard?

Kraft paper offers high durability and moisture resistance, making it ideal for packaging that requires strength and flexibility. Chipboard provides rigidity and cost-effectiveness, suitable for lightweight packaging and rigid inserts but lacks the tear resistance of Kraft paper. Selecting between Kraft paper and chipboard depends on the specific application needs such as strength, moisture protection, and budget constraints.

Kraft paper vs Chipboard Infographic

materialdif.com

materialdif.com