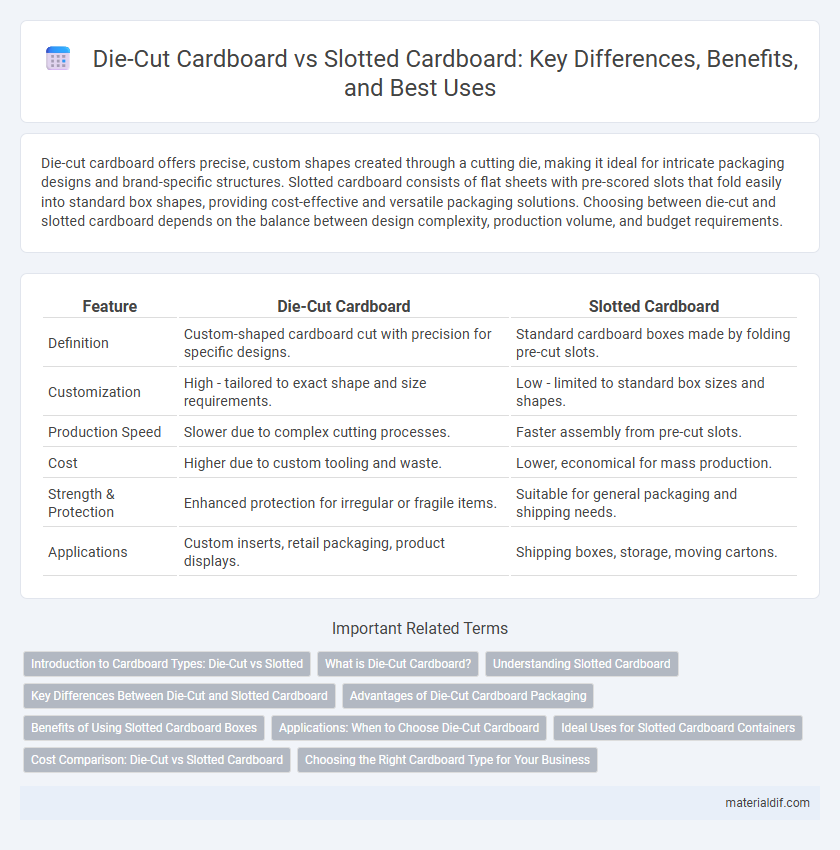

Die-cut cardboard offers precise, custom shapes created through a cutting die, making it ideal for intricate packaging designs and brand-specific structures. Slotted cardboard consists of flat sheets with pre-scored slots that fold easily into standard box shapes, providing cost-effective and versatile packaging solutions. Choosing between die-cut and slotted cardboard depends on the balance between design complexity, production volume, and budget requirements.

Table of Comparison

| Feature | Die-Cut Cardboard | Slotted Cardboard |

|---|---|---|

| Definition | Custom-shaped cardboard cut with precision for specific designs. | Standard cardboard boxes made by folding pre-cut slots. |

| Customization | High - tailored to exact shape and size requirements. | Low - limited to standard box sizes and shapes. |

| Production Speed | Slower due to complex cutting processes. | Faster assembly from pre-cut slots. |

| Cost | Higher due to custom tooling and waste. | Lower, economical for mass production. |

| Strength & Protection | Enhanced protection for irregular or fragile items. | Suitable for general packaging and shipping needs. |

| Applications | Custom inserts, retail packaging, product displays. | Shipping boxes, storage, moving cartons. |

Introduction to Cardboard Types: Die-Cut vs Slotted

Die-cut cardboard is precisely cut into custom shapes and designs, allowing for intricate folds and unique packaging forms, ideal for branding and presentation purposes. Slotted cardboard consists of flat sheets scored and folded into standard rectangular boxes, providing cost-effective and efficient packaging solutions for bulk shipping. Understanding the differences between die-cut and slotted cardboard helps businesses select the optimal packaging type based on customization needs and production volume.

What is Die-Cut Cardboard?

Die-cut cardboard is a precisely cut packaging material shaped using custom die templates to create unique and intricate designs tailored for specific product protection and presentation. Unlike slotted cardboard, which consists of simple folded flaps, die-cut cardboard offers enhanced structural integrity and aesthetic appeal through cut-outs, slots, and fold lines arranged with high precision. This method is ideal for packaging that requires specialized shapes, easy assembly, and branding opportunities.

Understanding Slotted Cardboard

Slotted cardboard consists of a single piece of corrugated fiberboard with flaps on each end that fold to form a box, making it highly efficient for packaging and shipping applications. This design allows for easy assembly, cost-effective production, and versatile use in various industries, especially for standard-sized items. Understanding the structure and benefits of slotted cardboard helps businesses optimize packaging solutions for durability and environmental sustainability.

Key Differences Between Die-Cut and Slotted Cardboard

Die-cut cardboard is precisely shaped with custom cutouts and features for specific designs, offering superior aesthetic appeal and complex structural integrity compared to slotted cardboard. Slotted cardboard consists of flat sheets scored and folded into boxes, which is more cost-effective and widely used for standard packaging needs. Key differences include die-cut cardboard's high customization and precise fit versus slotted cardboard's simplicity and faster production times.

Advantages of Die-Cut Cardboard Packaging

Die-cut cardboard packaging offers precise customization with intricate shapes and designs that enhance brand presentation and product protection. Its ability to create unique, custom-fit compartments improves product security and reduces the need for additional cushioning materials. This packaging type also allows for clean folds and seamless assembly, increasing efficiency in production and improving overall aesthetics compared to slotted cardboard.

Benefits of Using Slotted Cardboard Boxes

Slotted cardboard boxes offer enhanced durability and cost-efficiency due to their simple yet sturdy design, making them ideal for shipping and storage. Their uniform flaps allow for easy assembly without the need for extra adhesives or tools, reducing packaging time and labor expenses. The versatility of slotted cardboard boxes supports various sizes and weight capacities, providing reliable protection for a wide range of products during transit.

Applications: When to Choose Die-Cut Cardboard

Die-cut cardboard is ideal for custom packaging solutions requiring intricate shapes, precise cutouts, and specialized designs tailored to product dimensions. It is commonly used for retail displays, luxury packaging, and promotional boxes where aesthetic appeal and unique structural features are critical. Choose die-cut cardboard when packaging demands precision, customization, and branding impact beyond the capabilities of standard slotted cardboard.

Ideal Uses for Slotted Cardboard Containers

Slotted cardboard containers are ideal for shipping and storage due to their simple design and ease of assembly, making them suitable for packaging heavy or bulky items. Their interlocking flaps provide durability and protection, commonly used in industries like food distribution, electronics, and retail. These containers optimize space and cost-efficiency, supporting automated packing lines and bulk handling.

Cost Comparison: Die-Cut vs Slotted Cardboard

Die-cut cardboard typically incurs higher production costs due to its precise cutting process and customized shapes, making it ideal for specialized packaging needs. Slotted cardboard, characterized by its straight cut and fold design, offers a more cost-effective option with quicker manufacturing and less material waste. Businesses often choose slotted cardboard for bulk packaging to minimize expenses while reserving die-cut cardboard for premium presentations requiring enhanced structural integrity.

Choosing the Right Cardboard Type for Your Business

Die-cut cardboard offers precise shapes and custom designs ideal for branding and unique packaging, enhancing product presentation and customer experience. Slotted cardboard provides a cost-effective solution with easy assembly, suitable for standard shipping and storage needs. Selecting between die-cut and slotted cardboard depends on balancing budget constraints, packaging complexity, and the desired impact on consumer perception.

Die-cut cardboard vs Slotted cardboard Infographic

materialdif.com

materialdif.com