F-flute cardboard offers superior cushioning and durability, making it ideal for heavy or fragile items, while E-flute cardboard provides a thinner profile with a smoother surface suitable for detailed printing and retail packaging. The F-flute, typically measuring about 6 mm in thickness, excels in protection during shipping, whereas the E-flute, around 1.6 mm thick, is preferred for lightweight products and displays. Choosing between F-flute and E-flute cardboard depends on the balance needed between strength, print quality, and package appearance.

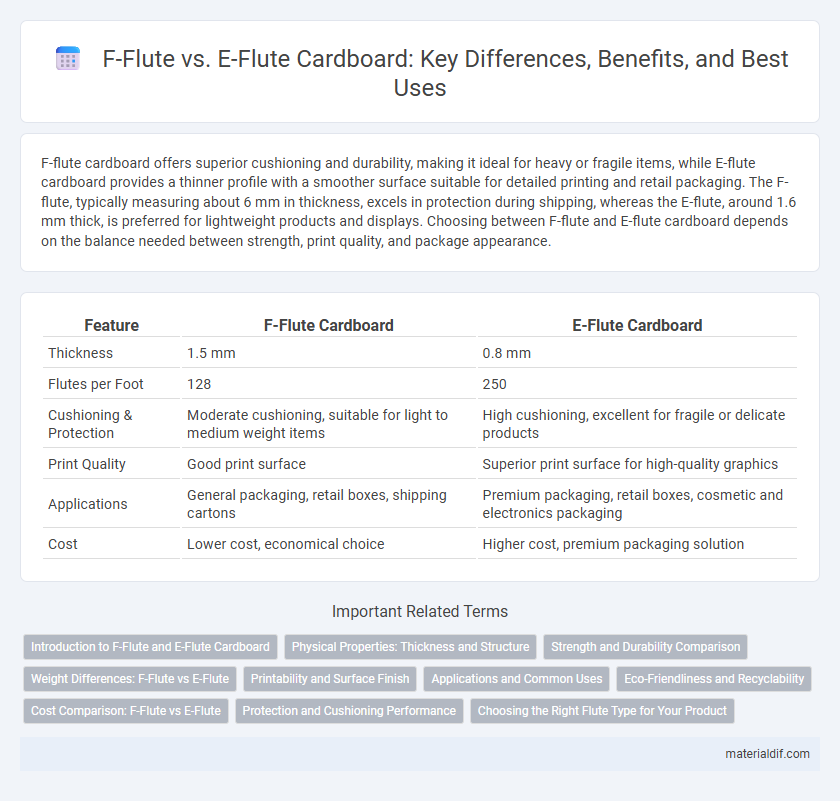

Table of Comparison

| Feature | F-Flute Cardboard | E-Flute Cardboard |

|---|---|---|

| Thickness | 1.5 mm | 0.8 mm |

| Flutes per Foot | 128 | 250 |

| Cushioning & Protection | Moderate cushioning, suitable for light to medium weight items | High cushioning, excellent for fragile or delicate products |

| Print Quality | Good print surface | Superior print surface for high-quality graphics |

| Applications | General packaging, retail boxes, shipping cartons | Premium packaging, retail boxes, cosmetic and electronics packaging |

| Cost | Lower cost, economical choice | Higher cost, premium packaging solution |

Introduction to F-Flute and E-Flute Cardboard

F-flute cardboard features a flute thickness of approximately 3.7mm, offering excellent cushioning and rigidity ideal for heavy-duty packaging and shipping applications. E-flute cardboard, with a thinner flute size around 1.5mm, provides a smoother surface suitable for high-quality printing and compact packaging needs. Both types balance strength and versatility, but F-flute excels in durability while E-flute prioritizes aesthetics and space efficiency.

Physical Properties: Thickness and Structure

F-flute cardboard typically measures around 3.2 mm in thickness, offering a thicker and more durable structure suitable for heavy-duty packaging and cushioning. E-flute cardboard has a thinner profile, approximately 1.5 mm thick, providing a smoother surface with better printability and is ideal for retail packaging and smaller, lighter products. The difference in flute size directly affects the rigidity, crush resistance, and overall protection of the cardboard, making F-flute better for strength and E-flute preferable for compactness and detail.

Strength and Durability Comparison

F-flute cardboard features a thicker profile with approximately 3/16 inch thickness, providing superior cushioning and enhanced impact resistance, making it ideal for heavy-duty packaging. E-flute cardboard, measuring about 1/16 inch thickness, offers a smoother surface for high-quality printing while maintaining moderate strength suitable for lightweight or retail packaging. The thicker F-flute excels in durability and protection during shipping, whereas E-flute prioritizes presentation with sufficient rigidity for less demanding applications.

Weight Differences: F-Flute vs E-Flute

F-flute cardboard typically weighs between 105 to 135 grams per square meter, offering thicker cushioning compared to E-flute, which ranges from 80 to 100 grams per square meter. The increased weight of F-flute contributes to superior durability and protection, making it suitable for heavy or fragile items. E-flute's lighter weight provides a more compact and efficient packaging solution while maintaining adequate strength for retail packaging.

Printability and Surface Finish

F-flute cardboard offers superior printability and a smoother surface finish compared to E-flute cardboard, making it ideal for high-quality graphics and detailed designs. Its thicker profile provides better cushioning and rigidity but may slightly reduce print sharpness due to increased surface texture. E-flute cardboard, with a finer flute structure, enables excellent print detail and a sleek surface, favored for retail packaging requiring vibrant, crisp visuals on thinner, lightweight material.

Applications and Common Uses

F-flute cardboard, known for its thickness and durability, is commonly used in shipping boxes, large product packaging, and protective shipping containers due to its excellent cushioning properties. E-flute cardboard offers a thinner profile with higher crush resistance and superior printability, making it ideal for retail packaging, point-of-purchase displays, and small consumer goods packaging. Both types serve specific applications where durability or print quality is prioritized, with F-flute excelling in heavy-duty uses and E-flute favored for its sleek appearance and detailed graphics.

Eco-Friendliness and Recyclability

F-flute cardboard offers enhanced eco-friendliness due to its thicker structure, which often requires less material for protective packaging, reducing overall waste. E-flute cardboard, being thinner and lighter, tends to use fewer raw materials and is highly recyclable, making it a sustainable choice for lightweight packaging applications. Both types are biodegradable and widely accepted in recycling programs, promoting environmental responsibility in packaging solutions.

Cost Comparison: F-Flute vs E-Flute

F-flute cardboard generally costs less than E-flute due to its thicker profile, which requires more raw material but is cheaper to produce at scale. E-flute cardboard, while thinner and more expensive per square meter, offers superior printing quality and rigidity, justifying its higher price in premium packaging applications. Businesses prioritize F-flute for cost-efficient bulk shipping, whereas E-flute is chosen for retail packaging where visual appeal and durability command higher investment.

Protection and Cushioning Performance

F-flute cardboard features a thicker profile with flute sizes around 3.6mm, offering superior cushioning and impact resistance ideal for heavy or fragile items. E-flute cardboard, with thinner flutes about 1.6mm, provides better surface smoothness and is suited for lightweight packaging that requires moderate protection. The greater thickness of F-flute enhances shock absorption and durability, whereas E-flute balances protection with a sleek appearance for retail-ready packaging.

Choosing the Right Flute Type for Your Product

F-flute cardboard offers a thicker, more cushioned structure ideal for heavy or fragile products, providing excellent impact resistance and durability during shipping. E-flute cardboard, with its thinner profile, is better suited for retail packaging and printing applications where a smooth surface and high-quality graphics are essential. Selecting the right flute type depends on your product's weight, fragility, and presentation needs, ensuring optimal protection and visual appeal.

F-flute cardboard vs E-flute cardboard Infographic

materialdif.com

materialdif.com