White-coated cardboard features a smooth, glossy surface that enhances print quality and visual appeal, making it ideal for high-end packaging and retail displays. Uncoated cardboard offers a natural, matte finish with greater breathability and recyclability, often preferred for eco-friendly packaging and shipping materials. The choice between white-coated and uncoated cardboard depends on the desired aesthetic, durability requirements, and environmental considerations.

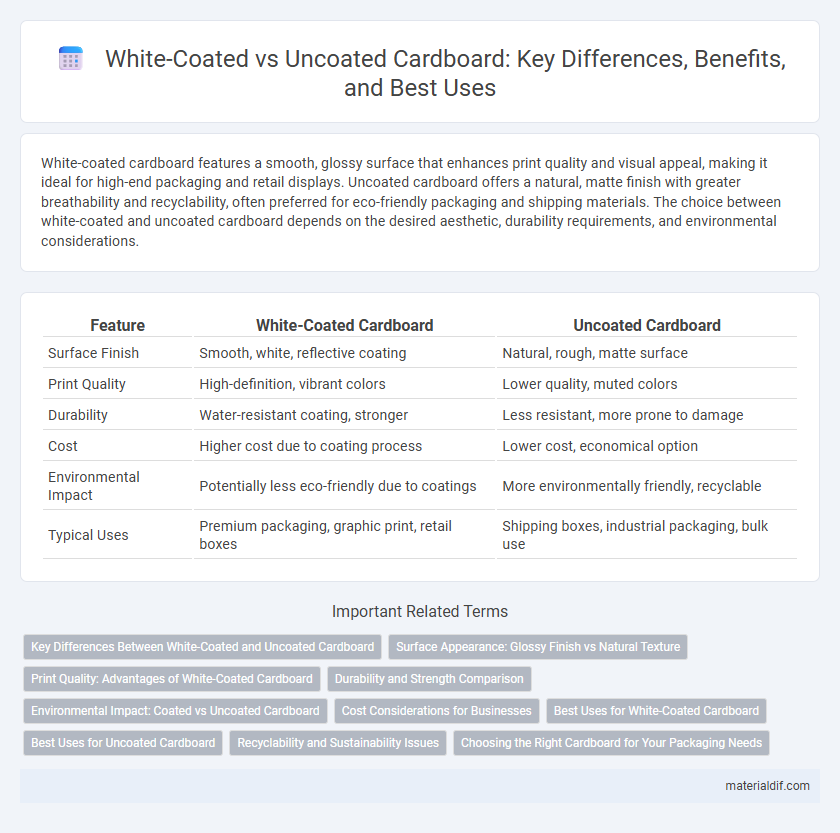

Table of Comparison

| Feature | White-Coated Cardboard | Uncoated Cardboard |

|---|---|---|

| Surface Finish | Smooth, white, reflective coating | Natural, rough, matte surface |

| Print Quality | High-definition, vibrant colors | Lower quality, muted colors |

| Durability | Water-resistant coating, stronger | Less resistant, more prone to damage |

| Cost | Higher cost due to coating process | Lower cost, economical option |

| Environmental Impact | Potentially less eco-friendly due to coatings | More environmentally friendly, recyclable |

| Typical Uses | Premium packaging, graphic print, retail boxes | Shipping boxes, industrial packaging, bulk use |

Key Differences Between White-Coated and Uncoated Cardboard

White-coated cardboard features a smooth, glossy finish created by a layer of white clay, enhancing print quality and visual appeal, making it ideal for packaging and high-end product displays. Uncoated cardboard lacks this surface treatment, resulting in a more porous, natural texture that absorbs ink differently, often used for eco-friendly or rustic packaging. The key differences lie in print vibrancy, surface texture, durability, and typical application areas.

Surface Appearance: Glossy Finish vs Natural Texture

White-coated cardboard features a glossy finish that enhances visual appeal with a smooth, polished surface ideal for high-quality printing and vibrant color reproduction. Uncoated cardboard offers a natural texture with a matte appearance, providing a rustic, organic feel preferred for eco-friendly and artisanal packaging. The choice between coated and uncoated surfaces directly impacts product presentation and consumer perception, balancing aesthetics with environmental considerations.

Print Quality: Advantages of White-Coated Cardboard

White-coated cardboard offers superior print quality due to its smooth, bright surface that enhances color vibrancy and sharpness, making images and text appear more vivid and precise. Its coating provides a uniform base that reduces ink absorption, resulting in crisper details and consistent print results. Uncoated cardboard, in contrast, absorbs more ink, often leading to duller prints with less definition and reduced visual impact.

Durability and Strength Comparison

White-coated cardboard offers enhanced durability and strength due to the additional coating layer, which provides resistance to moisture, abrasion, and wear compared to uncoated cardboard. Uncoated cardboard, while cost-effective and environmentally friendly, tends to be less robust, making it more susceptible to tearing, bending, and damage under heavy loads or prolonged use. The coating on white-coated cardboard also improves structural integrity, making it preferable for packaging applications requiring higher protection and longevity.

Environmental Impact: Coated vs Uncoated Cardboard

White-coated cardboard typically involves a layer of clay or other mineral coatings that can hinder recycling processes, leading to higher environmental impact compared to uncoated cardboard. Uncoated cardboard is more readily biodegradable and easier to recycle, reducing landfill waste and energy consumption during processing. Choosing uncoated cardboard supports sustainable packaging solutions by minimizing chemical treatments and preserving natural fiber integrity.

Cost Considerations for Businesses

White-coated cardboard generally incurs higher production costs due to the added coating process, impacting overall pricing for businesses. Uncoated cardboard offers a more budget-friendly option with lower material and manufacturing expenses, making it ideal for bulk packaging needs. Choosing between the two depends on balancing cost constraints with product presentation and durability requirements.

Best Uses for White-Coated Cardboard

White-coated cardboard offers superior print quality and enhanced visual appeal, making it ideal for high-end packaging, retail displays, and product labels. Its smooth, glossy surface resists moisture and dirt, ensuring durability in food packaging and cosmetic boxes. This type of cardboard is preferred where aesthetic presentation and protection are critical.

Best Uses for Uncoated Cardboard

Uncoated cardboard is ideal for packaging applications requiring strong, durable materials such as shipping boxes and product containers due to its natural texture and increased strength. It offers excellent printability for eco-friendly branding, making it popular for food packaging, retail displays, and letter trays. Its porous surface allows for better adhesion of adhesives and coatings, enhancing its versatility in industrial and commercial uses.

Recyclability and Sustainability Issues

White-coated cardboard often contains a plastic or clay-based coating that impedes recyclability by contaminating paper recycling streams, resulting in higher processing costs and reduced fiber recovery. Uncoated cardboard is more easily recycled due to its lack of surface treatments, promoting better fiber reclamation and more sustainable lifecycle outcomes. Sustainability concerns with white-coated options include increased resource use and potential landfill persistence, while uncoated cardboard aligns better with circular economy principles by facilitating biodegradability and efficient recycling.

Choosing the Right Cardboard for Your Packaging Needs

White-coated cardboard offers a smooth surface that enhances print quality and provides resistance to moisture, making it ideal for premium packaging and retail presentation. Uncoated cardboard features a more natural texture and higher absorbency, suitable for eco-friendly packaging or products where a rustic look is desired. Selecting the right cardboard depends on factors like branding requirements, durability, and environmental impact to ensure the packaging aligns with product needs and consumer expectations.

White-coated cardboard vs Uncoated cardboard Infographic

materialdif.com

materialdif.com