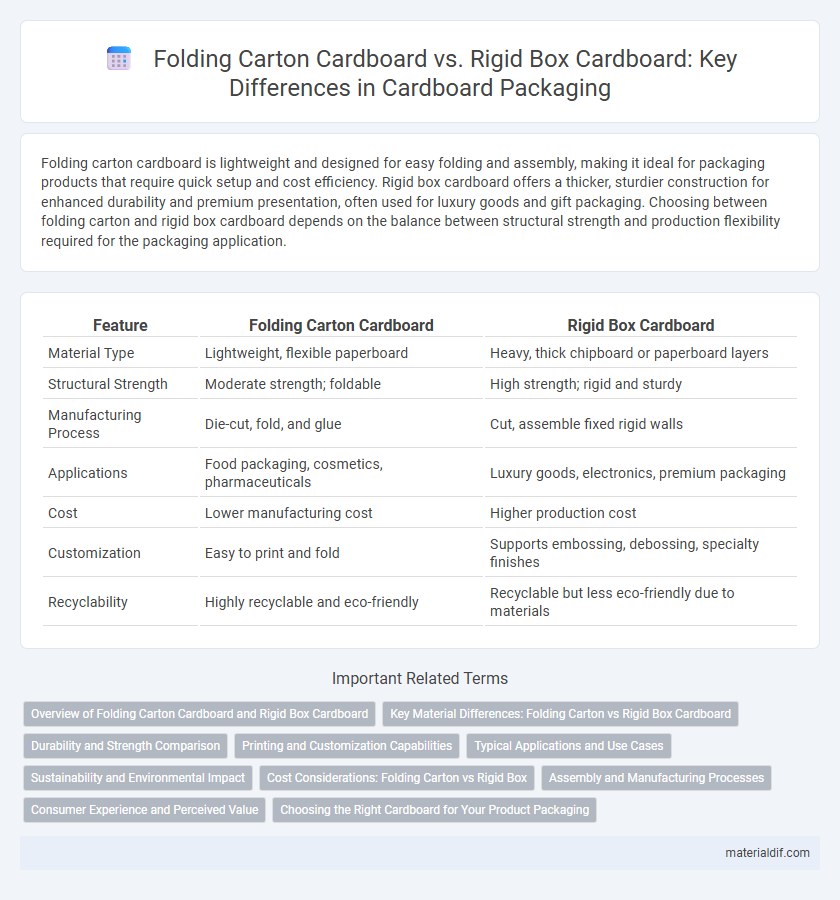

Folding carton cardboard is lightweight and designed for easy folding and assembly, making it ideal for packaging products that require quick setup and cost efficiency. Rigid box cardboard offers a thicker, sturdier construction for enhanced durability and premium presentation, often used for luxury goods and gift packaging. Choosing between folding carton and rigid box cardboard depends on the balance between structural strength and production flexibility required for the packaging application.

Table of Comparison

| Feature | Folding Carton Cardboard | Rigid Box Cardboard |

|---|---|---|

| Material Type | Lightweight, flexible paperboard | Heavy, thick chipboard or paperboard layers |

| Structural Strength | Moderate strength; foldable | High strength; rigid and sturdy |

| Manufacturing Process | Die-cut, fold, and glue | Cut, assemble fixed rigid walls |

| Applications | Food packaging, cosmetics, pharmaceuticals | Luxury goods, electronics, premium packaging |

| Cost | Lower manufacturing cost | Higher production cost |

| Customization | Easy to print and fold | Supports embossing, debossing, specialty finishes |

| Recyclability | Highly recyclable and eco-friendly | Recyclable but less eco-friendly due to materials |

Overview of Folding Carton Cardboard and Rigid Box Cardboard

Folding carton cardboard is typically made from paperboard that is lightweight yet sturdy, allowing for easy folding and shaping into various packaging forms, widely used for consumer goods like cereals and cosmetics. Rigid box cardboard, also known as set-up boxes, consists of thicker, multi-layered paperboard that provides enhanced durability and structural integrity, ideal for luxury packaging such as electronics and high-end apparel. Both materials offer distinct benefits in terms of protection, appearance, and customization, catering to different packaging needs and product positioning strategies.

Key Material Differences: Folding Carton vs Rigid Box Cardboard

Folding carton cardboard is typically made from paperboard with a thickness ranging from 0.3 to 0.8 mm, offering lightweight and flexible properties suitable for packaging lightweight products. Rigid box cardboard, also known as chipboard or set-up box material, consists of thick layers of compressed paper or wood pulp, measuring 1.5 mm or more, providing durability and structural strength for premium packaging. The key material differences lie in folding carton's thin, bendable composition versus rigid box's robust, thick construction designed to protect heavy or delicate items.

Durability and Strength Comparison

Folding carton cardboard typically offers moderate durability, suitable for lightweight packaging needs, while rigid box cardboard provides superior strength and robustness for protecting heavier or fragile items. The structural integrity of rigid boxes comes from thicker materials and reinforced edges, making them more resistant to crushing and bending. Folding cartons, although less durable, are cost-effective and easier to fold, making them ideal for mass-produced products with less demanding protection requirements.

Printing and Customization Capabilities

Folding carton cardboard offers versatile printing options with high-quality digital and offset printing, allowing vibrant colors and detailed graphics ideal for retail packaging. Rigid box cardboard provides excellent structural integrity for luxury packaging but may have limitations in printing methods due to thicker materials, often requiring specialized finishing techniques like foil stamping and embossing for customization. Both materials support customization, but folding cartons excel in full-surface printability, while rigid boxes highlight tactile and premium finishes.

Typical Applications and Use Cases

Folding carton cardboard is widely used for packaging consumer goods such as cereals, pharmaceuticals, and cosmetics due to its lightweight and easy-to-fold properties. Rigid box cardboard is favored for high-end products like luxury chocolates, electronics, and jewelry because of its sturdy construction and premium feel. Folding cartons excel in cost-effective mass production, while rigid boxes provide superior protection and an upscale presentation for delicate or valuable items.

Sustainability and Environmental Impact

Folding carton cardboard is typically made from recycled paper fibers, offering a more eco-friendly option due to its lightweight structure and ease of recycling, which reduces waste and carbon footprint. Rigid box cardboard, while providing superior durability and protection, often involves more materials and energy during production, resulting in a higher environmental impact and lower recyclability. Choosing folding carton cardboard supports sustainable packaging initiatives by minimizing resource consumption and promoting circular waste management.

Cost Considerations: Folding Carton vs Rigid Box

Folding carton cardboard typically costs less than rigid box cardboard due to its lightweight structure and simpler manufacturing process. Rigid box cardboard involves thicker, multi-layered materials contributing to higher expenses in production and transportation. Cost considerations often favor folding cartons for budget-conscious packaging needs, while rigid boxes suit premium products requiring durability and luxury appeal.

Assembly and Manufacturing Processes

Folding carton cardboard is designed for streamlined assembly with die-cut and scored sheets that enable quick folding and gluing processes, making it ideal for mass production and automated packaging lines. Rigid box cardboard, in contrast, requires complex manufacturing involving multiple layers of thick paperboard glued together for enhanced sturdiness, followed by hand-assembled or semi-automated construction that enhances durability but increases production time. The precision in die-cutting and gluing techniques differentiates folding cartons' efficient scalability from the premium build quality found in rigid boxes.

Consumer Experience and Perceived Value

Folding carton cardboard offers lightweight, flexible packaging that enhances consumer convenience and ease of handling, often favored for everyday products due to its affordability. Rigid box cardboard provides a sturdy, premium feel that elevates perceived value through durability and a luxurious unboxing experience, making it ideal for high-end or gift items. The choice between folding cartons and rigid boxes significantly influences consumer perception by balancing cost-efficiency with the desire for quality presentation.

Choosing the Right Cardboard for Your Product Packaging

Folding carton cardboard offers lightweight, cost-effective packaging ideal for products requiring easy assembly and minimal protection, commonly used in food and cosmetics packaging. Rigid box cardboard provides superior durability and premium presentation, suitable for high-value items like electronics and luxury goods, ensuring enhanced protection during shipping. Selecting the right cardboard depends on balancing product fragility, brand image, and budget to optimize packaging effectiveness and customer experience.

Folding carton cardboard vs Rigid box cardboard Infographic

materialdif.com

materialdif.com