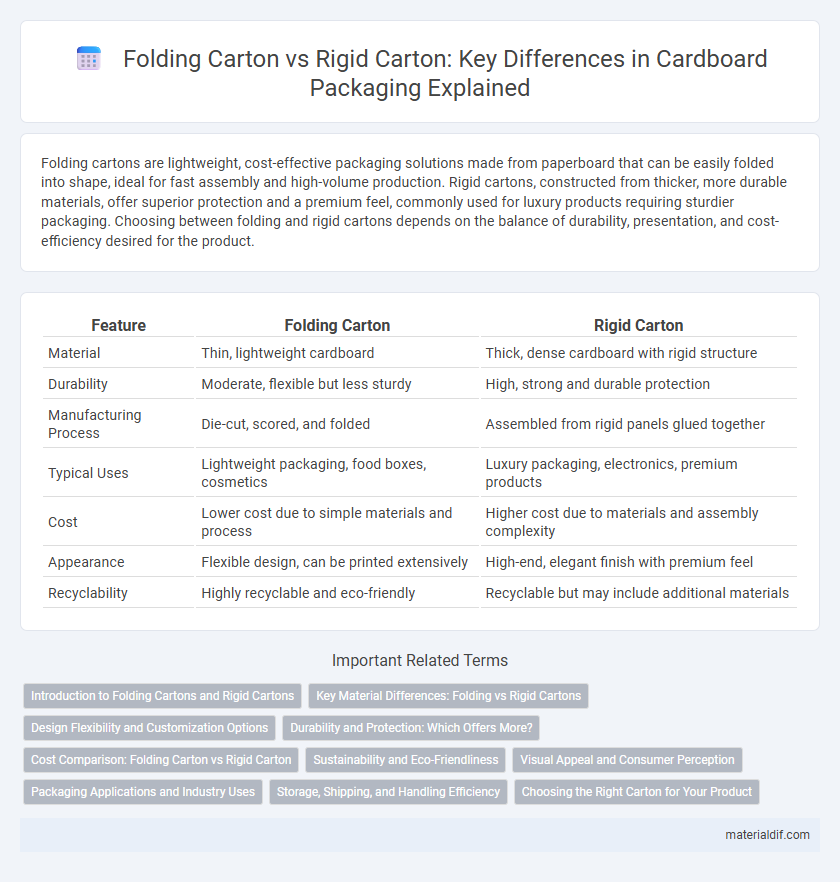

Folding cartons are lightweight, cost-effective packaging solutions made from paperboard that can be easily folded into shape, ideal for fast assembly and high-volume production. Rigid cartons, constructed from thicker, more durable materials, offer superior protection and a premium feel, commonly used for luxury products requiring sturdier packaging. Choosing between folding and rigid cartons depends on the balance of durability, presentation, and cost-efficiency desired for the product.

Table of Comparison

| Feature | Folding Carton | Rigid Carton |

|---|---|---|

| Material | Thin, lightweight cardboard | Thick, dense cardboard with rigid structure |

| Durability | Moderate, flexible but less sturdy | High, strong and durable protection |

| Manufacturing Process | Die-cut, scored, and folded | Assembled from rigid panels glued together |

| Typical Uses | Lightweight packaging, food boxes, cosmetics | Luxury packaging, electronics, premium products |

| Cost | Lower cost due to simple materials and process | Higher cost due to materials and assembly complexity |

| Appearance | Flexible design, can be printed extensively | High-end, elegant finish with premium feel |

| Recyclability | Highly recyclable and eco-friendly | Recyclable but may include additional materials |

Introduction to Folding Cartons and Rigid Cartons

Folding cartons are lightweight, made from paperboard, and designed to be folded flat for efficient shipping and storage, commonly used in packaging for consumer goods like cosmetics and food products. Rigid cartons consist of thicker, more durable materials, often featuring a solid structure that does not collapse, providing premium protection and presentation for luxury items such as electronics and high-end gifts. Both carton types offer unique benefits in terms of strength, cost, and visual appeal, influencing their application across diverse industries.

Key Material Differences: Folding vs Rigid Cartons

Folding cartons primarily use lightweight, flexible paperboard that allows for easy folding and assembly, making them cost-effective and suitable for mass production. Rigid cartons consist of thick, dense cardboard or chipboard, providing superior strength, durability, and protection for high-end or fragile products. The key material difference lies in the thickness and structural rigidity, with folding cartons favoring versatility and economic efficiency, while rigid cartons emphasize premium quality and enhanced product safety.

Design Flexibility and Customization Options

Folding cartons offer exceptional design flexibility due to their ability to be easily printed, die-cut, and folded into various shapes and sizes, enabling high customization for branding and product presentation. Rigid cartons provide limited design adaptability but excel in structural strength and luxury appeal, often customized with specialty finishes like embossing, foil stamping, and magnetic closures for premium packaging. Choosing between folding and rigid cartons depends on the desired balance between customization intricacies and durability requirements.

Durability and Protection: Which Offers More?

Folding cartons provide moderate durability and protection, suitable for lightweight products with minimal impact during transit. Rigid cartons, made from thicker and more robust materials, offer superior durability and enhanced protection against crushing, moisture, and tampering. For high-value or fragile items, rigid cartons are the preferred packaging choice due to their structural strength and cushioning capabilities.

Cost Comparison: Folding Carton vs Rigid Carton

Folding cartons generally offer a more cost-effective packaging solution due to their lightweight materials and efficient production process, making them ideal for high-volume runs. Rigid cartons, constructed from thicker, sturdier cardboard, incur higher manufacturing and material costs but provide superior durability and a premium feel. Businesses must weigh initial expenses against brand positioning and product protection needs when choosing between folding and rigid cartons.

Sustainability and Eco-Friendliness

Folding cartons are typically made from thinner paperboard, making them more sustainable due to lower material use and easier recyclability compared to rigid cartons, which rely on thicker, non-recyclable layers. The lightweight nature of folding cartons reduces transportation emissions, enhancing their eco-friendly profile. Rigid cartons, while offering superior durability, require more resources and generate higher waste, posing challenges for sustainability initiatives in packaging.

Visual Appeal and Consumer Perception

Folding cartons offer vibrant graphics and intricate designs due to their printable paperboard material, enhancing visual appeal and attracting consumers with colorful, customizable packaging. Rigid cartons convey premium quality and durability, often perceived as high-end by consumers because of their sturdy construction and smooth, elegant finishes. Consumer perception strongly favors folding cartons for affordability and variety, while rigid cartons are associated with luxury products and gift packaging.

Packaging Applications and Industry Uses

Folding cartons, made from lightweight paperboard, are widely used in packaging applications for consumer goods such as cosmetics, pharmaceuticals, and food products due to their cost-effectiveness and ease of assembly. Rigid cartons, constructed from thicker and more durable materials like chipboard or grayboard, are preferred in luxury packaging for electronics, high-end cosmetics, and premium alcohol, providing superior protection and an upscale presentation. Industry uses for folding cartons span fast-moving consumer goods sectors requiring efficient, mass packaging, while rigid cartons serve industries emphasizing product protection, structural integrity, and premium branding.

Storage, Shipping, and Handling Efficiency

Folding cartons offer superior storage efficiency due to their flat, collapsible design, significantly reducing warehouse space requirements compared to rigid cartons. In shipping, folding cartons minimize freight costs by occupying less volume, while rigid cartons, being bulky and non-collapsible, demand more space and increase transportation expenses. Handling efficiency favors folding cartons as they are lightweight and easy to assemble on demand, whereas rigid cartons provide enhanced protection but require more effort and storage area before use.

Choosing the Right Carton for Your Product

Folding cartons offer lightweight, cost-effective packaging solutions ideal for products requiring quick assembly and efficient shipping, while rigid cartons provide superior durability and premium presentation for high-end or fragile items. Choosing the right carton depends on product protection needs, branding emphasis, and budget constraints, with folding cartons favored for versatility and rigid cartons for luxury appeal. Understanding material properties, print quality, and structural integrity helps optimize packaging performance and customer perception.

Folding carton vs Rigid carton Infographic

materialdif.com

materialdif.com