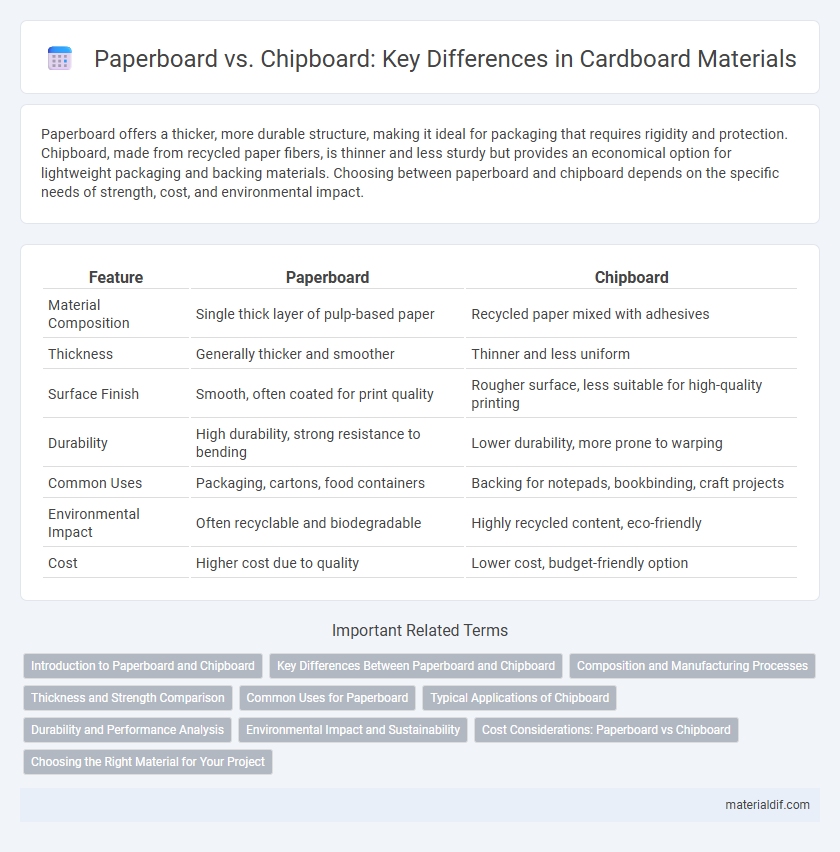

Paperboard offers a thicker, more durable structure, making it ideal for packaging that requires rigidity and protection. Chipboard, made from recycled paper fibers, is thinner and less sturdy but provides an economical option for lightweight packaging and backing materials. Choosing between paperboard and chipboard depends on the specific needs of strength, cost, and environmental impact.

Table of Comparison

| Feature | Paperboard | Chipboard |

|---|---|---|

| Material Composition | Single thick layer of pulp-based paper | Recycled paper mixed with adhesives |

| Thickness | Generally thicker and smoother | Thinner and less uniform |

| Surface Finish | Smooth, often coated for print quality | Rougher surface, less suitable for high-quality printing |

| Durability | High durability, strong resistance to bending | Lower durability, more prone to warping |

| Common Uses | Packaging, cartons, food containers | Backing for notepads, bookbinding, craft projects |

| Environmental Impact | Often recyclable and biodegradable | Highly recycled content, eco-friendly |

| Cost | Higher cost due to quality | Lower cost, budget-friendly option |

Introduction to Paperboard and Chipboard

Paperboard is a thick, sturdy material made from multiple layers of cellulose fibers, commonly used in packaging for its durability and printability. Chipboard, a type of paperboard, is produced from recycled paper fibers and is typically less dense and more cost-effective, making it ideal for lightweight packaging and backing applications. Both materials offer versatility but differ significantly in composition, strength, and typical uses.

Key Differences Between Paperboard and Chipboard

Paperboard is a thicker, multi-ply material made from high-quality virgin fibers, offering excellent durability and a smooth surface ideal for printing and packaging. Chipboard, composed primarily of recycled paper fibers with lower density, provides a more economical yet less sturdy option, often used for backing or interior packaging. The key differences lie in their fiber quality, thickness, strength, and intended applications, with paperboard excelling in premium packaging and chipboard serving cost-effective, lightweight structural needs.

Composition and Manufacturing Processes

Paperboard consists primarily of multiple layers of pulped wood fibers, offering a smooth surface achieved through a refined manufacturing process involving pressing and drying, making it ideal for packaging with high print quality. Chipboard is manufactured by recycling shredded paper and cardboard waste, resulting in a dense material with a rougher texture due to the less refined fiber composition and simpler pressing techniques. The difference in fiber quality and layering significantly impacts durability, surface finish, and suitability for various packaging applications.

Thickness and Strength Comparison

Paperboard typically offers greater thickness and strength compared to chipboard, making it suitable for applications requiring durability and structural integrity. Thickness of paperboard usually ranges from 0.4 mm to 2 mm, while chipboard is thinner, often between 0.3 mm and 1.5 mm, resulting in less rigidity. The higher density and layered construction of paperboard enhance its load-bearing capacity, distinguishing it from the more brittle and less dense chipboard.

Common Uses for Paperboard

Paperboard is commonly used in packaging for consumer goods like cereal boxes, shoe boxes, and cosmetic packaging due to its lightweight and durable properties. It serves extensively in printing applications, such as posters and postcards, benefiting from its smooth surface for high-quality graphics. The food industry relies on paperboard for cartons and trays, where product protection and recyclability are essential.

Typical Applications of Chipboard

Chipboard, a dense and stiff material made from recycled paper, is commonly used in applications such as backing for notepads, book covers, and product packaging due to its durability and cost-effectiveness. Its rigidity makes it suitable for protective packaging inserts, rigid boxes, and furniture components like drawer bottoms or backing boards. Chipboard's versatile nature allows it to serve in arts and crafts projects, offering a sturdy base while maintaining affordability.

Durability and Performance Analysis

Paperboard exhibits superior durability and stiffness compared to chipboard, making it ideal for packaging that requires structural strength and resistance to impact. Chipboard, often composed of recycled fibers, is less dense and offers lower performance in terms of moisture resistance and load-bearing capacity. Performance analysis reveals that paperboard outperforms chipboard in protecting sensitive products, maintaining shape integrity, and providing a premium finish suitable for high-end packaging applications.

Environmental Impact and Sustainability

Paperboard, made primarily from virgin fibers, offers higher durability but has a significant environmental impact due to deforestation and energy-intensive production processes. Chipboard, composed mainly of recycled paper fibers, usually presents a lower carbon footprint and promotes circular economy practices by reducing waste and conserving natural resources. Both materials contribute to sustainability efforts, yet chipboard's reliance on post-consumer content makes it a preferable choice for eco-friendly packaging solutions.

Cost Considerations: Paperboard vs Chipboard

Paperboard generally incurs higher costs than chipboard due to its superior quality and smooth surface, which make it ideal for premium packaging and printing applications. Chipboard, made from recycled paper and lower-grade fibers, offers a cost-effective alternative for secondary packaging, carton backing, and insulation. Businesses must weigh durability and aesthetic appeal against budget constraints when selecting between paperboard and chipboard.

Choosing the Right Material for Your Project

Paperboard offers a smooth surface and excellent printability, ideal for high-quality packaging and detailed graphics. Chipboard is heavier, made from recycled paper stock, providing robust rigidity and cost-effectiveness for structural applications like backing or inserts. Selecting the right material depends on your project's priorities for appearance, durability, and budget constraints.

Paperboard vs Chipboard Infographic

materialdif.com

materialdif.com